A reinforced composite material sleeper for rail transit and its production process

A reinforced composite material and rail transit technology, applied in the field of reinforced composite sleepers for rail transit and its production technology, can solve the problems of complex sleeper manufacturing process, high product cost, and difficulty in popularization and use, so as to meet the railway use conditions and reduce the Effects of maintenance and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

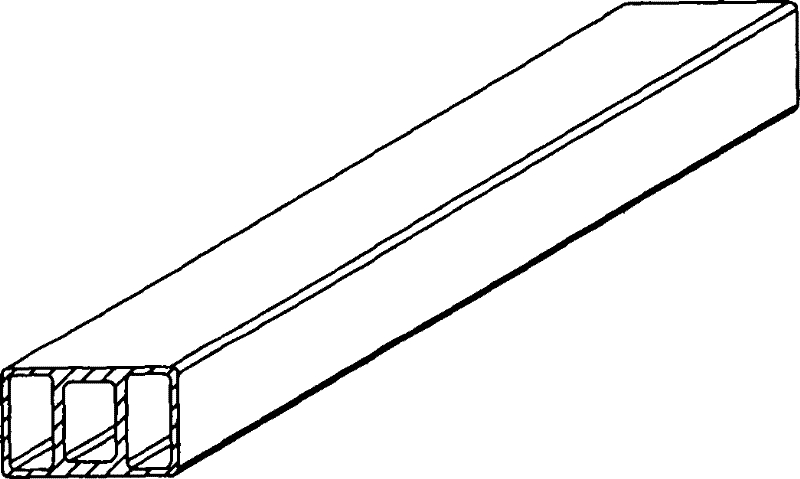

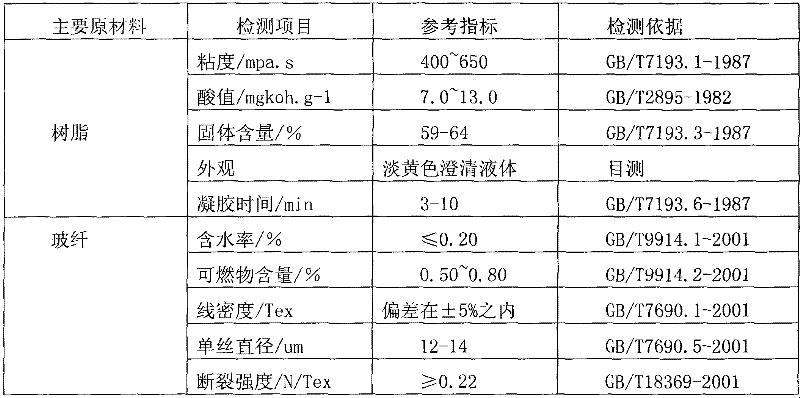

[0023] Refer to attached figure 1 and figure 2 , the present invention is a reinforced composite material sleeper for rail transit, the sleeper includes a sleeper body and high-density polyurethane foam filled in the sleeper body; the sleeper body is made of the following raw materials in parts by weight: unsaturated polystyrene 90 parts of ester resin, 1 part of initiator, 1 part of liquid release oil, 40 parts of filler, 1 part of viscosity reducer, 1 part of auxiliary agent, 170 parts of a mixture of glass fiber felt and glass fiber multiaxial cloth; The ratio of glass fiber, glass fiber mat and glass fiber multiaxial cloth is 60:10:30. Its filler is hollow glass microspheres. Its auxiliary agent is a silane coupling agent.

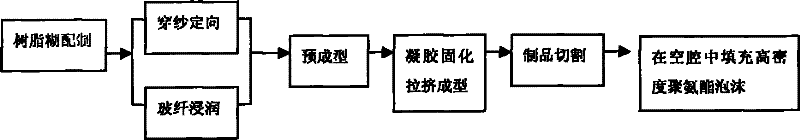

[0024] A production process for reinforced composite material sleepers for rail transit, comprising the following steps:

[0025] (1) According to the proportion of the formula, the unsaturated polyester resin and other ingredients are stirred eve...

Embodiment 2

[0033] Refer to attached figure 1 and figure 2 , the present invention is a reinforced composite material sleeper for rail transit, the sleeper includes a sleeper body and high-density polyurethane foam filled in the sleeper body; the sleeper body is made of the following raw materials in parts by weight: unsaturated polystyrene 80 parts of ester resin, 2 parts of initiator, 2 parts of liquid release oil, 30 parts of filler, 2 parts of viscosity reducer, 1-3 parts of auxiliary agent, mixture of glass fiber, glass fiber mat and glass fiber multi-axial cloth 150 part; the proportioning of glass fiber, glass fiber felt and glass fiber multiaxial cloth in the mixture is 60:10:30. Its filler is aluminum oxide, and its auxiliary agent is silane coupling agent.

[0034] A production process for reinforced composite material sleepers for rail transit, comprising the following steps:

[0035] (1) According to the proportion of the formula, the unsaturated polyester resin and other ...

Embodiment 3

[0043] Refer to attached figure 1 and figure 2 , the present invention is a reinforced composite material sleeper for rail transit, the sleeper includes a sleeper body and high-density polyurethane foam filled in the sleeper body; the sleeper body is made of the following raw materials in parts by weight: unsaturated polystyrene 100 parts of ester resin, 2 parts of initiator, 2 parts of liquid release oil, 50 parts of filler, 2 parts of viscosity reducer, 3 parts of auxiliary agent, 200 parts of a mixture of glass fiber, glass fiber mat and glass fiber multiaxial cloth, The ratio of glass fiber, glass fiber mat and glass fiber multiaxial cloth in the mixture is 60:10:30. Its filler is calcium carbonate. Its auxiliary agent is a silane coupling agent.

[0044]A production process for reinforced composite material sleepers for rail transit, comprising the following steps:

[0045] (1) According to the proportion of the formula, the unsaturated polyester resin and other ingr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com