Method for measuring surface profile of honeycomb core

A measurement method and surface profile technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as unspecified methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

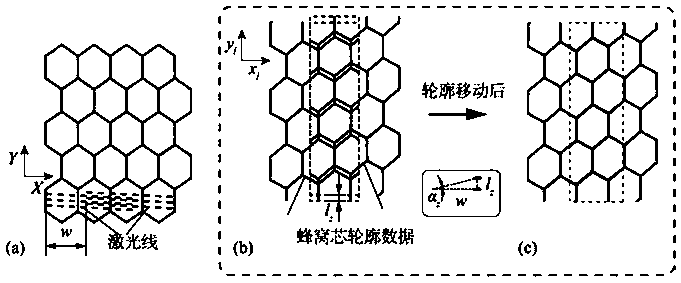

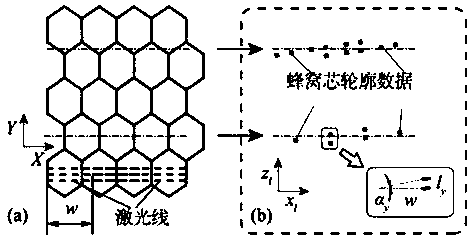

[0153] 1. Measurement platform construction

[0154] The laser displacement sensor selected in this embodiment is an ultra-high-speed profile measuring instrument (LJ-V7060) of Keyence Corporation. The measuring instrument adopts blue semiconductor laser, which can realize stable and ultra-high-speed measurement, the sampling interval can reach 16μs, the repeated measurement accuracy in the Z-axis direction can reach 0.4μm, the measurement contour data interval is 20μm, and the measured laser line length is 15mm. During the measurement, the probe of the profile measuring instrument is installed on the three-axis CNC machine tool, the standard part to be measured is fixed on the machine table, and the movement of the probe of the profile measuring instrument is controlled by the machine tool to scan the surface of the standard part.

[0155] The measured honeycomb core is a honeycomb core with hexagonal structural units.

[0156] 2. Installation error calibration of line laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com