Insulating material electric resistance experiment plate electrode device for providing dynamic pressure and insulating material electric resistance experiment method

A technology of insulating materials and flat electrodes, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as aging of rubber materials, difficulty in installing cable accessories, and affecting the electrical resistance of the interface, so as to avoid friction and ensure smoothness and accuracy, the effect of guaranteeing accuracy and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

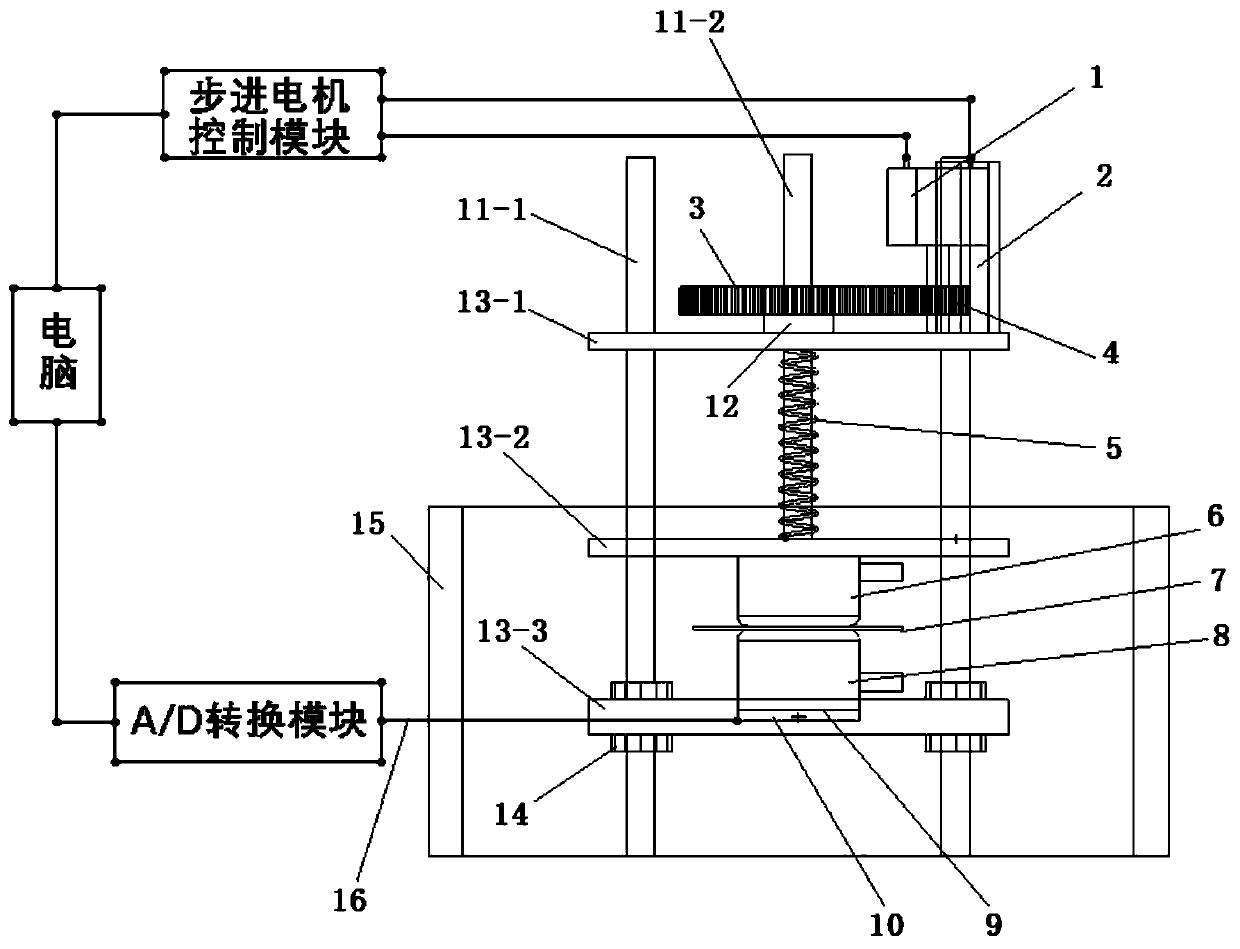

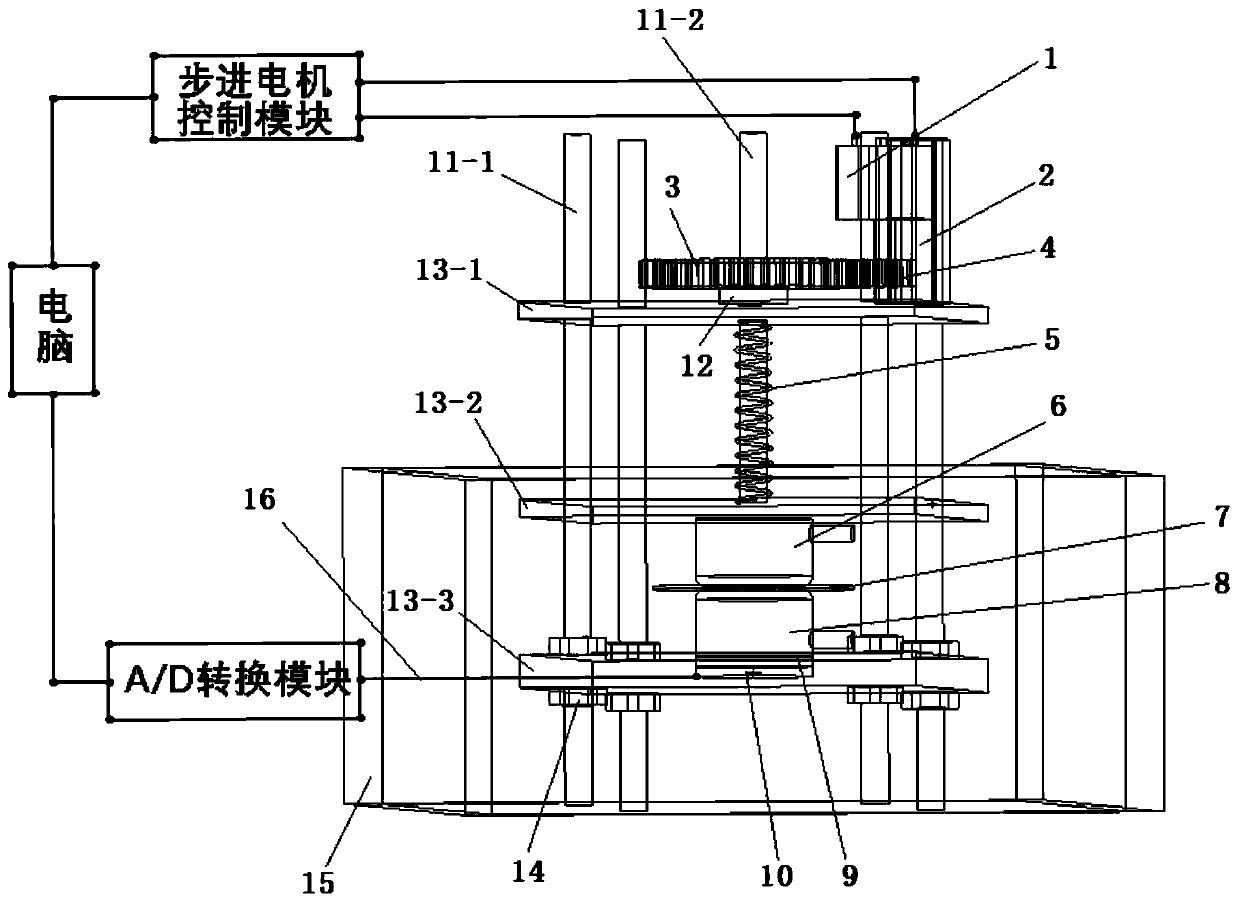

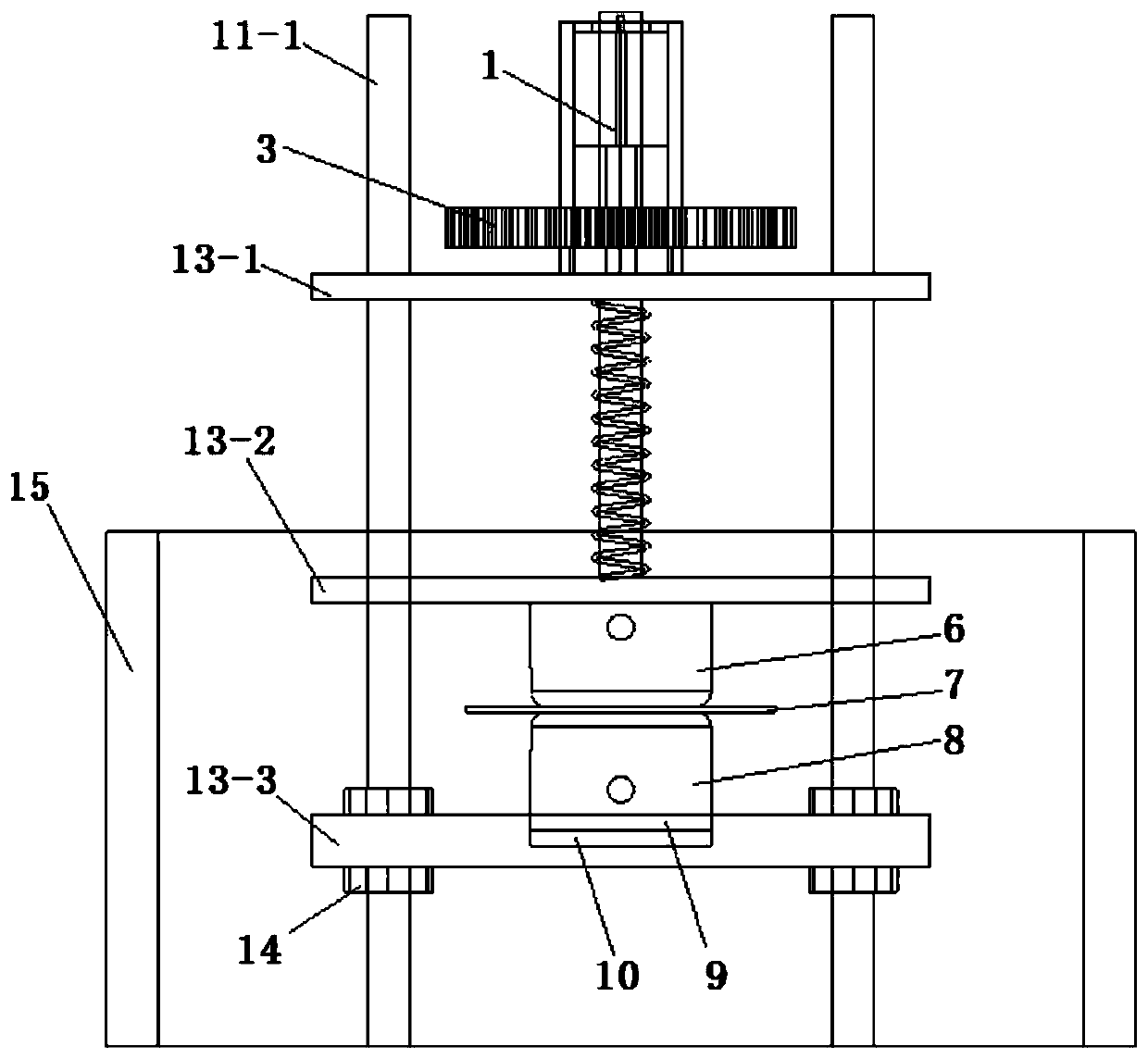

[0047] Example 1: Combining Figure 1-Figure 4 , a flat plate electrode device for an insulating material electric resistance experiment that provides dynamic pressure in this embodiment includes a stepping motor 1, a fixed bracket 2, a large gear 3, a small gear 4, a spring, a ground electrode 6, a polymer sample 7, High voltage pole 8, insulating gasket 9, piezoelectric sensor 10, multiple auxiliary support guide rods 11-1, main support guide rod 11-2, bearing 12, upper epoxy board 13-1, middle epoxy board 13-2 , lower epoxy plate 13-3, hex nut 14, oil