Conducting medium for high-stress and large-deformation environment, assembly part and application thereof

A conductive medium and assembly technology, applied in the application field of high-voltage experiments, can solve problems such as failure to rise, circuit resistance changes, and assembly compression deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

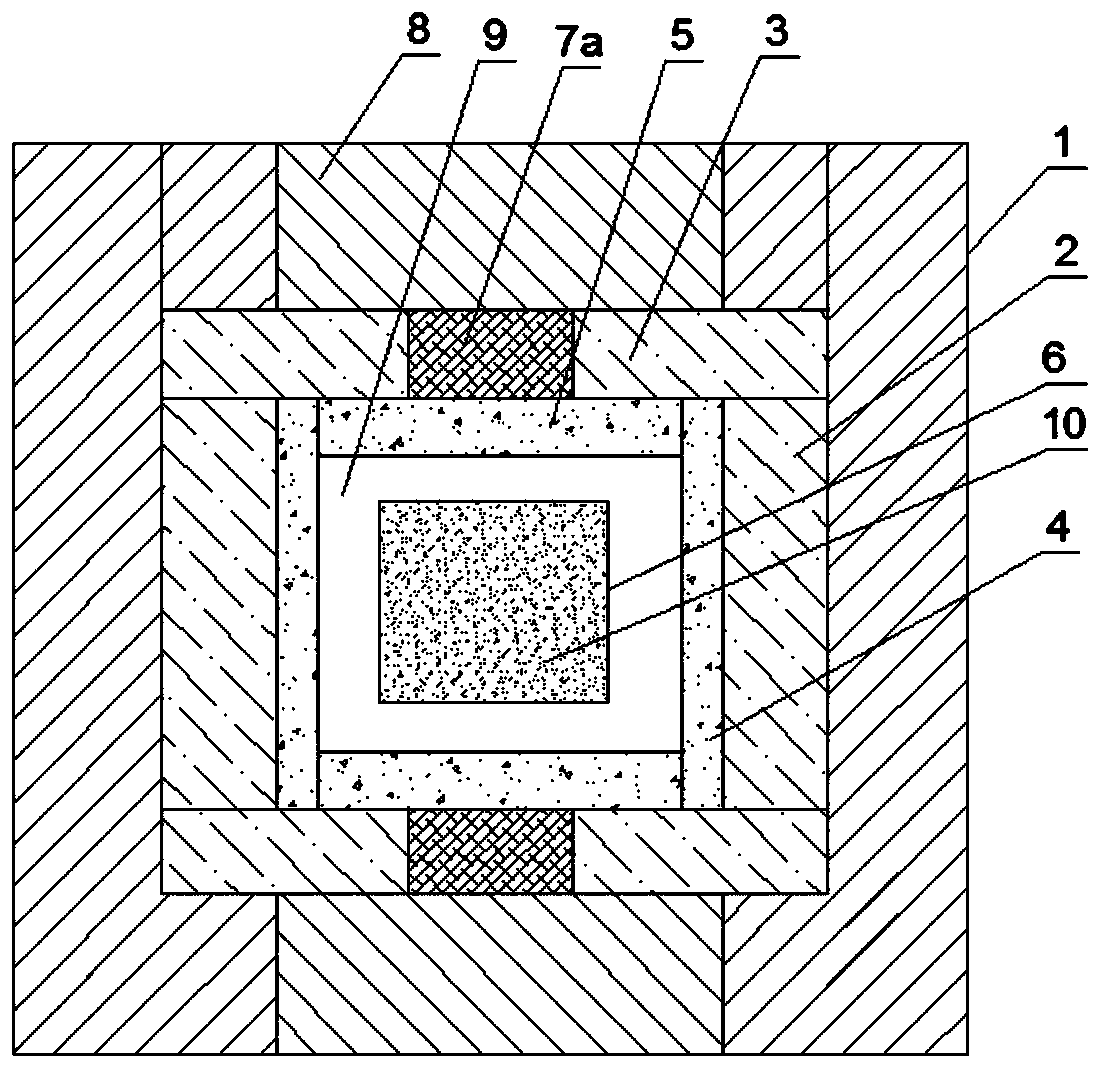

[0027] Such as figure 1As shown, this embodiment provides an assembly for high-pressure experiments, which is a first-level assembly adapted to a six-sided top press, including a phyllolith block 1, a dolomite tube 2, and a dolomite ring 3 , carbon tube 4, carbon sheet 5, molybdenum cup 6, the leaf stone block 1 is a square leaf stone block 1, a cylindrical cavity is arranged in the leaf stone block 1, and plugs are arranged at the upper and lower ends of the cavity To block the channel, the dolomite tube 2 is set in the cylindrical cavity of the phyllite, and two dolomite rings 3 are respectively set at the upper and lower ends of the dolomite tube 2 to enclose the pressure cavity, and the conductive channel is two The inner circle of a dolomite ring 3; the carbon tube 4 is arranged in the pressure chamber, and the two carbon sheets 5 are respectively arranged on the upper and lower ends of the carbon tube 4, and the carbon tube 4 and the carbon sheet 5 form a heating chamber...

