Simulation physical model capable of visualizing different fracture network forms and manufacturing method

A technology of physical models and manufacturing methods, applied in teaching models, instruments, educational tools, etc., can solve problems such as pressure resistance, complicated manufacturing methods, and inability to meet the needs of oilfield development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

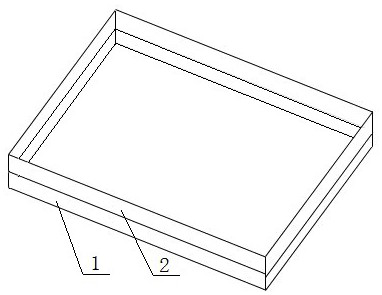

[0055] This embodiment relates to the simulation physical model of visualizing different slit network forms, such as figure 1 As shown, it includes an etched glass mother plate 1 and a smooth glass attached plate 2. The two plates are square and bonded to each other to form a cube. An injection port and an extraction port are set on the body of the smooth glass attached plate 2. The injection port and the The extraction outlets are all connected to the embedded nanoscale pore network structure of the etched glass mother plate 1, and the pore network structure at least includes different slit network shapes.

[0056] Both ends of the pore network structure are connected to the injection port and the production port through common pore throats.

[0057] Etched mother glass 1 is produced by dry etching, specifically:

[0058] A higher silicon dioxide etching rate is obtained by adjusting macroscopic parameters such as source gas flow ratio, radio frequency source power and self-...

no. 2 approach

[0072] This embodiment provides a method for making a simulated physical model that visualizes different slit network shapes, including:

[0073] Obtaining a target cast body thin section, where the target cast body thin slice is a stratum sample obtained from a target reservoir;

[0074] Extract target reservoir parameters from target cast thin slices;

[0075] Draw the pore network structure with different fracture network shapes according to the target reservoir parameters;

[0076] Etching the pore network structure on the material layer of the glass sheet by using a photolithographic mask to obtain a mother glass plate;

[0077] Dry etching the mother glass to obtain the etched mother glass 1;

[0078] Take the smooth glass attached plate 2 and place it under the etched glass mother plate 1, and bond the two plates together;

[0079] Two plates are processed to obtain a simulated physical model that visualizes different seam network morphologies.

[0080] Get target c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com