Analog heat source chip and manufacturing method thereof

A heat source and chip technology, applied in the field of simulating heat source chips and their production, can solve the problems of complicated infrared thermal imaging test system equipment, difficult heat source chip temperature, high price, etc., to achieve high-power heating, simple structure, and measurement process. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

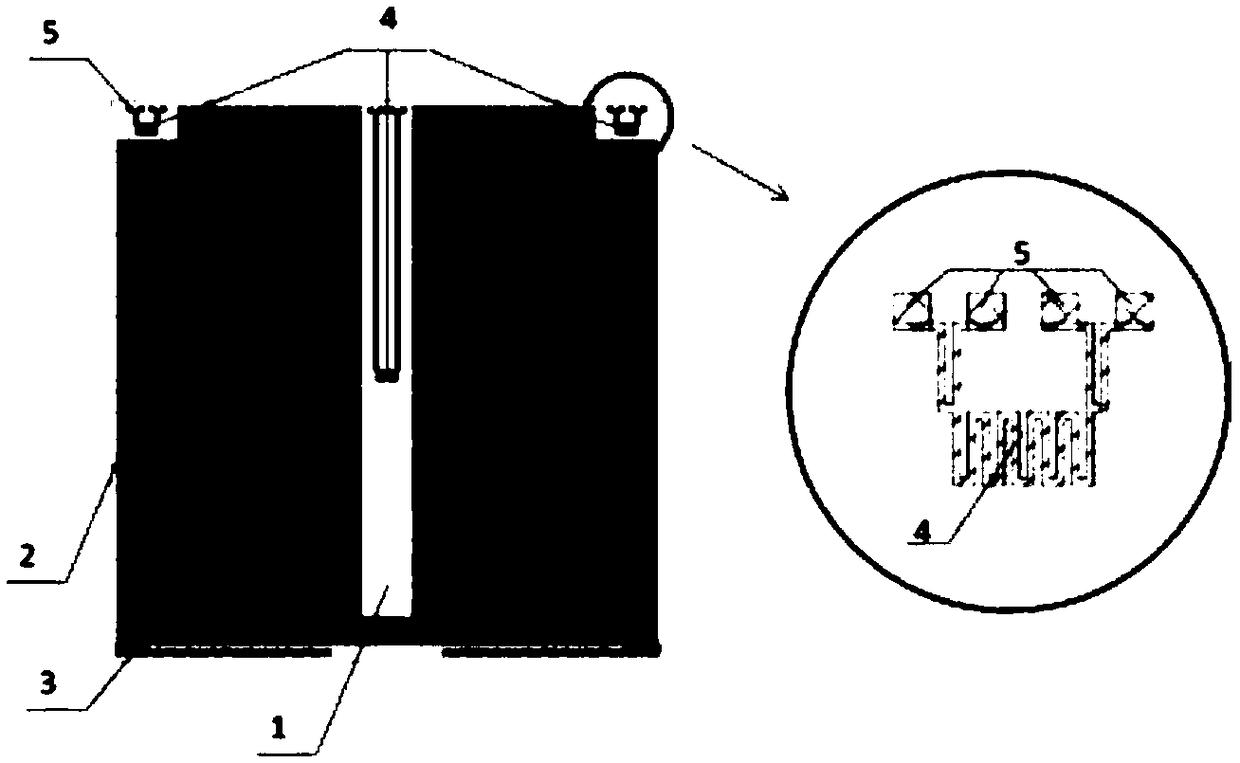

[0046] Such as Figure 1-3 As shown, an analog heat source chip 1 has an analog heat source resistor 2 and a temperature sensor 4 on its surface, and both the analog heat source resistor 2 and the temperature sensor 4 are thin film planar resistors.

[0047]The temperature coefficient of resistance of metal is linear, and the resistance change can be measured by the four-wire method to characterize the temperature change of the metal. This method is widely used in metal temperature sensors. In the above-mentioned technical scheme, the simulated heat source resistance 2 is evenly distributed on the surface of the entire simulated heat source chip 1 to realize uniform heat generation, and the temperature sensor 4 can be distributed at any position on the surface of the simulated heat source chip 1, and its actual distribution position is based on the thin film microchannel heat sink. The heat dissipation structure is determined. During the test, the simulated heat source chip 1...

