Real three shaft pressure box

A pressure box, true triaxial technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large frictional force, complex structure, poor versatility and applicability, etc. Reliable and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

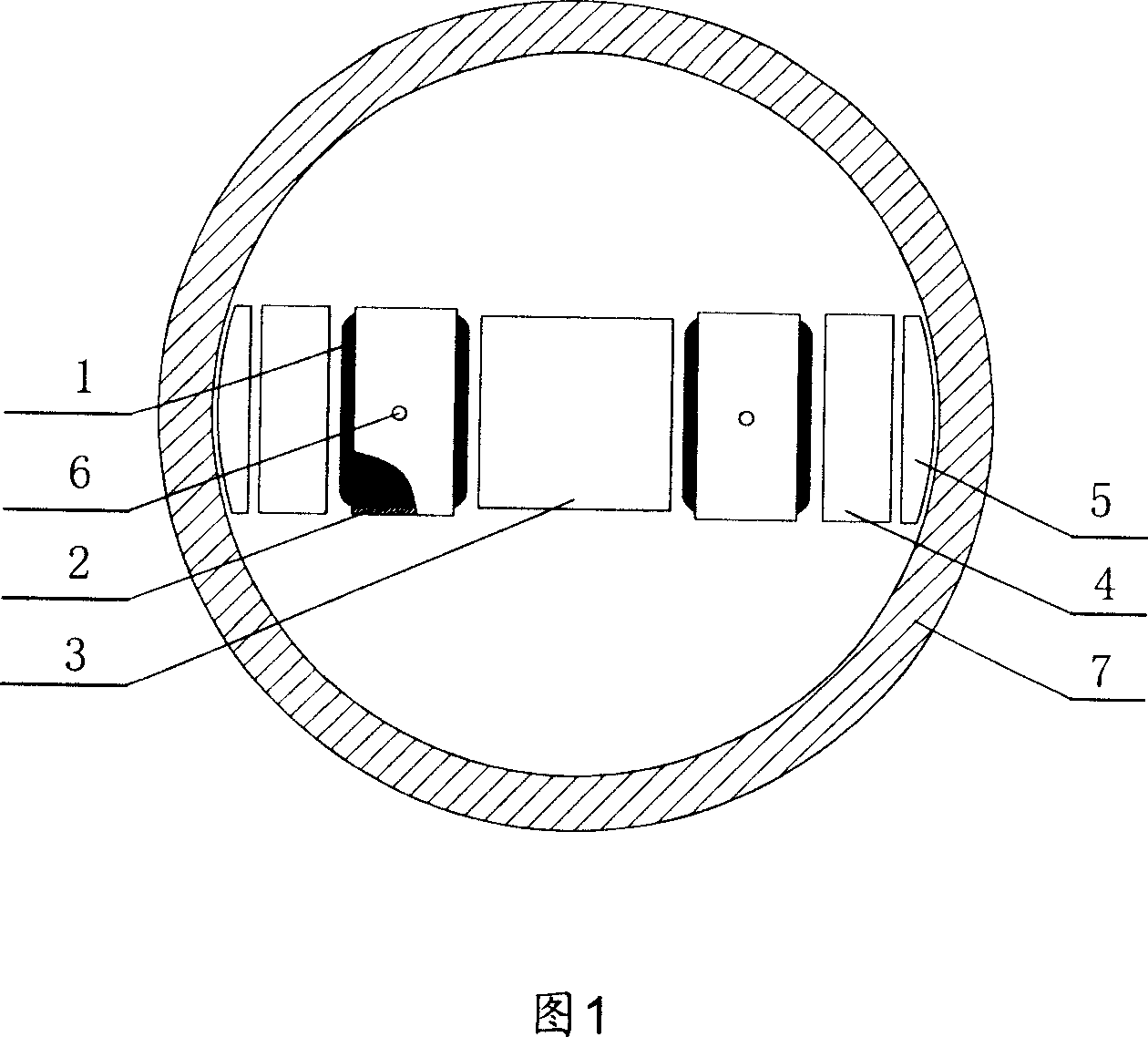

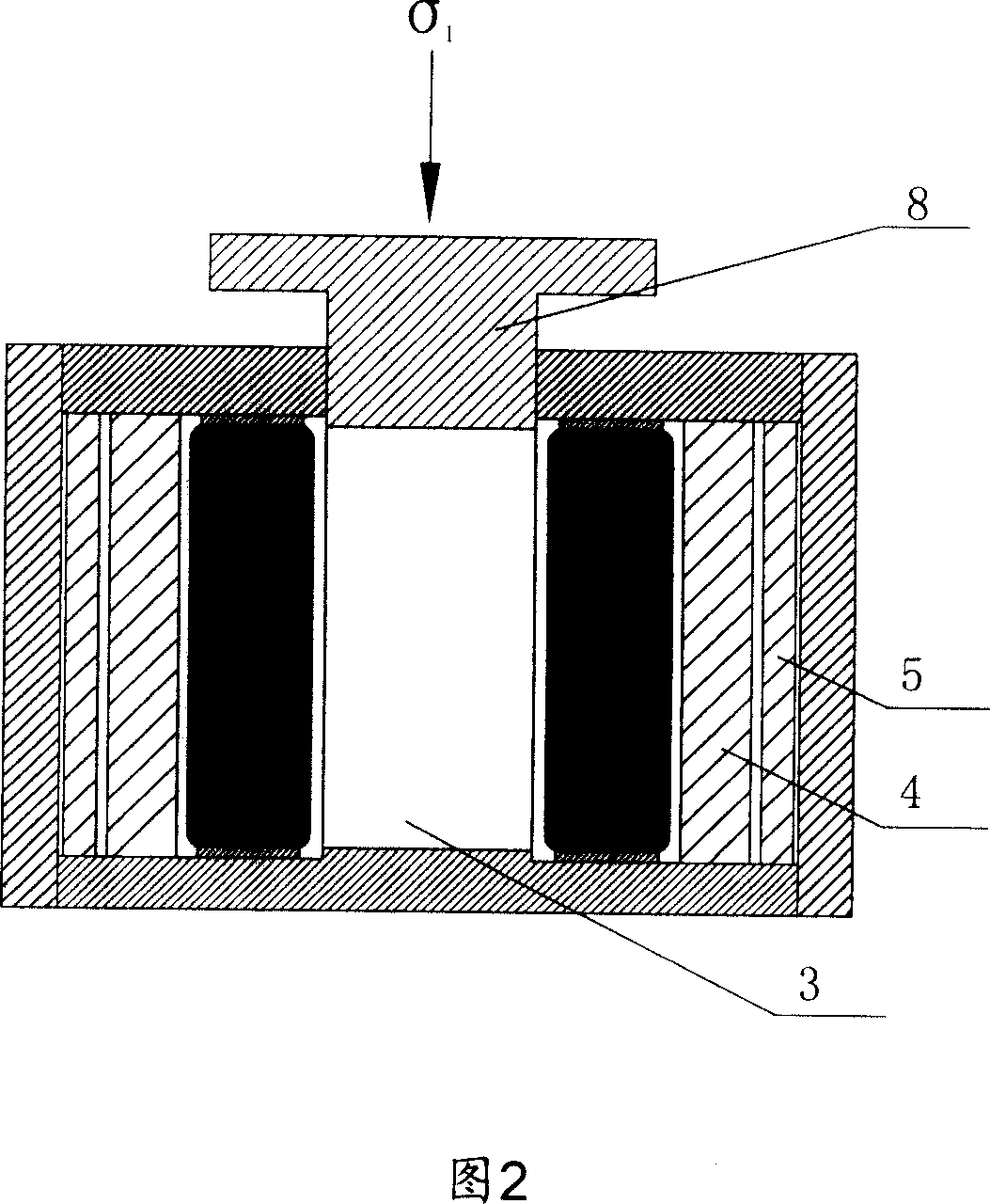

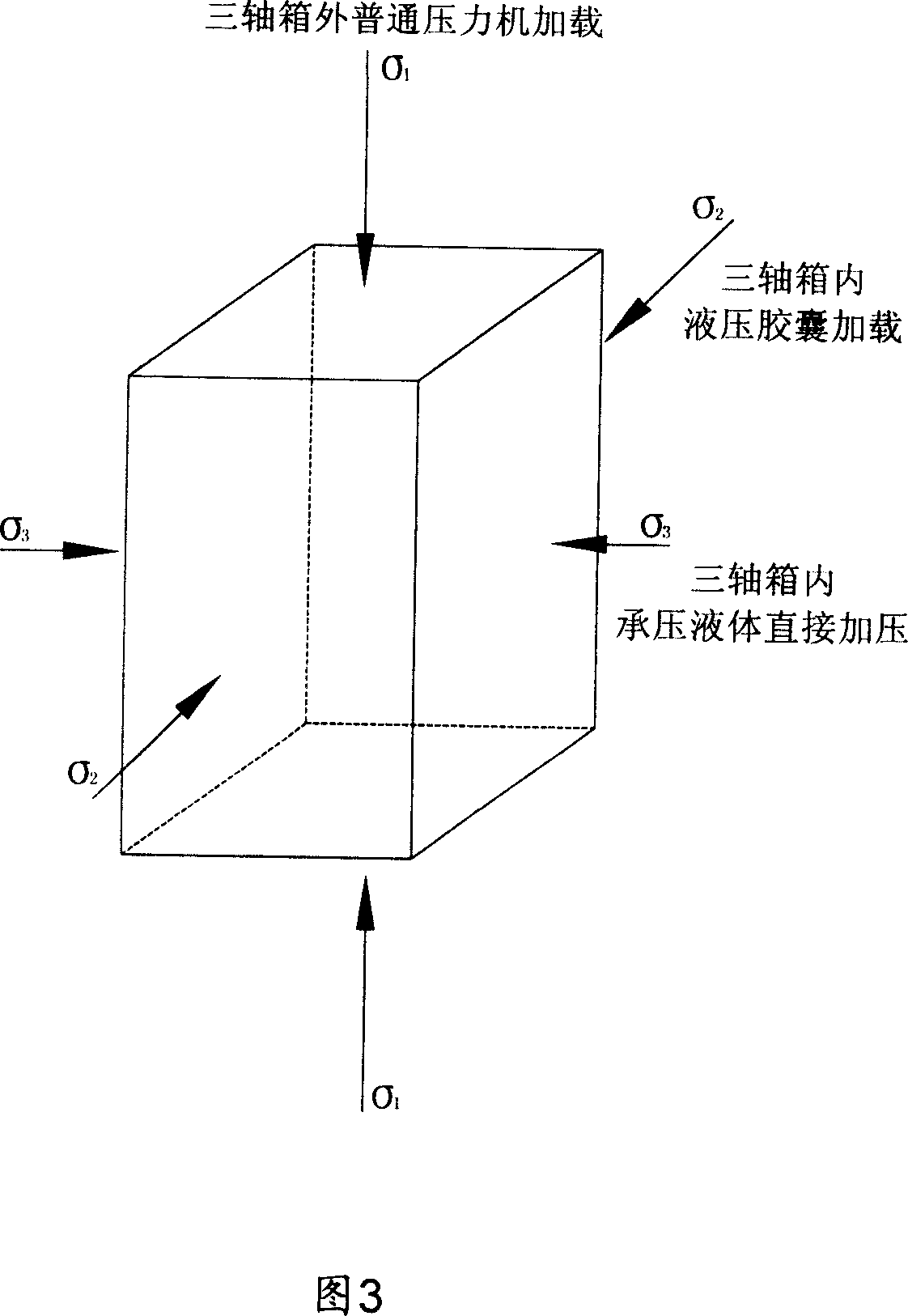

[0025] The true triaxial pressure box of the present invention is used to provide three unequal triaxial pressures for the test piece. The test piece used is a rectangular parallelepiped. The preferred embodiment is shown in Figure 1 and Figure 2 and includes a closed cylinder. Body 7, the test piece 3 is placed in the cylinder, and the cylinder 7 is provided with an external pressurizing device 8 that communicates with the outside and can slide relative to the cylinder 7 to provide axial pressure for the test piece 3. The maximum principal stress σ 1 , Σ 1 Generally, the external pressurizing device 8 can be pressurized by a press or other pressurizing device.

[0026] The cylinder 7 is provided with an intermediate principal stress σ for the test piece 3 2 The built-in pressurizing device adopts the built-in lateral pressurizing device, which can be made into a separate true triaxial pressure box. The structure of the true triaxial pressure box is simple and the pressure is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com