Oil bath type internal and external temperature control fidelity coring device experimental platform

An experimental platform and corer technology, which is applied to instruments, undisturbed core extraction devices, isolation devices, etc., can solve the problems of inability to verify the pressure-resistant performance of the pressure-holding chamber, inability to simulate high temperature environments, and damage to the pressure-holding experimental chamber. Reliable test results, shortening experiment time and reducing experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

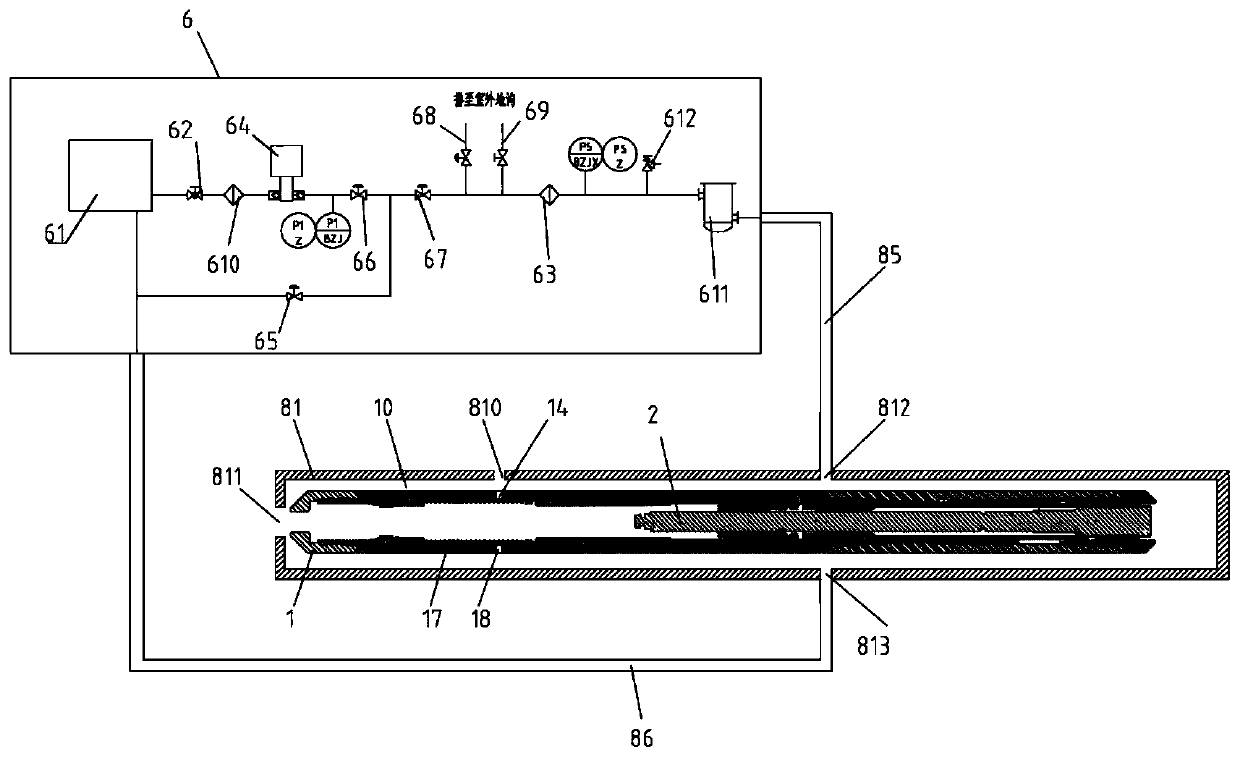

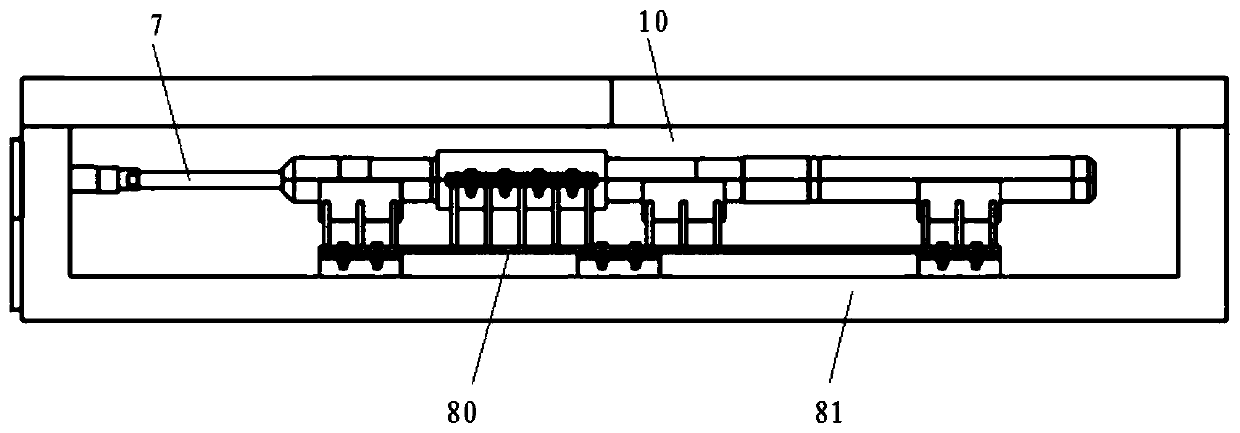

[0041] Such as figure 1 , 2 As shown, the oil-bath-based internal and external temperature-controlled fidelity corer experimental platform disclosed in the present invention includes a box body 81, an external heating system 6, and a pressure test chamber 10 for simulating the fidelity corer fidelity chamber. The pressure test chamber 10 is placed in a box body 81 , and the box body 81 is provided with a mount 80 , and the pressure test chamber 10 is fixed on the mount 80 . Casing body 81 can select explosion-proof box.

[0042] The tank body 81 is provided with a liquid inlet 812 , a liquid outlet 813 and a first reserved hole 810 for the test pipeline to pass through. The liquid inlet 812 and the liquid outlet 813 are disposed on opposite sides of the box body 81 .

