Fidelity coring device experimental device and method based on multi-section temperature control feedback

A technology of experimental device and coring device, applied in sampling device, measuring device, temperature control and other directions, can solve the problems of inability to verify the pressure resistance performance of the pressure-holding chamber, inability to simulate high temperature environment, damage to the pressure-holding experimental chamber, etc. Reliable results, improved experimental efficiency, and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

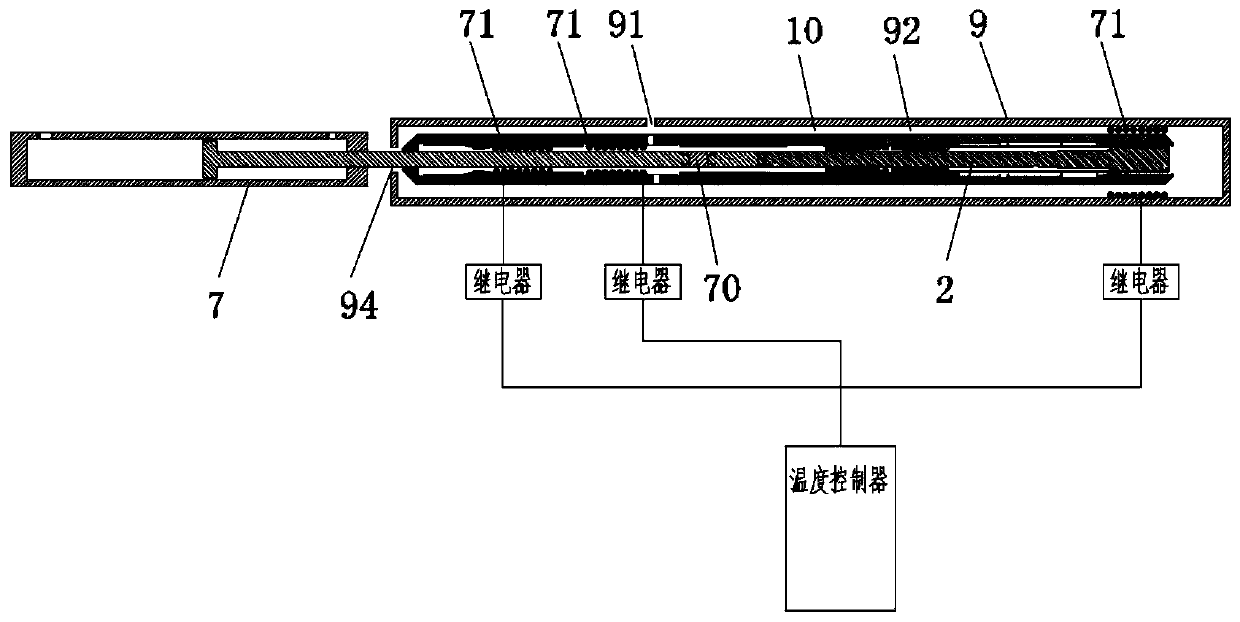

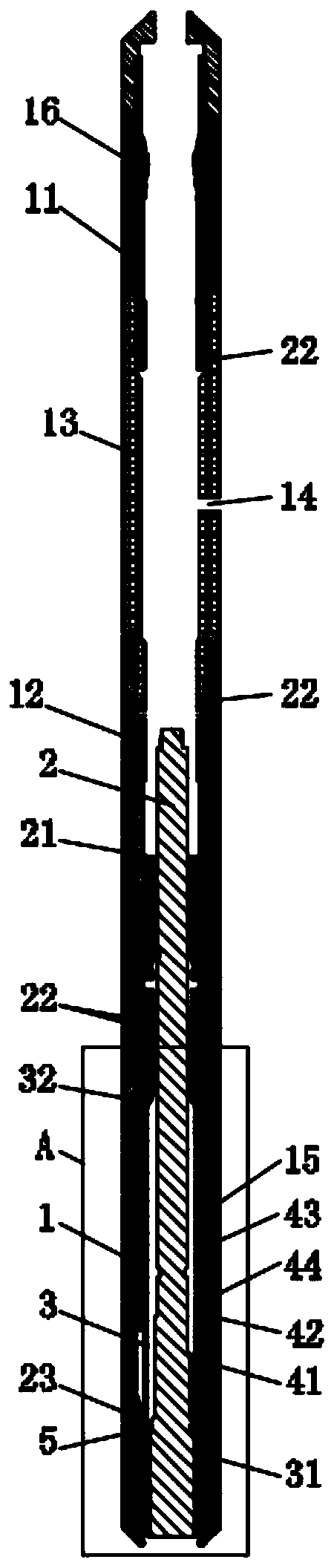

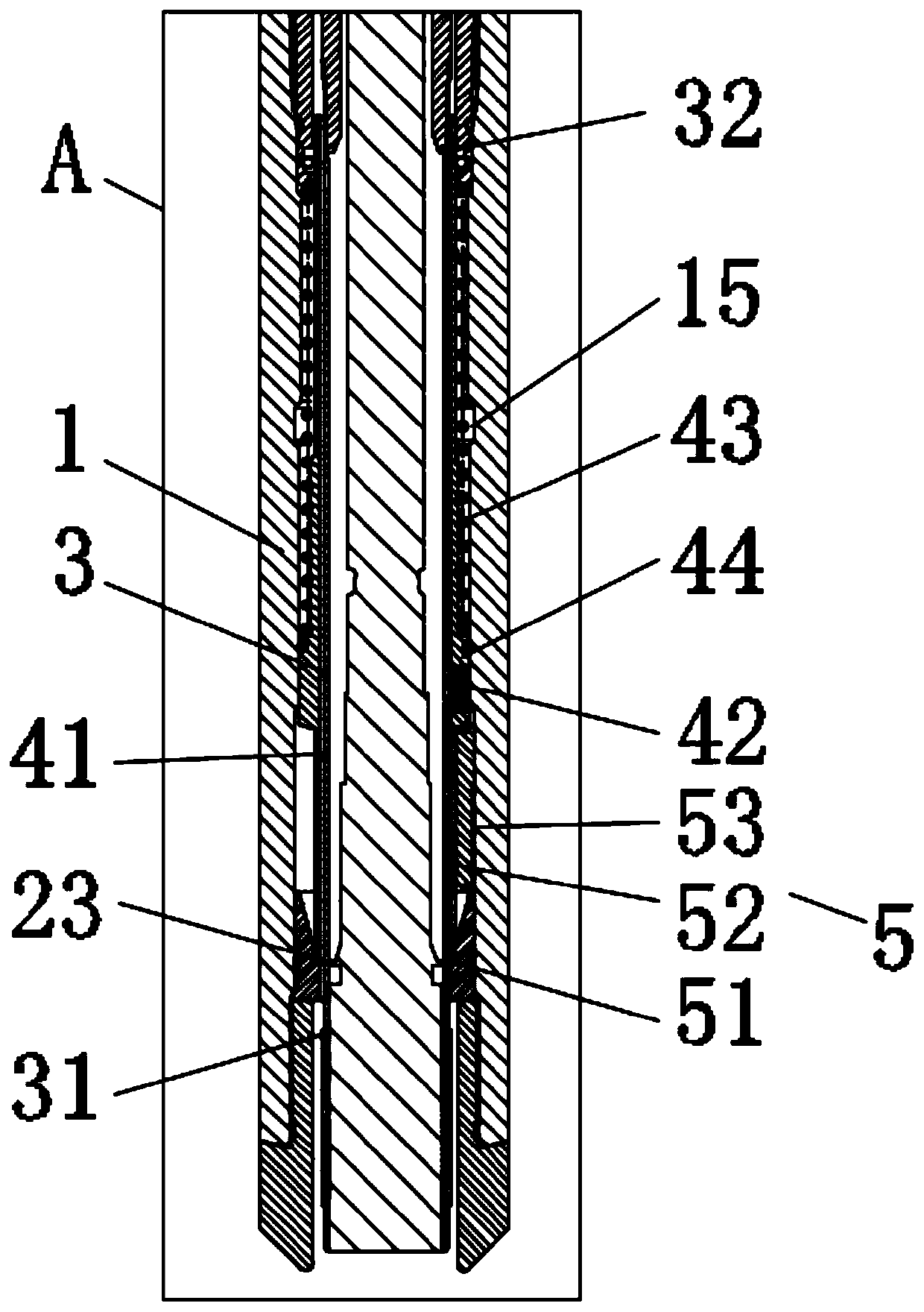

[0038] Such as figure 1 As shown, the fidelity corer experimental device based on multi-stage temperature control feedback disclosed by the present invention includes a pressure test chamber for simulating the fidelity corer fidelity chamber, and the pressure test chamber is arranged at intervals along the axial direction A plurality of electric heating devices 71 and a plurality of temperature measuring devices.

[0039] Each electric heating device 71 is connected with an automatic switch, and both the automatic switch and the temperature measuring device are electrically connected with the temperature controller. The automatic switch can choose a relay, and the temperature measuring device can choose a temperature sensor.

[0040] Wherein, the electric heating device 71 is arranged inside and / or outside the pressure test chamber. If the space is sufficient, all the electric heating devices 71 can be arranged inside the pressure test chamber; if the space is limited, a par...

specific Embodiment approach 2