Embodiment 2

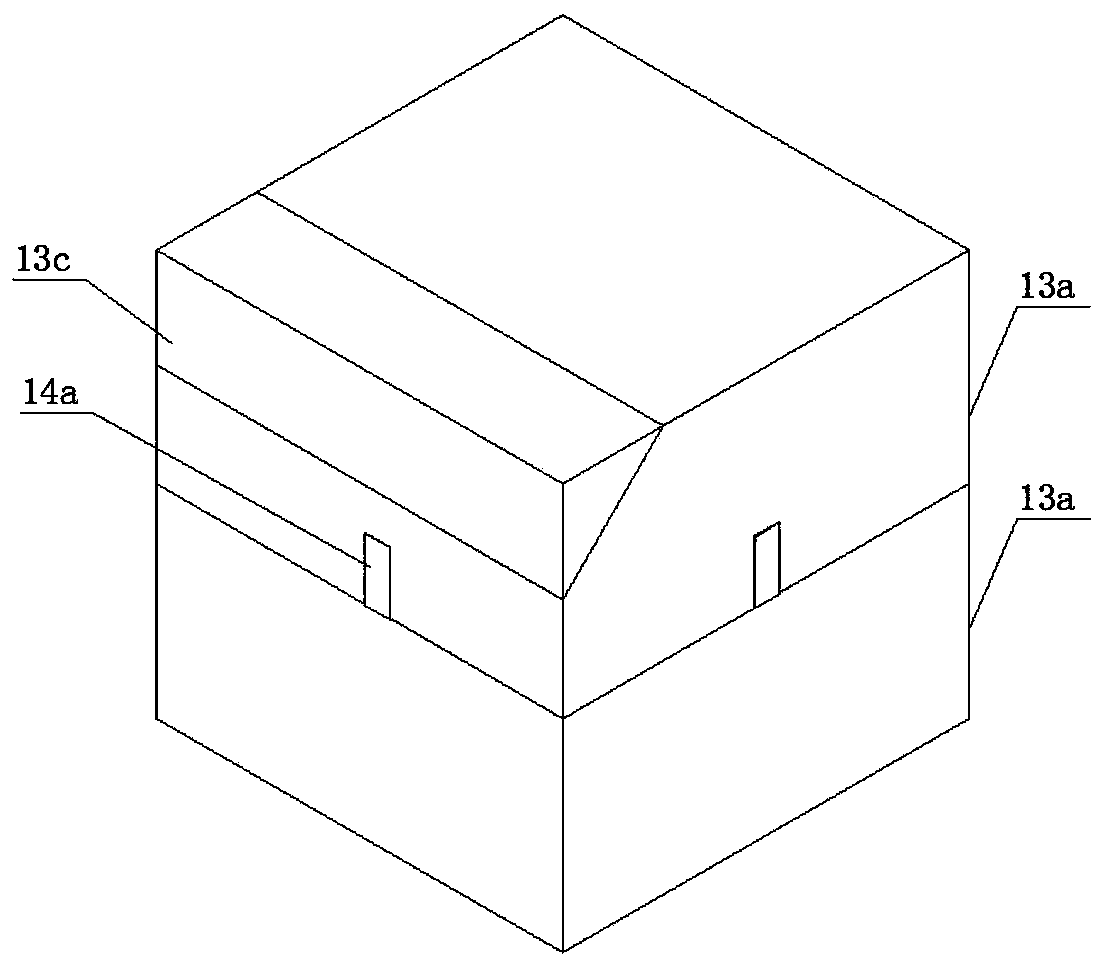

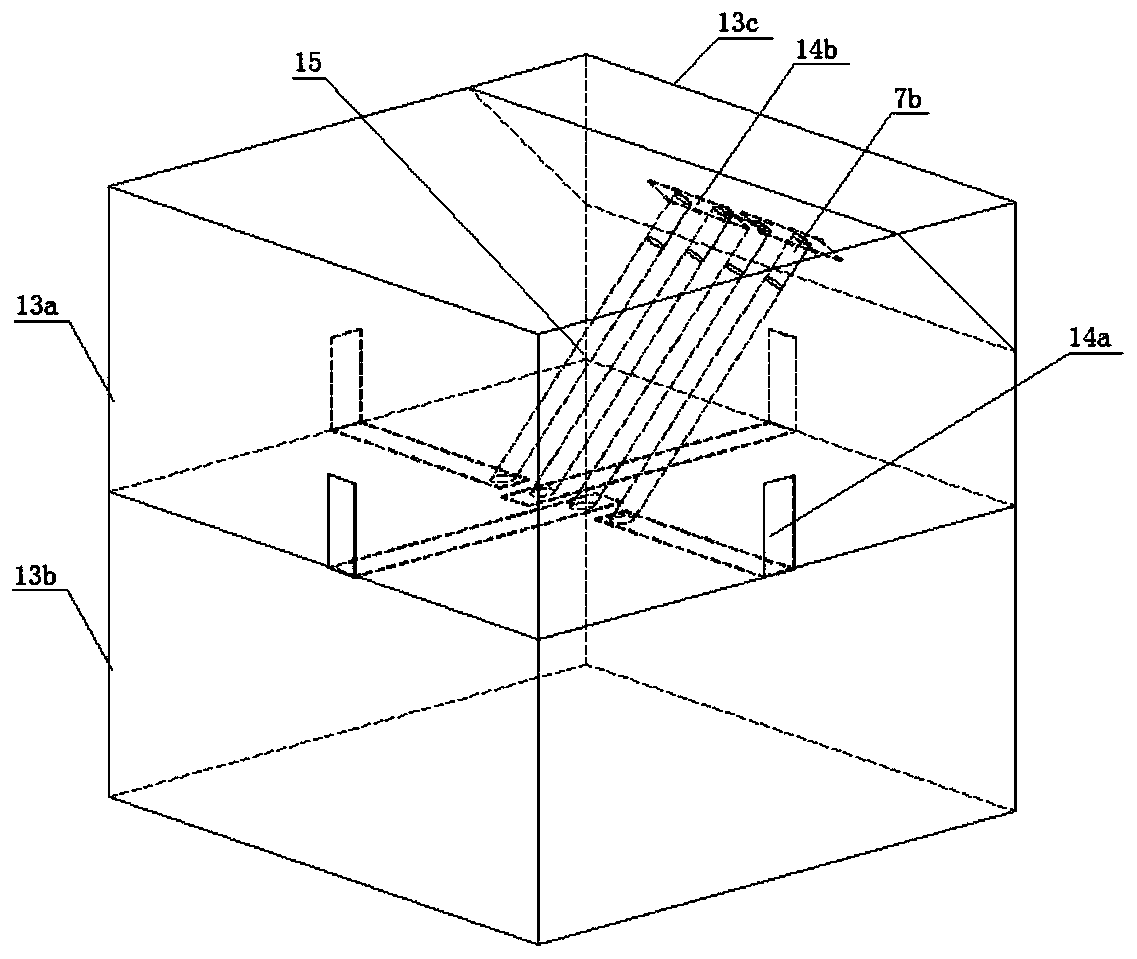

[0030] This embodiment provides a first-level standard pressure assembly of four-wire method, the purpose of which is to calibrate the sealing edge pressure of the first-level experiment. The principle is to calibrate the pressure achieved in the assembly by testing the resistance change of the standard pressure sample under high pressure. In this embodiment, the use of bismuth silk as the standard pressure material for standard pressure is taken as an example, such as Figures 2 to 4 As shown, the assembly adopts a square standard pressing block 13 made of phyllostone. The standard pressing block 13 is processed into upper and lower parts. Copper central conductive sheet 14a, one edge of the top of the superscript pressure block 13a is cut off, and the cut section is a triangular prism 13c, and four parallel conductive channels are drilled on the superscript pressure block 13a, and the four conductive channels are respectively formed by the edge The cut surface extends to a c...

Embodiment 3

[0034] This embodiment provides an assembly applied to an in-situ neutron diffraction device, such as Figure 5 , 6 As shown, the middle part of the sealing gasket 11 has a through hole through the sealing gasket 11 as the pressure cavity, the pyrolite ring 12 is arranged in the pressure cavity, and the grooves extending toward the sample chamber at the upper and lower ends of the sealing gasket 11 form a conductive cavity. Channel, the copper powder is pre-pressed under a pressure of 20MPa to form a conductive medium 7c suitable for the conductive channel, and the conductive medium 7c is installed in the conductive channel.

[0035] Taking the measurement of Bi (bismuth) sample electrical signal as an example, a constant current source is used to provide a constant current for the standard voltage circuit, and a multi-channel recorder is used to record the voltage change of the circuit. Because the upper and lower anvils of this device are electrically insulated from each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com