Tube-plate double-process supercritical water cooled reactor

A dual-process, supercritical technology, applied in the field of reactor structure, can solve the problems of a large number of parts, difficult manufacturing, installation, maintenance, and no access, etc., to achieve the effect of clear process channels, reduced complexity, and reasonable flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

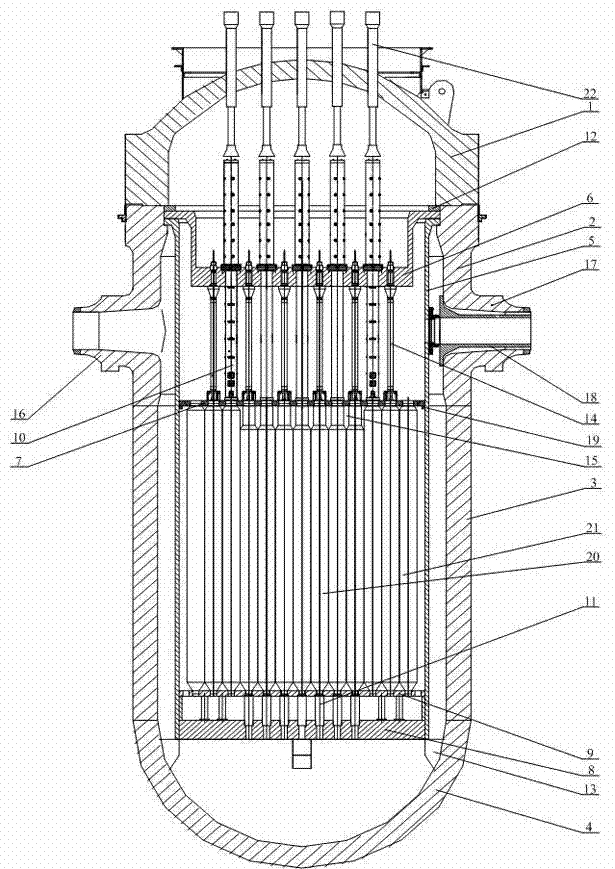

[0021] Such as figure 1 As shown, the tube-sheet type double-flow supercritical water-cooled reactor of the present invention is composed of a top cover 1, an upper cylinder body 2, a core section cylinder body 3, and a lower head 4 connected sequentially from top to bottom to form a reactor pressure vessel. 4. A radial support block 13 is provided on the inner side, and a plurality of holes are arranged on the radial support block 13. The hanging basket cylinder 5 is installed on the radial support block 13, and the upper support assembly 6 is installed on the top of the hanging basket cylinder 5. , the top of the upper support assembly 6 is a connecting flange, the upper support assembly 6 divides the inside of the reactor pressure vessel into upper and lower cavities, a spring 12 is installed between the flange and the top cover 1, and the spring is pressed The spring is used to fix the position of the basket cylinder, and a through hole is arranged in the axial direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com