Soft polyurethane foam and resonant cavity structure formed by same

A technology of soft polyurethane and resonant cavity, which is applied in the direction of instruments, sound-generating devices, etc., can solve the problems of multi-process and complicated process, and achieve simple preparation process, increase internal friction and viscous resistance, and excellent sound absorption and noise reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

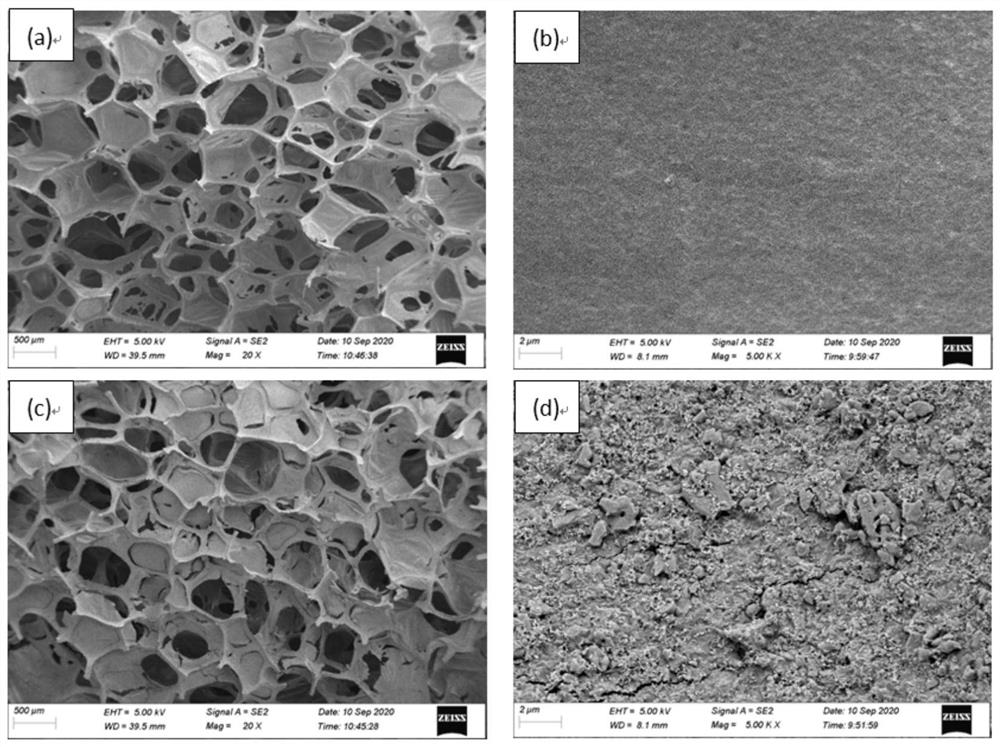

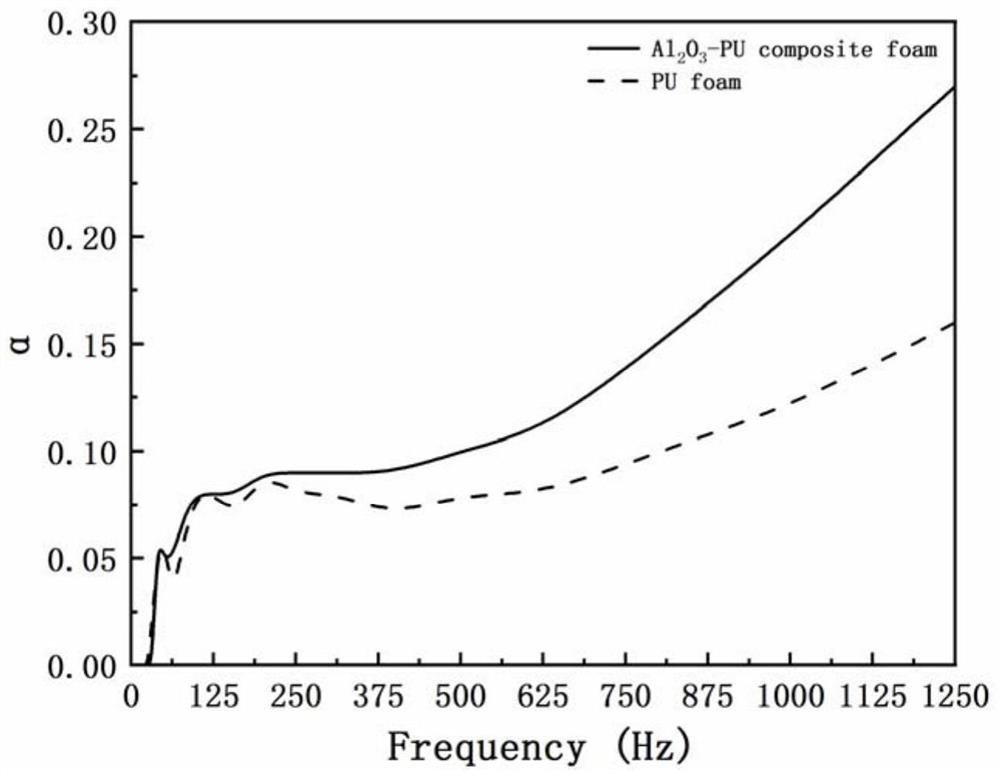

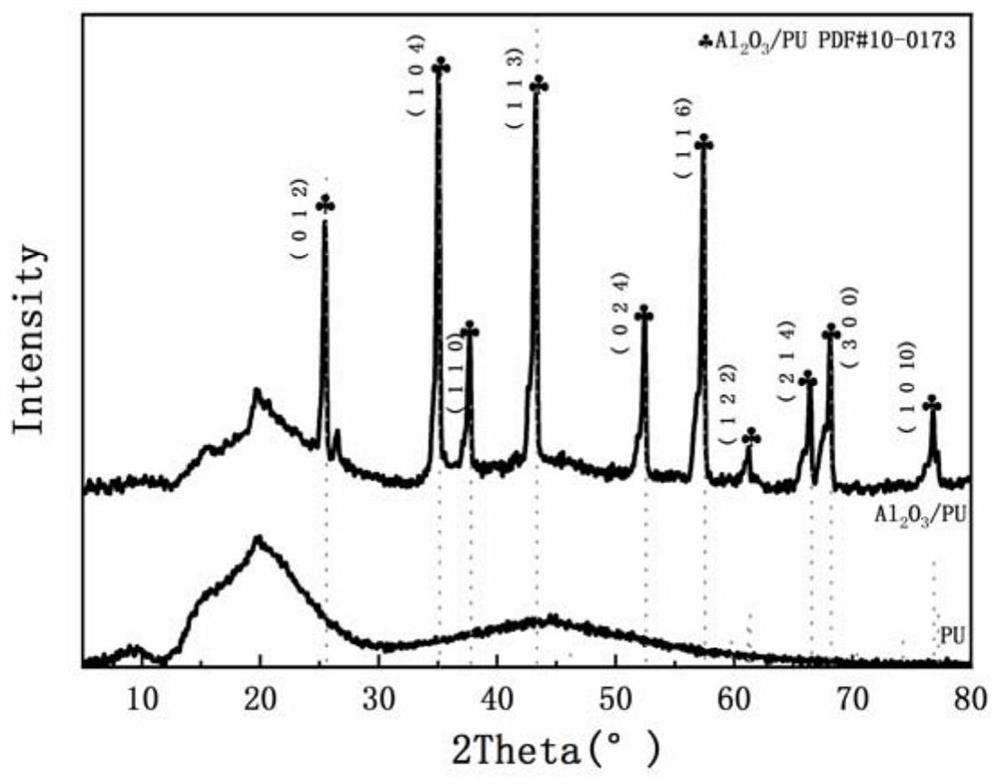

[0037] Put the treated PU foam into the petri dish, use 300nm particle size Al 2 o 3 The suspension is soaked and cultivated, so that the suspension is not over the surface of the foam, soaked for about 1 hour, the foam is clipped out with tweezers, put into another petri dish, and dried at 80°C until it is completely dry, and then placed at room temperature for a period of time For cooling, get Al 2 o 3 -PU foam. The 4206 type impedance tube is used, and the principle of the impedance tube to measure the sound absorption performance of the material is based on the transfer function method. Its principle is to decompose the broadband steady-state random signal into incident waves p i and the reflected wave p r ,p i and p r The size is determined by the sound pressure measured by two microphones installed on the pipe, and the sound absorption coefficient of the foam material (normal incidence sound absorption coefficient) is calculated.

[0038] figure 1 PU foam and Al...

Embodiment 2

[0041] The preparation method of Example 2 is carried out on the basis of Example 1, and the test method is as described in Example 1. Al will be prepared 2 o 3 -PU foam is bonded with plexiglass to form a resonant cavity structure, and air cavities of different heights are selected. The Al 2 o 3 - PU foam and plexiglass adhesive are epoxy resin and curing agent, and the configuration volume ratio is epoxy resin: curing agent = 5:1. The plexiglass structure is a circular bottom plate with a thickness of 5mm and a diameter of 100mm and a glass wall with a thickness of 5mm and an outer diameter of 100mm. 2 o 3 - PU foam cut to a diameter of 90mm and placed in this structure. The selected air cavity heights are 0mm and 10mm, Al 2 o 3 - The thickness of the PU foam is 20mm, and the height of the glass wall is 20mm and 30mm respectively.

[0042] Figure 4 It is the physical picture of the resonant cavity structure prepared in Example 2 of the present invention. The air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com