Loading tool system for axle pressure experiment of spaceflight cylindrical shell

An experiment and tooling technology, which is applied in the field of loading tooling system for aerospace cylinder shell axial compression experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The core idea of the present invention is to adopt a loading tooling system for the axial pressure test of the aerospace cylinder shell to realize the purpose of precise loading of the axial pressure load for the axial pressure test of the cylinder shell.

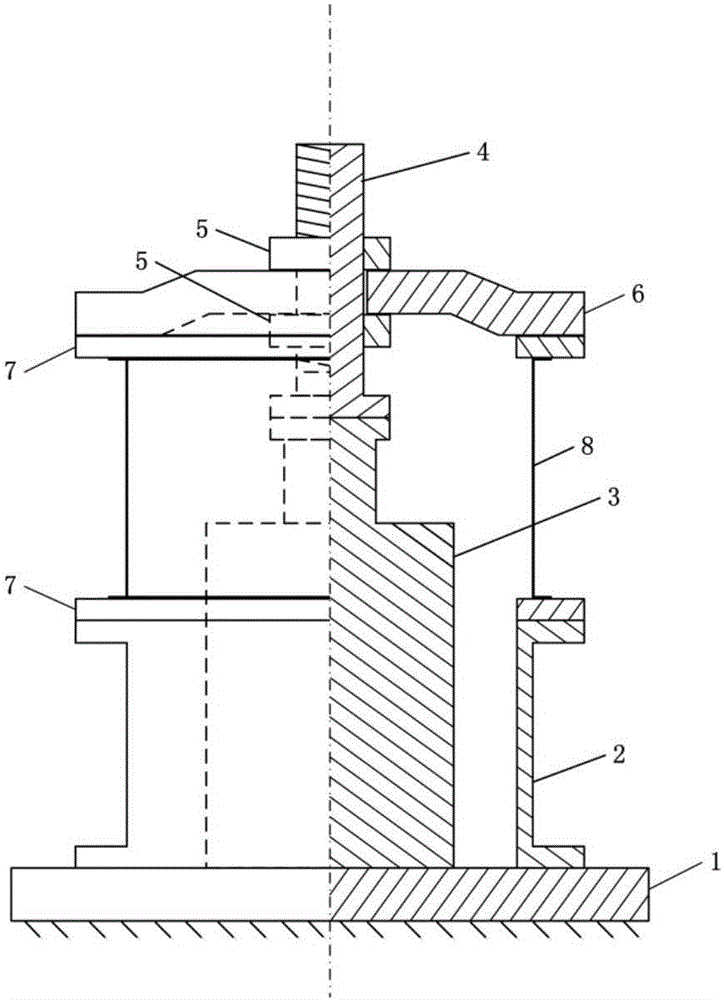

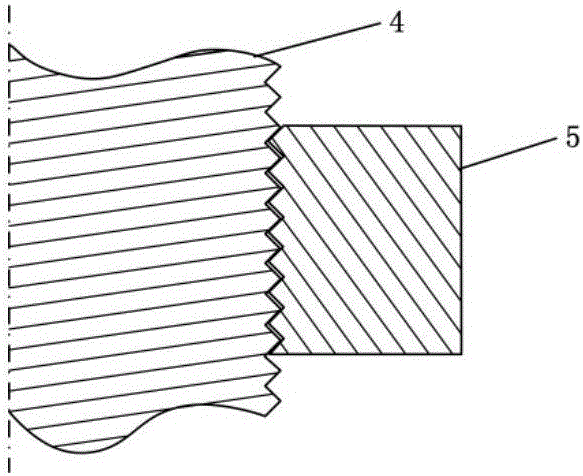

[0017] figure 2 It is a partial enlarged view of the joint between the radial force sensor or the limit block and the approximately rigid connecting column, refer to figure 1 , a loading tooling system for an aerospace cylinder shell axial compression experiment provided by the present invention mainly includes a tooling base 1, a tooling base adapter frame 2, a bidirectional actuator 3, an approximately rigid connecting column 4 with threads on the surface, and a radial force Sensor or limit block 5, loading cap 6, test adapter ring 7 and test piece 8.

[0018] The tooling base 1 is placed on a flat ground, and after the lower end surface of the bidirectional actuator 3 is connected to the tooling base 1 by high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com