Embodiment

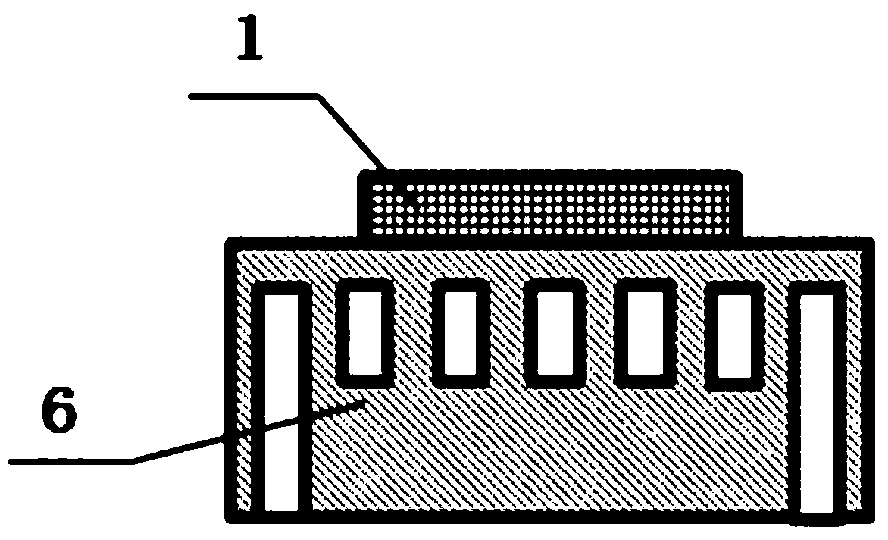

[0071] Such as Figure 1-3 As shown, a simulated heat source chip 1 includes a welding layer, a substrate, a passivation layer, an adhesion layer and a metal film layer, the welding layer is arranged on the lower surface of the substrate, and the passivation layer is arranged on the lower surface of the substrate. On the upper surface of the substrate, the adhesion layer is arranged on the surface of the passivation layer, and the metal film layer is arranged on the surface of the adhesion layer; the metal film layer is composed of an analog heat source resistance 2 and a temperature sensor 4, A heat source pad 3 and a sensor pad 5 are also provided on the metal film layer.

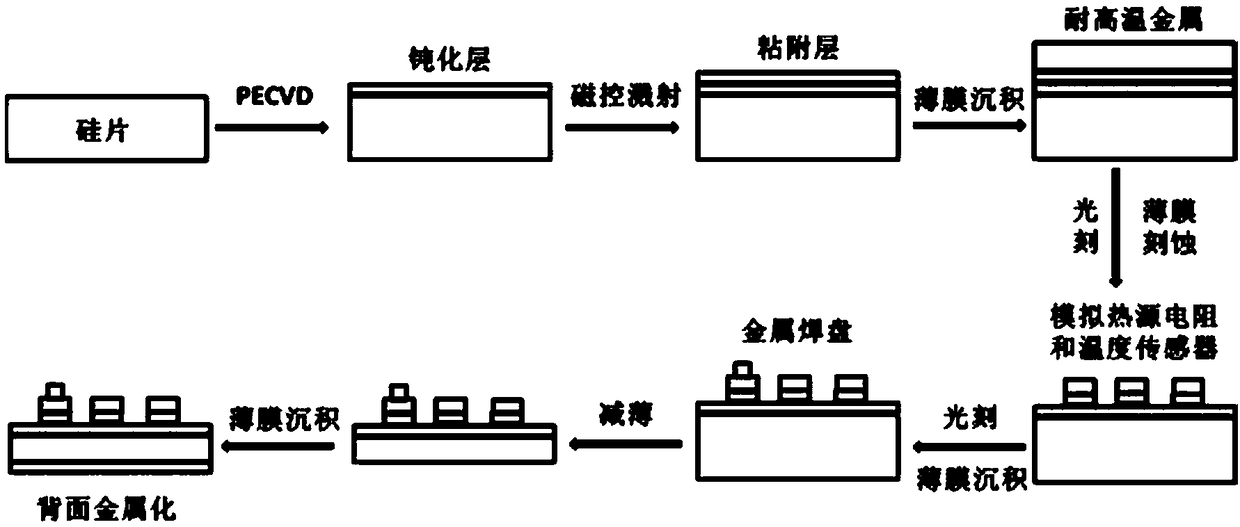

[0072] The material of the substrate is silicon, the material of the passivation layer is SiN, the material of the adhesion layer is TiN, the material of the soldering layer is Au, and the material of the metal film layer is W. The thickness of the substrate was 100 micrometers. The simulated heat sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com