tank 15, signal transmission line 16, A / D conversion module, computer and stepper motor control module; Described auxiliary support guide rod 11-1 and main support guide rod 11- 2 all adopt stainless steel screw rods; the insulating gasket 9 adopts a silicon rubber gasket; the piezoelectric sensor 10 is a thin film piezoelectric sensor;

[0048] The lower ends of the plurality of auxiliary support guide rods 11-1 are fixedly ...

Embodiment 2

[0054] Example 2: Combining Figure 1-Figure 4 , for an insulating material electric resistance test method that provides dynamic pressure in this embodiment, the method is realized by relying on the flat plate electrode device for insulating material electric resistance test described in Example 1.

[0055] Taking the breakdown experiment of a polymer insulation sample under a fixed pressure as an example, the specific operation steps are as follows:

[0056] Step 1, add simethicone oil into the oil tank 15, just cover the upper surface of the ground electrode 6, place the prepared circular polymer sample 7 with a thickness of 50 μm between the ground electrode 6 and the high voltage pole 8, and connect After wiring, turn on the computer control terminal and start the communication;

[0057] Step 2: Input the preset pressure of the sample at the computer control terminal, and control the stepping motor 1 rotor to drive the small gear 4 to rotate through the stepping motor co...

Embodiment 3

[0061] Example 3: Binding Figure 1-Figure 4 , for an insulating material electric resistance test method that provides dynamic pressure in this embodiment, the method is realized by relying on the flat plate electrode device for insulating material electric resistance test described in Example 1.

[0062] Taking the electrical aging experiment of polymer insulation samples under dynamic pressure as an example, the specific operation steps are as follows:

[0063] Step 1, add simethicone oil into the oil tank 15, cover the upper surface of the ground electrode 6, place the prepared polymer sample 7 between the ground electrode 6 and the high voltage pole 8, connect the control and feedback loop, and open Computer control terminal, start communication;

[0064] Step 2: Set the periodic change law of the pressure of the polymer sample 7 on the computer control end, each cycle is defined as two stages of boosting and depressurizing, and the boosting process increases from 0 MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com