Oil bath type temperature control fidelity coring device experiment platform

A temperature control and experimental platform technology, applied in sampling devices and other directions, can solve the problems of inability to verify the pressure resistance performance of the pressure-holding chamber, inability to simulate high temperature environments, unreliable experimental results, etc., to achieve reliable data, improve reliability and accuracy. , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

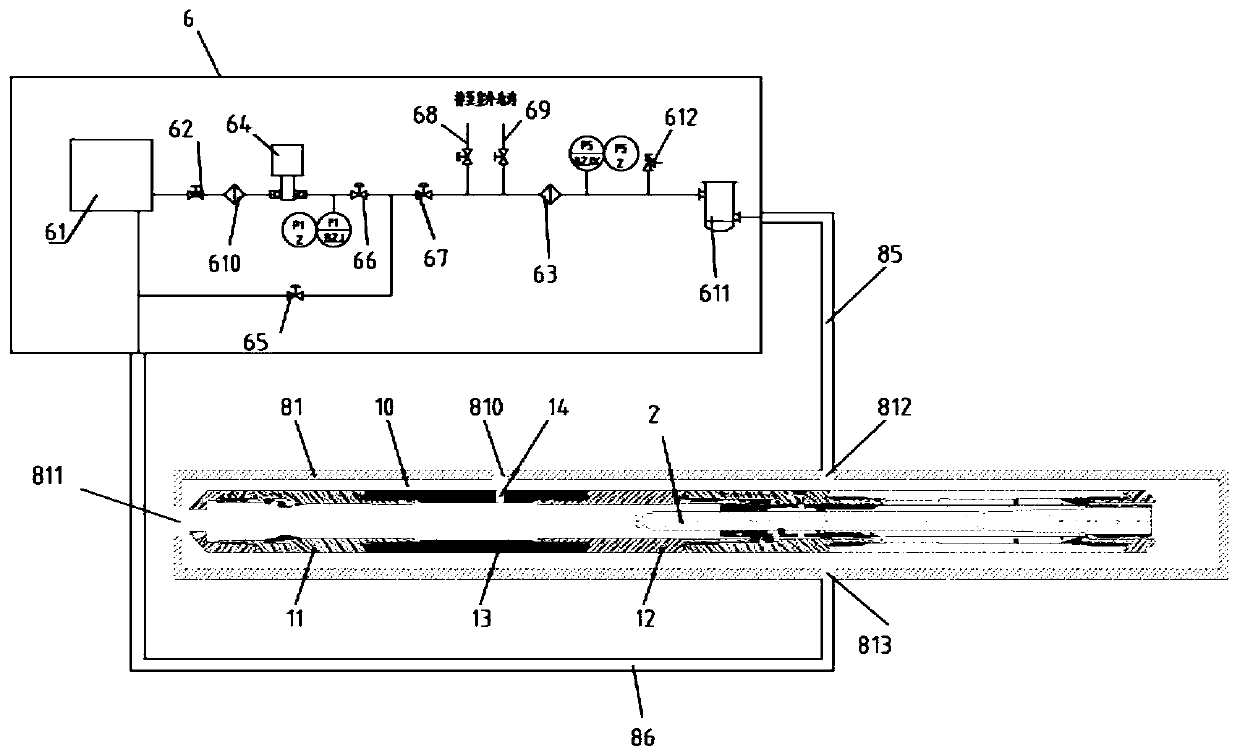

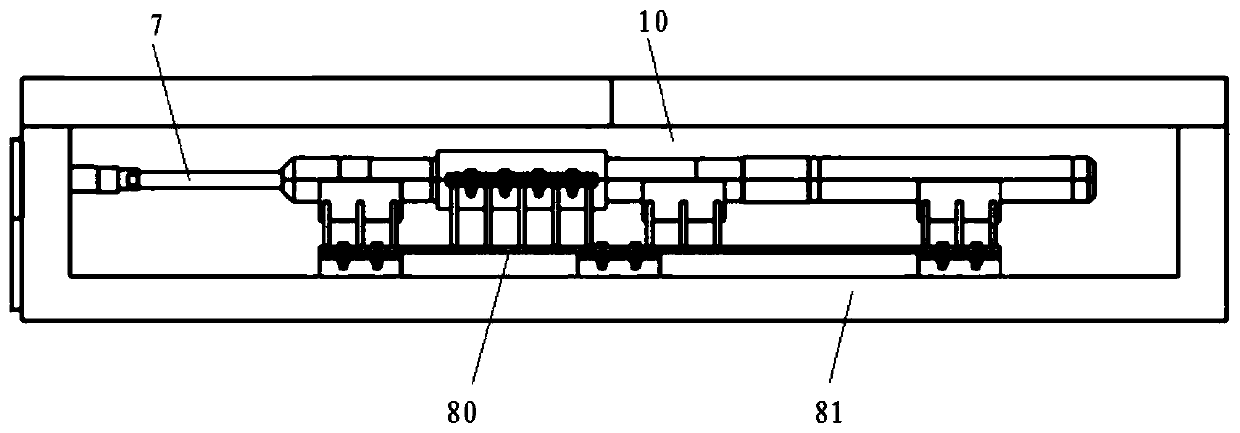

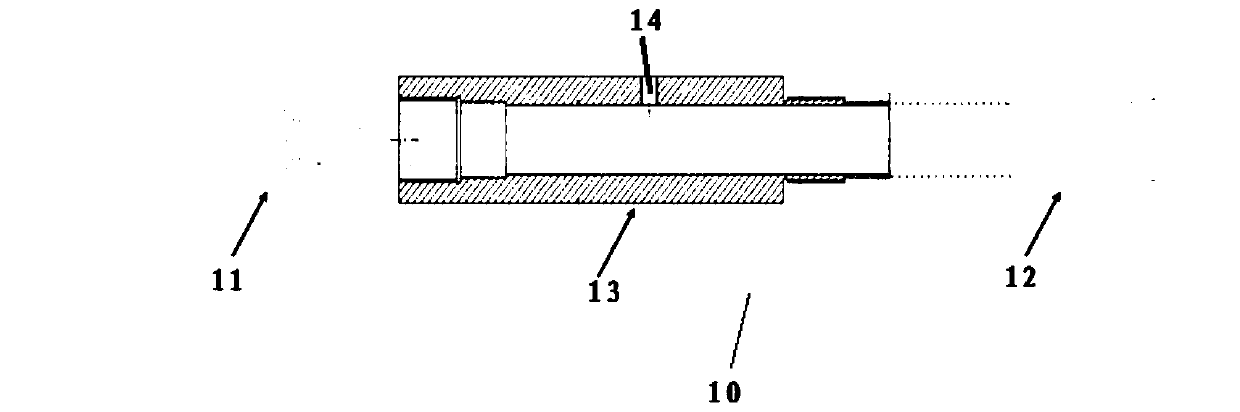

[0038] Such as figure 1 , 2 As shown, the oil bath temperature control fidelity corer experimental platform disclosed in the present invention includes a box body 81, a temperature control system 6 and a pressure test chamber 10 for simulating the fidelity corer fidelity chamber. The pressure test chamber 10 is placed in a box body 81 , and the box body 81 is provided with a mount 80 , and the pressure test chamber 10 is fixed on the mount 80 . Casing body 81 can select explosion-proof box.

[0039] The tank body 81 is provided with a liquid inlet 812 , a liquid outlet 813 and a first reserved hole 810 for the test pipeline to pass through. The liquid inlet 812 and the liquid outlet 813 are disposed on opposite sides of the box body 81 .

[0040] Temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com