[0072] In this embodiment, the electric heating device includes a graphene film. In order to facilitate the installation of the graphene film, the electric heating structure is fabricated by electroplating the graphene film on the aluminum cylinder. Specific as Figure 8 As shown, the graphene film 21 is plated on the inner cylinder wall of the aluminum cylinder 20, and the inner wall of the intermediate connector 13 is provided with an annular groove 19 for installing the aluminum cylinder 20, and the aluminum cylinder 20 electroplated with the graphene film 21 is embedded In the annular groove 19 of the inner wall of the intermediate connecting piece 13 . The depth of the annular groove 19 is set according to the thickness of the aluminum cylinder 20, for example, the depth of the annular groove 19 and the wall thickness of the aluminum cylinder 20 are both set to 3 mm.

[0073] The electric heating device on the test piece can be installed in the same way.

[0074] It sh...

specific Embodiment approach 3

[0076] The difference between this embodiment and Embodiments 1 and 2 is that: Figure 9 As shown, this embodiment also includes an external temperature control system 8 , a medium inlet 93 and a medium outlet 92 are provided on the box, and the medium inlet 93 and medium outlet 92 are connected to the external temperature control system 8 through pipelines.

[0077] The external temperature control system 8 includes two liquid tanks 81 and a pump 82, wherein the liquid in one liquid tank 81 is pumped to the medium inlet 93 of the tank by the pump 82, and the liquid in the tank is pumped from the medium outlet 92 by the other pump 82 To another liquid tank 81. The medium in the liquid tank 81 can be oil or water.

[0078] The external temperature control system 8 can be used as a heating system, and the medium in the liquid tank 81 is replaced with a heat medium, so that the pressure test chamber 10 can be heated externally, and the internal and external heating can be perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com