A method of making a magnetic conduction heating element with an all-glass container

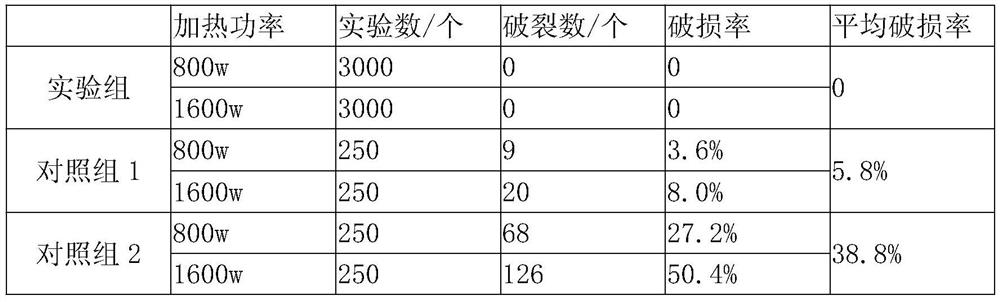

An all-glass, heating element technology, applied to the structure of cooking utensils, cooking utensils, special materials for cooking utensils, etc., can solve the problems of not exceeding 400W, easy to break, and long heating time of liquids, etc., to achieve short heating time and market prospects wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023]This example discloses a method of making a magnetizing heating body with a full glass vessel, including the following steps:

[0024]Step 1, choose the full glassware: all-glassware according to the production needs;

[0025]Step 2, cleaning drying: Clean all glassware, dry after drying;

[0026]Step 3, all-glassware pretreatment: Put the dry full glassware into the oven to heat up to 700 ° C, and constantly stock;

[0027]Step 4, full glassware wire printing magnetic material: Magnetic material wire printing in the bottom of the entire glassware required for magnetically heat;

[0028]Step 5, inert gas cooling treatment: cooling the inert gas to -35 ° C for use by liquid nitrogen;

[0029]Step 6, quenching: Put the full glassware after the wire in step four is placed in a high temperature furnace to heat up to 700 ° C and the constant temperature is maintained from 1 to 2 h, and then the inert gas in the step 5 is uniformly blown on this full glassware. It has caused it to cool down to 65 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com