Plastic pipe sealing performance experiment device

A technology of plastic pipes and experimental devices, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc. It can solve the problems of overshoot pressure, low degree of automation, and inaccurate experimental results, etc. Achieve the effects of improving pressure output accuracy, constant and accurate input pressure, and high accuracy of test parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

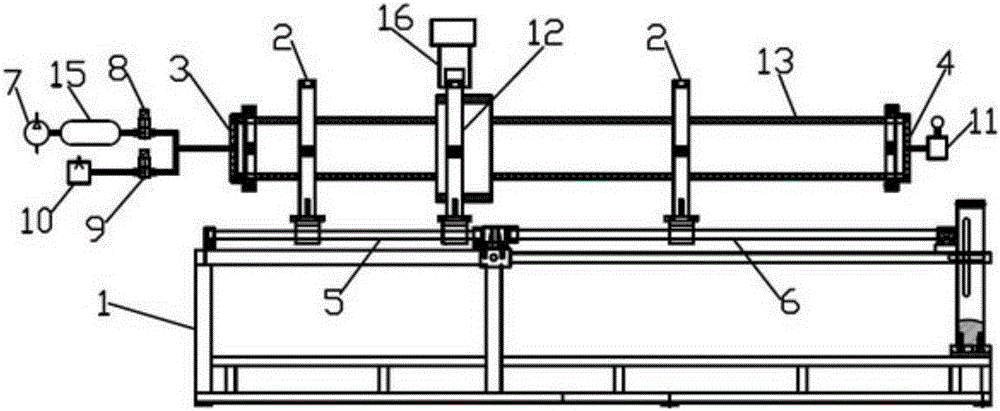

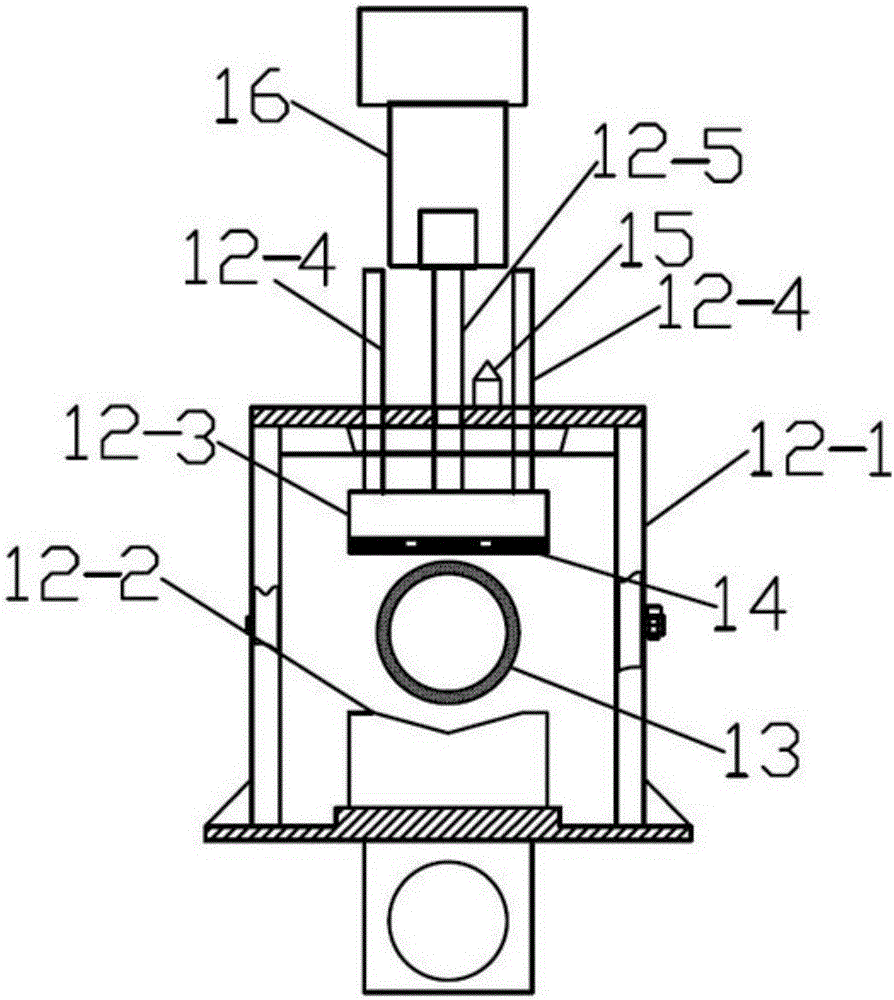

[0015] Depend on Figure 1-2 As can be seen from the shown embodiment, the present embodiment includes a test bench 1, on which a fixture fixing shaft is arranged, and a pipe fixture 2 for fixing the tube to be measured and a pipe fixture 2 for sealing the tube to be tested are installed on the fixture fixing shaft. The first port sealing jig 3 and the second port sealing jig 4 at both ends of the measuring tube are provided with plastic pipe pressure test connecting ports, and the jigs are fixed The shaft includes a first pipe clamp fixed shaft 5 and a second pipe clamp fixed shaft 6 with the same axis line, a buffer gap is provided between the first pipe clamp fixed shaft 5 and the second pipe clamp fixed shaft 6, The second pipe fixture fixed shaft 6 is provided with an axial displacement device (axially displaced by screwing in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com