Rotary experiment platform for fidelity coring device

The technology of an experimental platform and coring device, which is applied in the direction of instruments, undisturbed core extraction devices, and measurement, can solve the problems that the pressure test chamber cannot meet the needs, and achieve the effects of authentic test results, improved accuracy, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

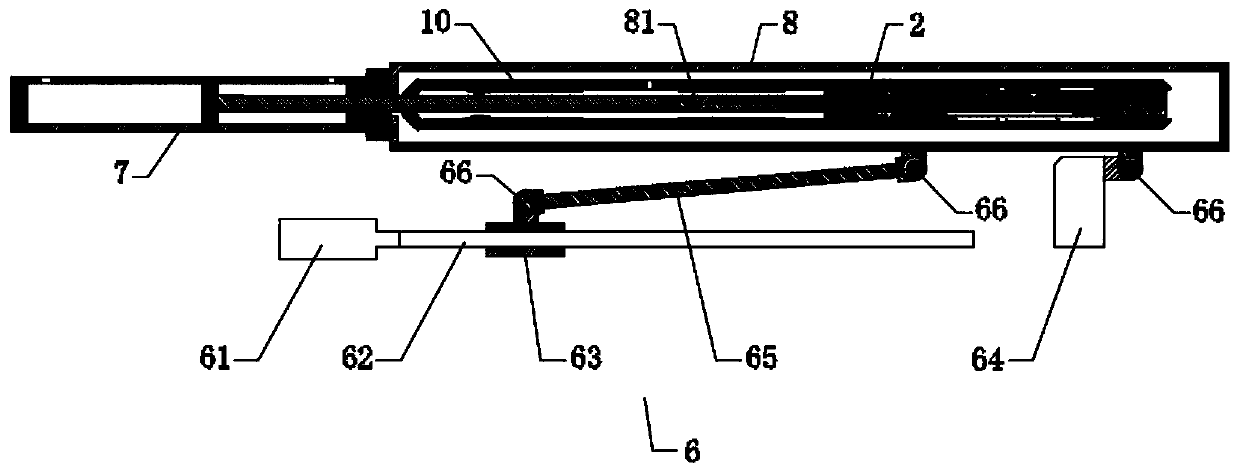

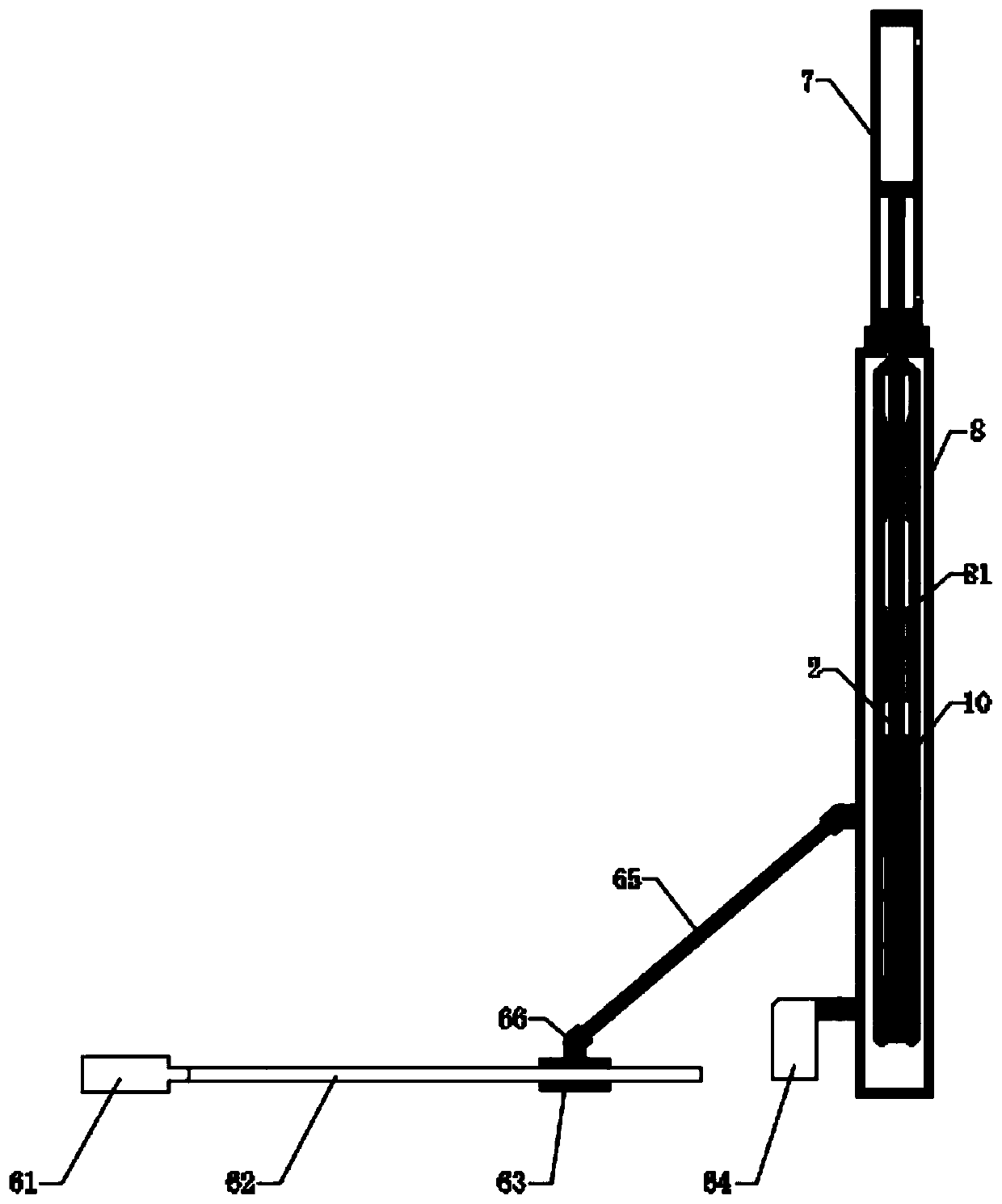

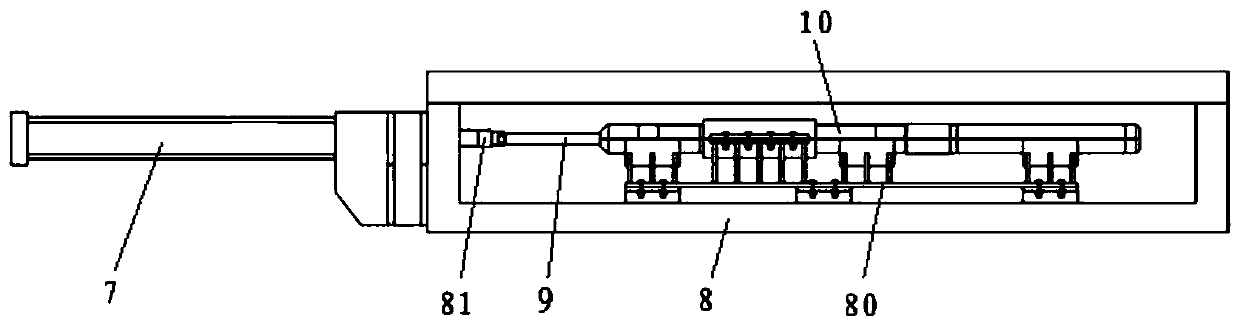

[0034] like figure 1 , 2 , 3, the rotary fidelity corer experimental platform disclosed by the present invention includes a casing 8, a pressure test cabin 10 for simulating the fidelity corer fidelity cabin, and the casing 8 can be horizontally A rotary drive mechanism 6 and a linear drive mechanism 7 that rotate from the vertical state to the vertical state or from the vertical state to the horizontal state. The pressure test cabin 10 includes a cabin body and a central rod 2 . The box body 8 is an explosion-proof box, and a mounting seat 80 is arranged in the box body 8, and the cabin body is fixed on the mounting seat 80.

[0035] The rotary driving mechanism 6 includes a motor 61 , a transmission mechanism, a movable block, a support arm 65 and a support 64 , and the bottom end of the box body 8 is movably connected with the support 64 .

[0036] The transmission mechanism converts the rotational motion of the motor 61 into the linear motion of the movable block 63 , o...

Embodiment approach 1

[0057] In Embodiment 1, the pressure-holding experimental cabin is connected to the hydraulic pipeline by drilling holes in the cylinder wall. The drilling of the drilling rig will damage the pressure-holding experimental cabin, thereby making the experimental results untrue.

[0058] like Figure 8 , 9 , 10, the cabin body in the present embodiment comprises a first experimental piece 11, a second experimental piece 12 and an intermediate connector 13, the first experimental piece 11 is the upper end of the outer cylinder 1 of the pressure-holding experimental cabin, and the second experimental piece 12 It is the lower end of the outer cylinder 1 of the pressure-holding experimental cabin, and the intermediate connecting piece 13 is a cylindrical structure; the first experimental piece 11 and the second experimental piece 12 are connected through the intermediate connecting piece 13, and the liquid injection hole 14 is arranged on the cylinder of the intermediate connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com