An environmentally friendly and energy-saving hot blast stove capable of high-power heating and adjustable heating power

An environment-friendly, energy-saving, power-regulating system technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as coking, hot stoves cannot run stably for a long time, black fire, etc., and achieve improved burnout rate, Reasonable force and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the present application, the embodiments of the present application will be described in detail below with reference to the accompanying drawings. It should be noted that the features in the embodiments and embodiments in the present application may be any combination with each other in the case of an unable conflict.

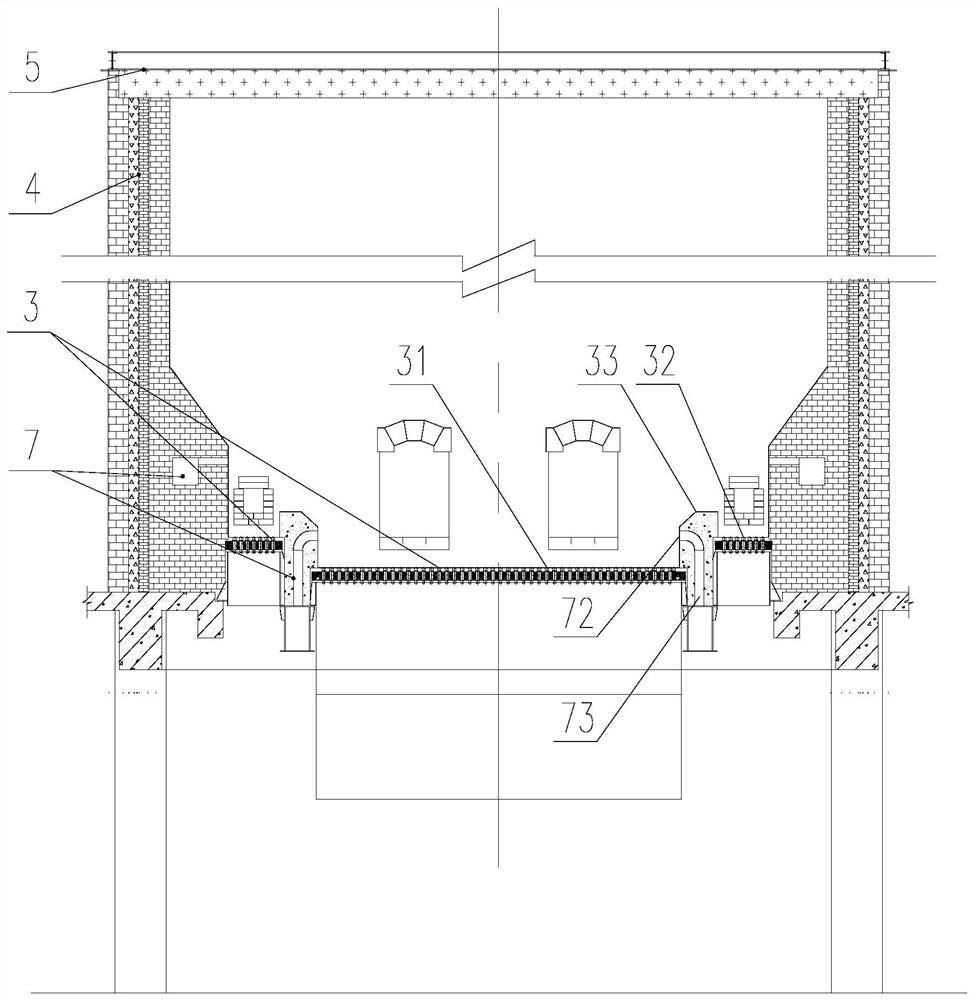

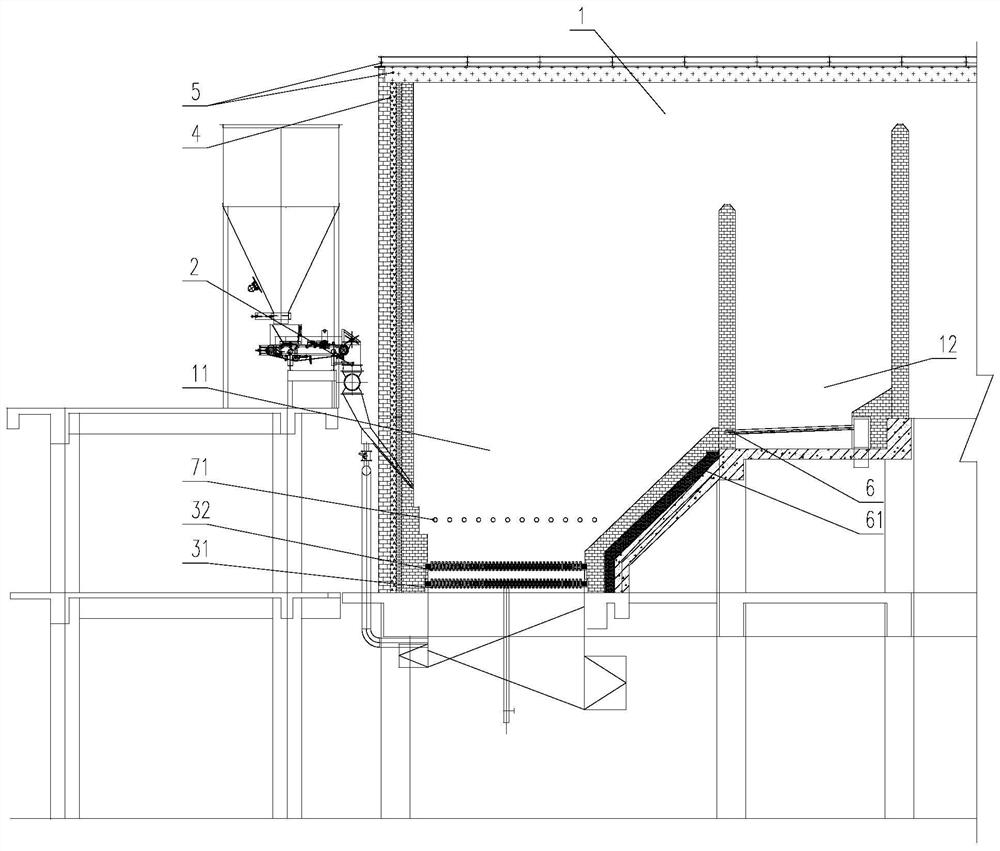

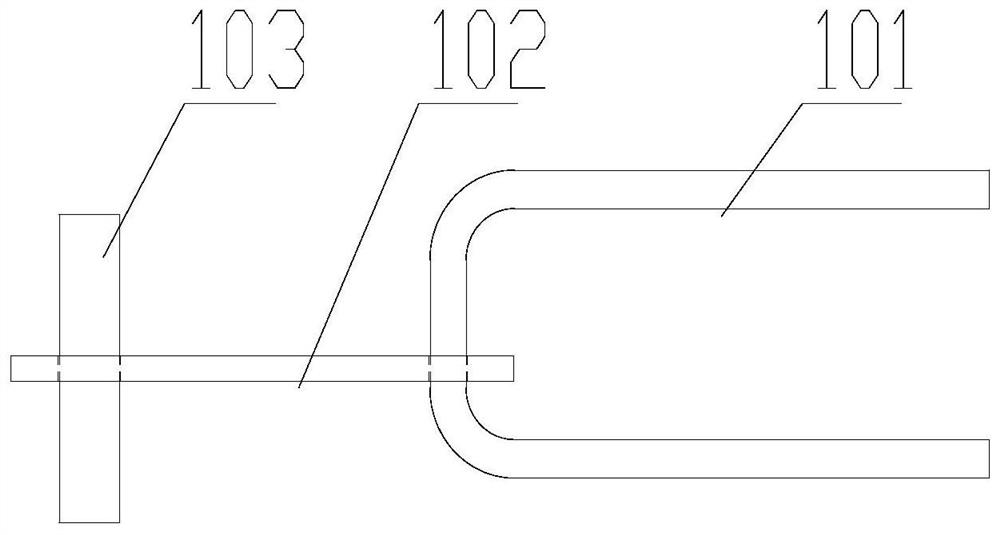

[0035] The embodiments of the present application provide an environmentally-friendly energy-saving hot air furnace that is capable of high power heating and heating power, such as figure 1 with figure 2 As shown, comprising: a furnace body 1, a baking coal system 2, a main parallel bed power conditioning system 3, a composite furnace wall system 4, a lightweight flank and a light steel structural system 5.

[0036] The furnace body 1 includes a furnace 11 and a settling chamber 12, the lower portion of the settling chamber 12, and the upper portion is connected, and the lower portion is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com