Microporous-fiber composite sound absorbing board

A fiber composite, sound-absorbing board technology, applied in the direction of sound-generating equipment, instruments, etc., can solve the problem of not satisfying low-frequency sound absorption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

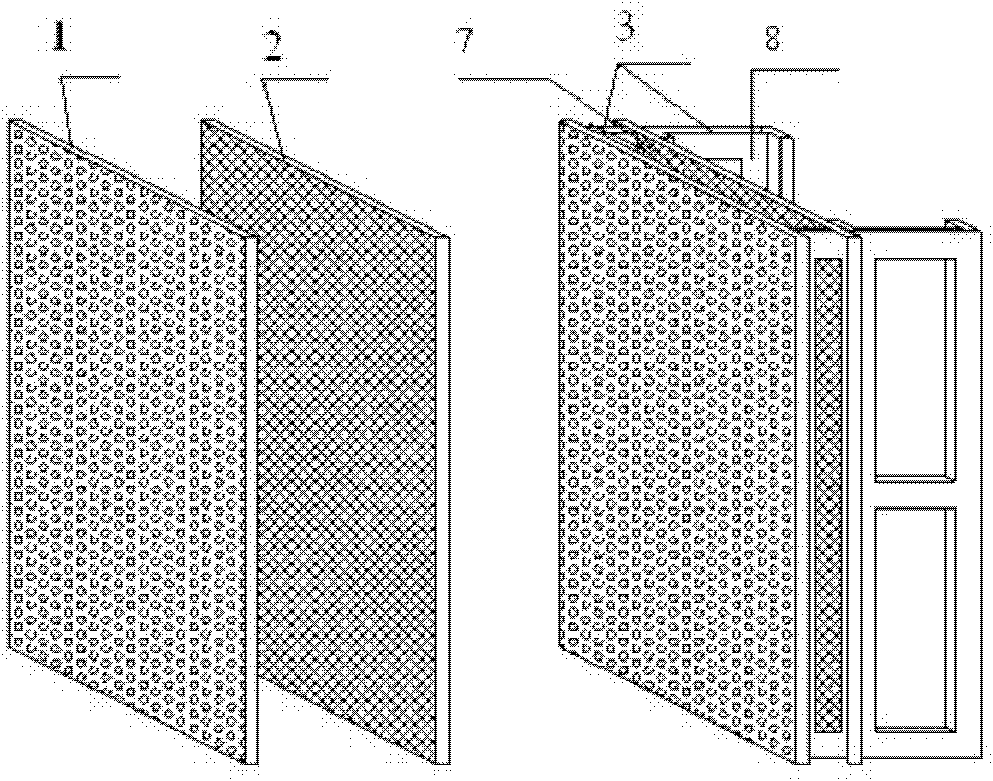

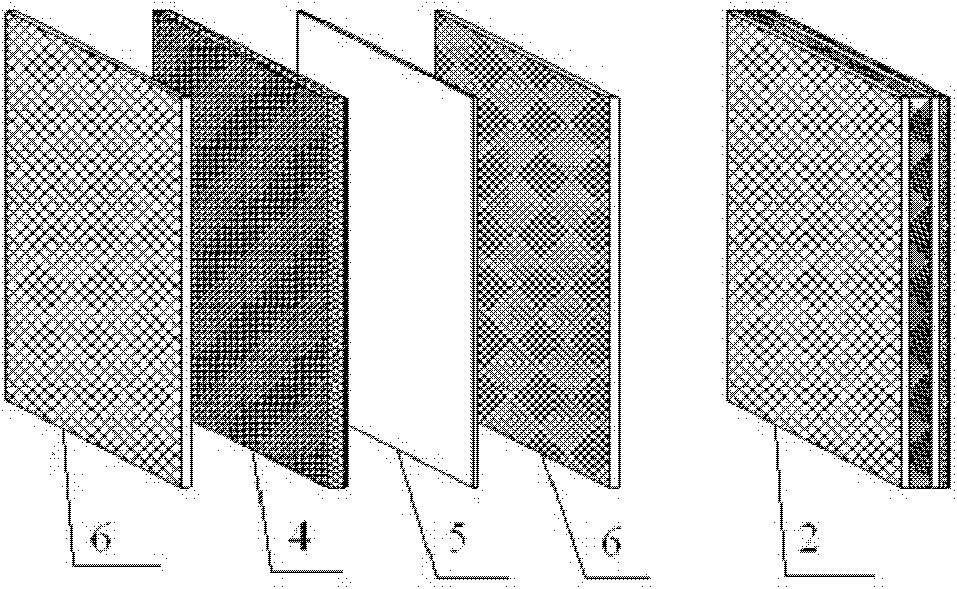

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Acoustic board 1#

[0065] Micro-perforated plate 1: Use commercially available 0.5mm aluminum plate to prepare micro-perforated plate 1, in which the hole spacing is 2mm and the aperture is 1.5mm;

[0066] Manufacturer Name: Zhongzhou Aluminum Co., Ltd.