[0043] External heating system 6 comprises liquid supply system and electric heater 611, and liquid supply system comprises oil tank 61 and pump 64, and the outlet of oil tank 61 links to each other with the ...

specific Embodiment approach 2

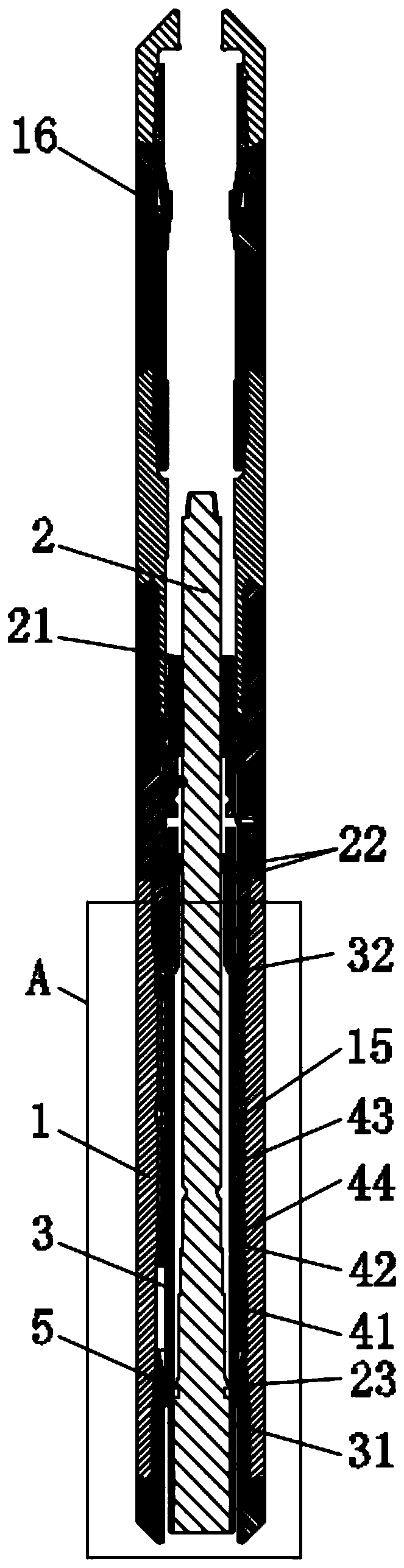

[0078] In this embodiment, the electric heating structure includes a graphene film. Specific as Figure 11 As shown, in order to facilitate the installation of the graphene film 21 , the electrical heating structure is produced by electroplating the graphene film 21 on the aluminum cylinder 20 . An annular groove 19 for installing the aluminum cylinder 20 is provided on the inner wall of the pressurized middle piece 13 , and the aluminum cylinder 20 electroplated with a graphene film 21 is embedded in the annular groove 19 on the inner wall of the pressurized middle piece 13 . The depth of the annular groove 19 is set according to the thickness of the aluminum cylinder 20, for example, the depth of the annular groove 19 and the wall thickness of the aluminum cylinder 20 are both set to 3mm.

[0079] It should be noted that the installation position of the aluminum cylinder 20 should avoid the liquid injection hole 14 or open a hole at the position of the aluminum cylinder 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com