High-pressure nitrogen blast cracking permeability increase experimental device and method

A technology of high-pressure nitrogen and experimental equipment, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of not considering the effect of nitrogen volume fracturing, and achieve wide practicability, strong stability, Easy to use and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

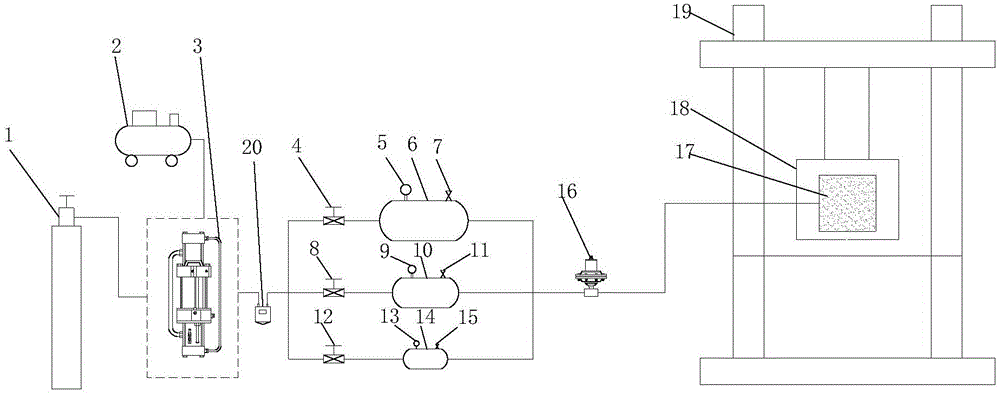

[0016] Embodiment 1: taking the cement test piece as the example of the blasted medium 17, the specific method of use of the experimental device of the present invention is:

[0017] 1. Use stones, cement, and sand as model materials and mix them with each other to produce a total of 5 cubic cement specimens 17 with a compressive strength of 1.97MPa and a tensile strength of 0.19MPa. The size of the cement specimen 17 is just right Can be placed in the triaxial pressure chamber 18.

[0018] 2. Use cement, resin and other sealing materials to solidify one end of the air guide hose in the air explosion hole outside the triaxial pressure chamber 18, and connect the other end of the air guide hose to the high-pressure air bag through a plug-in connection.

[0019] 3. The triaxial pressure testing machine 19 performs stress loading on the cement specimen 17 in both horizontal and vertical directions. When the axial pressure of the cement specimen 17 is 1.0 MPa and the confining pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com