[0067] Manufacturer Address: Kotou Industrial Zone, Xiaoguan Town, Gongyi City, Henan Province

[0068] Aluminum plate model: 1050 series aluminum plate

Embodiment 2

[0069] The aluminum plates in Example 2, Example 3 and Example 4 were all purchased from the aforementioned manufacturers.

[0070] Aluminum fiberboard 2: customized areal density is 300g / m 2 Aluminum fiber board 2, in which the aluminum fiber is prepared by melt extraction method, and the fiber diameter is 120 μm;

[0071] Combination: Combine the micro-perforated board 1 and the aluminum fiber board 2, and connect them through the keel 3. The distance between the micro-perforated board and the aluminum fiber board is 20mm, and the distance between the aluminum fiber board 2 and the wall is 180mm; the sound-absorbing board is made 1#;

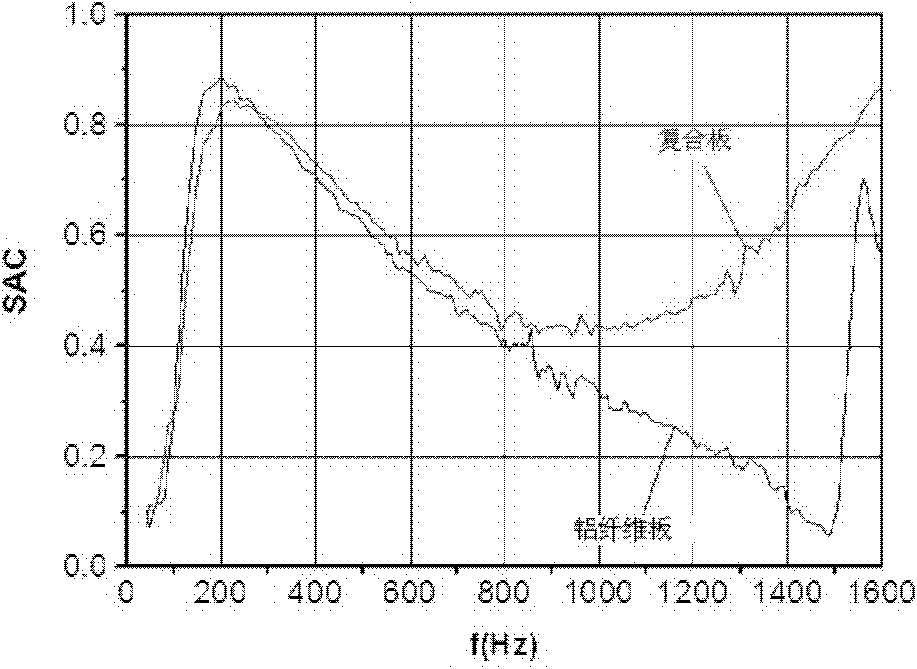

[0072] The sound absorption coefficient curve (red line) of sound absorption board 1# see image 3 , image 3 The sound absorption coefficient curve of the aluminum fiber sound-absorbing board (AL-fibre board) used as a comparative experiment in the test is represented by black lines. The distance between the aluminum fiber sound-absorbing board and...

Embodiment 3

[0078] Example 3: Acoustic board 3#

[0079] Micro-perforated plate 1: A commercially available 0.8mm aluminum plate is used to prepare the micro-perforated plate, the hole spacing is 15mm, and the aperture is 0.8mm;

[0080] Aluminum fiberboard 2: customized areal density is 500g / m 2 Aluminum fiber board, in which aluminum fiber is prepared by melt extraction method, and the fiber diameter is 90 μm;

[0081] Combination: Combine the micro-perforated board 1 and the aluminum fiber board 2, and connect them through the keel 3. The distance between the first resonance cavity 7 between the micro-perforated board 1 and the aluminum fiber board 2 is 60mm, and the second between the aluminum fiber board 2 and the wall The distance of the resonance cavity 8 is 120mm; it is made of sound-absorbing board 3#;

[0082] The sound absorption coefficient curve of sound-absorbing board 3# (red line) see Figure 5 , Figure 5 The sound absorption coefficient curve of the aluminum fiber sound-absorbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Face distance | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com