A tunable sub-wavelength low-frequency sound-absorbing structure

A sub-wavelength, sound-absorbing technology, used in sound-generating equipment, instruments, etc., can solve the problems of effective sound-absorbing frequency bandwidth, poor low-frequency sound-absorbing effect, limited porous materials, etc., achieve broadband high-efficiency sound absorption, and improve low-frequency sound absorption coefficient. , to achieve the effect of sound absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

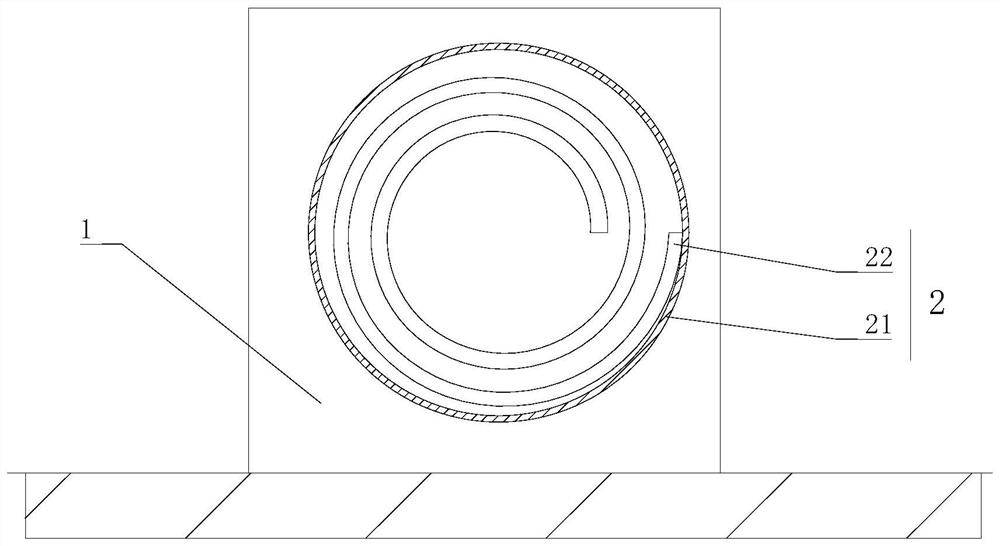

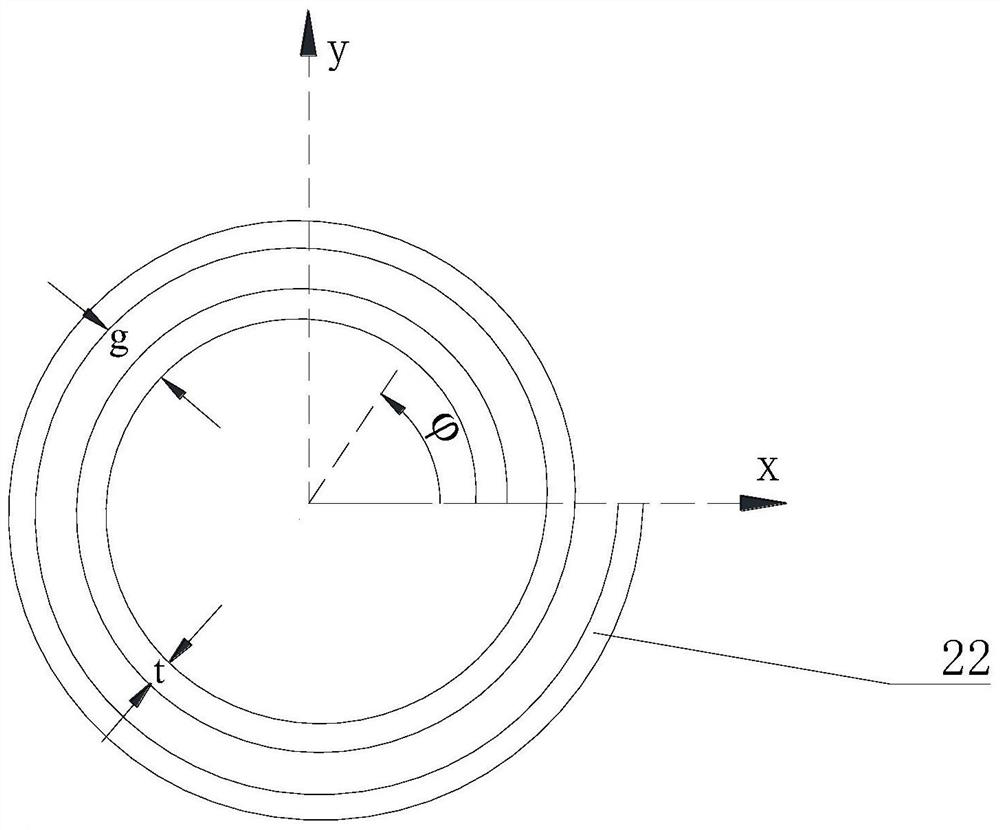

[0055] refer to figure 1 and figure 2 , the curled structure 2 includes a sound-absorbing unit 21 and a partition 22, the partition 22 is a spiral partition, and is in the shape of an Archimedes spiral, and the spiral partition is a rigid partition. Take the spiral center of the spiral partition as the coordinate system circle point, take the straight line from the origin to the starting point of the spiral partition as the x-axis, and take the horizontal straight line perpendicular to the x-axis as the y-axis to establish a plane Cartesian coordinate system, such as figure 2 shown. Among them, the inner edge of the spiral partition satisfies the following equation:

[0056]

[0057] Among them, m is the ordinal number of the Archimedes spiral coil,

[0058] is the space azimuth,

[0059] g is the interval between adjacent spirals of the Archimedes spiral, which is a constant,

[0060] r 0 for when polar diameter at time.

