Pulse wave reinforced hydraulic fracturing evaluation experimental device and method

An experimental device and hydraulic fracturing technology, applied in the field of hydraulic fracturing, can solve the problems of lack of quantitative relationship, single fracture, large pump injection, etc., and achieve the effect of enhancing the experimental range, improving the reservoir productivity, and enhancing the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

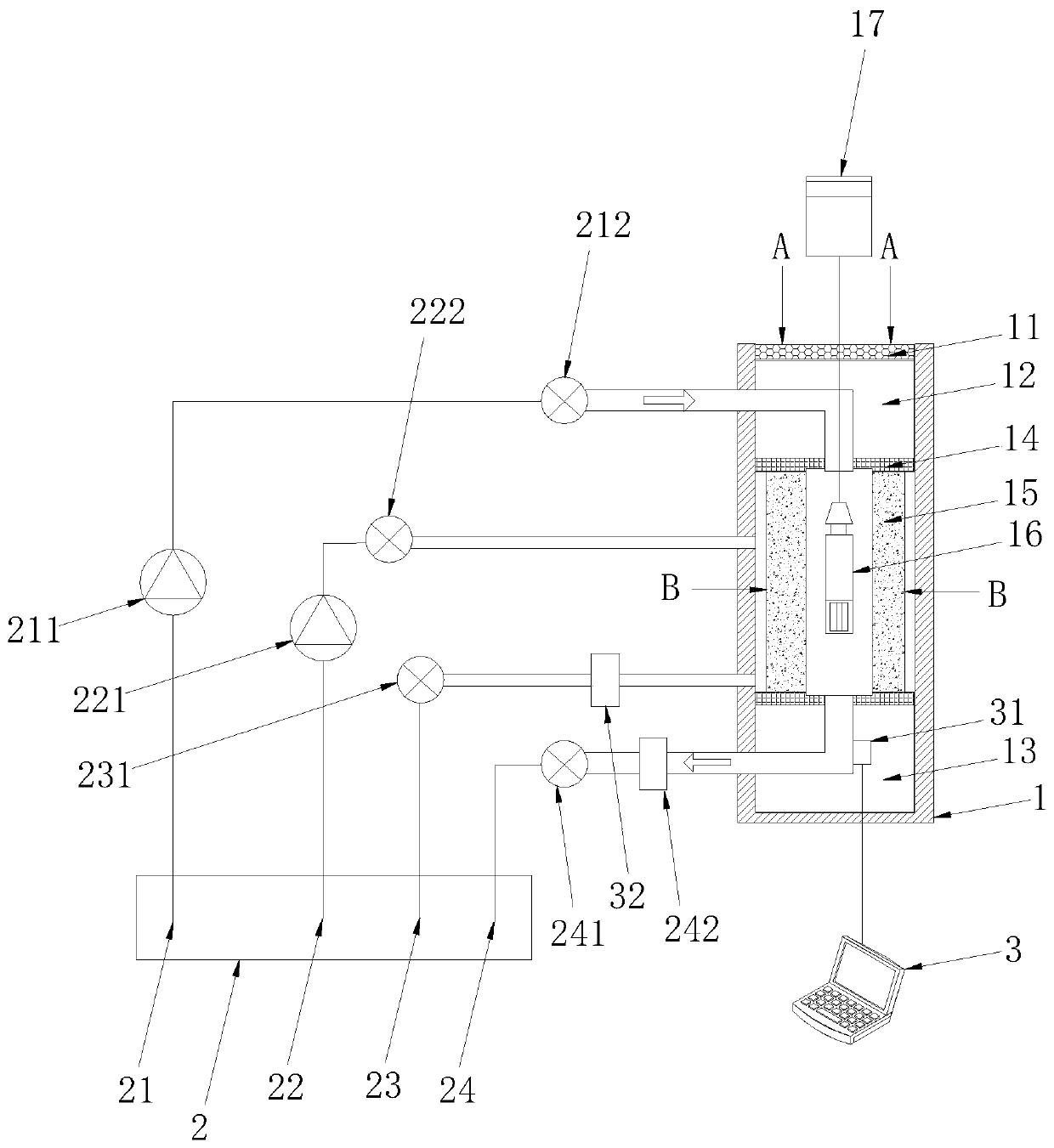

[0037] Embodiment 1: A kind of pulse wave enhanced hydraulic fracturing evaluation experimental device, such asfigure 1 As shown, it includes a triaxial pressure experimental device, a fluid delivery control device, and an experimental parameter monitoring device. The triaxial pressure test device includes a casing 1 with an opening at the top, a shock wave generator 16 and a power control cabinet 17 electrically connected to the shock wave generator 16 , and a cable sealer 11 is sealingly connected to the top of the casing 1 . A rock sample 15 is arranged coaxially inside the casing 1 , and a shock wave generator 16 is placed in the rock sample 15 . The top end of the casing 1 is provided with an upper base 12 which is in conflict with the top surface of the rock sample 15 , and the bottom end of the casing 1 is provided with a lower base 13 which is in conflict with the bottom surface of the rock sample 15 .

[0038] The fluid delivery control device includes a fracturing fl...

Embodiment 2

[0045] Embodiment 2: a kind of pulse wave enhanced hydraulic fracturing evaluation test method, such as figure 1 shown, including the following steps:

[0046] Step 1: Store the prepared fracturing fluid that meets the experimental requirements in the fracturing fluid tank 2 for future use, and select and prepare test rock samples 15 that meet the experimental requirements for future use.

[0047] Step 2, measuring the permeability Kb of the rock sample 15 before fracturing. Put the test rock sample 15 before fracturing into the casing 1, select formation water or standard brine as the flow test medium, close the first regulating valve 212, open the third regulating valve 231, and make the test medium pressurize from the bottom of the casing 1. The rock sample 15 started to be displaced. The flow and pressure of the fluid are controlled through the third regulating valve 231. When the flow and pressure difference tend to be stable, the permeability of the rock sample 15 is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com