Quick-connection type center rod pulling structure and split type fidelity corer pressure experiment structure

A quick-connect and plug-in structure technology, which is applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problems of damage to the pressure-holding experimental cabin and untrue experimental results, so as to prevent damage, reliable performance, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

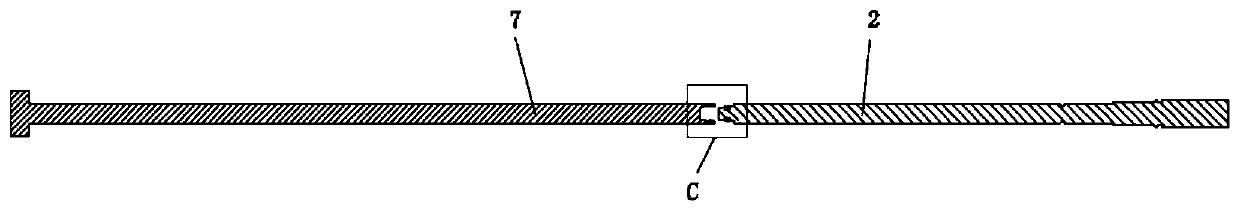

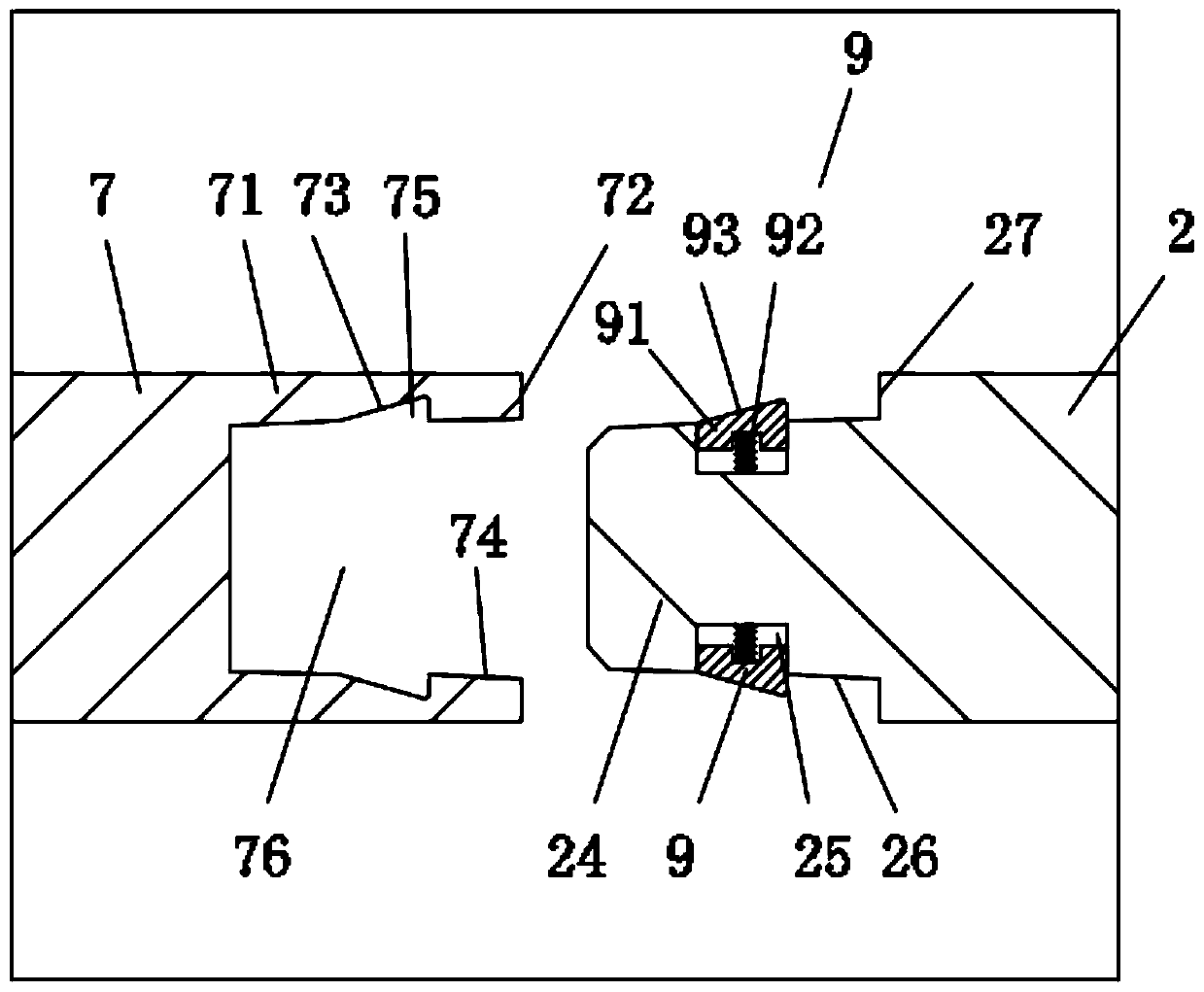

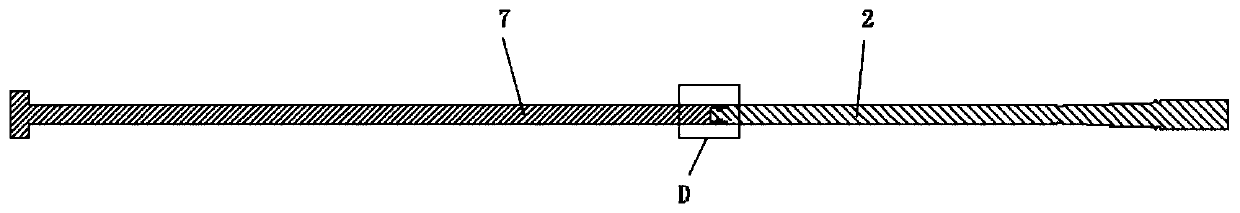

[0057] like Figure 1-6 As shown, the quick-connect central rod pulling structure disclosed in the present invention includes a pull rod 7, a central rod 2 and a quick plug-in structure. The quick plug structure includes a plug part 24 , a socket part 71 adapted to the plug part 24 and at least two spring buckles 9 . The plug part 24 and the socket part 71 are respectively connected with one of the pull rod 7 and the central rod 2 . Connected here means that two separate parts are connected together or manufactured in one piece. Link to each other with plug part 24 and central rod 2, jack part 71 is connected with pull rod 7 as example, plug part 24 can be manufactured integrally with central rod 2, and plug part 24 and central rod 2 also can be two independent parts, connect then to form A whole. Certainly, the plug part 24 can also be connected with the pull rod 7 , and the socket part 71 is connected with the central rod 2 .

[0058] The plug part 24 and the socket part...

specific Embodiment approach 2

[0069] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, in this embodiment, the plug portion 24 is integrally manufactured with the pull rod 7 , and the socket portion 71 is integrally manufactured with the central rod 2 of the pull rod 7 . The principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

specific Embodiment approach 3

[0071] The difference between this embodiment mode and embodiment mode 1 or embodiment 2 is that: Image 6 As shown, in this embodiment, the spring buckle 9 is installed on the socket portion 71 . The spring buckle 9 includes a block 91 and a radially arranged spring 92 . The jack portion 71 is provided with a jack 76, the wall 74 of the jack 76 has a groove 25 for the block 91 to avoid, one end of the spring 92 is fixedly connected to the groove wall of the groove 25, and the other end of the spring 92 is fixedly connected to the block 91 Under the action of the spring 92, a part of the block 91 is located in the groove 25, and the other part of the block 91 protrudes from the wall 74 of the socket 76.

[0072] The outer side of the block 91 is a slope 93, so that when the plug part 24 is plugged into the socket part 71, the axial force of the plug part 24 acting on the slope 93 can generate a radial component force, and then push the block 91 to move radially to fully subm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com