[0061] further,

[0062] Wherein, ...

Embodiment 2

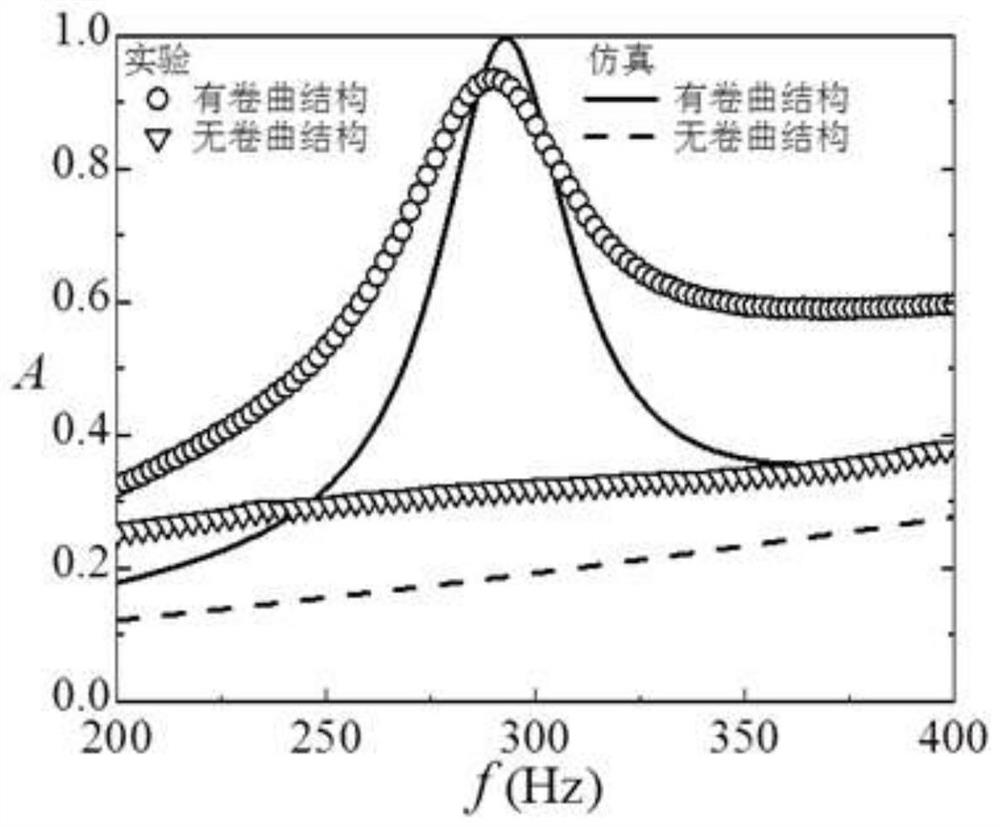

[0067] We adjust the parameters of the spiral partition in Example 1 to r 0 =16mm, The spatial azimuth angle in the range of -π-3π / 2, m=2, g=5mm, the thickness of the spiral partition t=1mm, and the opening angle θ=0°. The length, width and thickness of the porous material remain unchanged, and the parameters of the Johnson-Champoux-Allard model of the porous material remain unchanged. The sound absorption coefficient simulation result of embodiment 2 of the present invention sees Figure 4 .

[0068] from Figure 4 It can be seen in f 1 = 310Hz, f 2 =1130Hz, there are two perfect sound absorption coefficients respectively, and the single structure realizes the perfect sound absorption of double belts. f 1 corresponds to the fundamental resonance mode of the coiled structure, f 2 Corresponds to the higher-order resonance modes of the coiled structure. The frequency equal to 1379Hz corresponds to the bound mode of the structure. Due to the joint action of the bound mo...

Embodiment 3

[0070] An air cavity with a thickness of 30 mm is left between the composite sound-absorbing structure and the installation surface in Example 1 to simulate the situation where there is an air cavity between the composite sound-absorbing structure and the installation surface. The sound absorption coefficient of embodiment 3 of the present invention sees Figure 5 .

[0071] from Figure 5 It can be seen that the sound absorption coefficient of the composite sound-absorbing structure can reach more than 80% at 300Hz-1000Hz, and the sound absorption coefficient measurement results show that the existence of the air cavity greatly improves the low-frequency sound absorption performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com