High-temperature-resistant sound insulation board

A sound insulation board and high temperature resistant technology, applied in the direction of sound insulation, heat preservation, building components, etc., can solve the problems of sound insulation and high temperature resistance, expand the frequency band of sound absorption and sound insulation, improve high temperature resistance and sound insulation performance, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

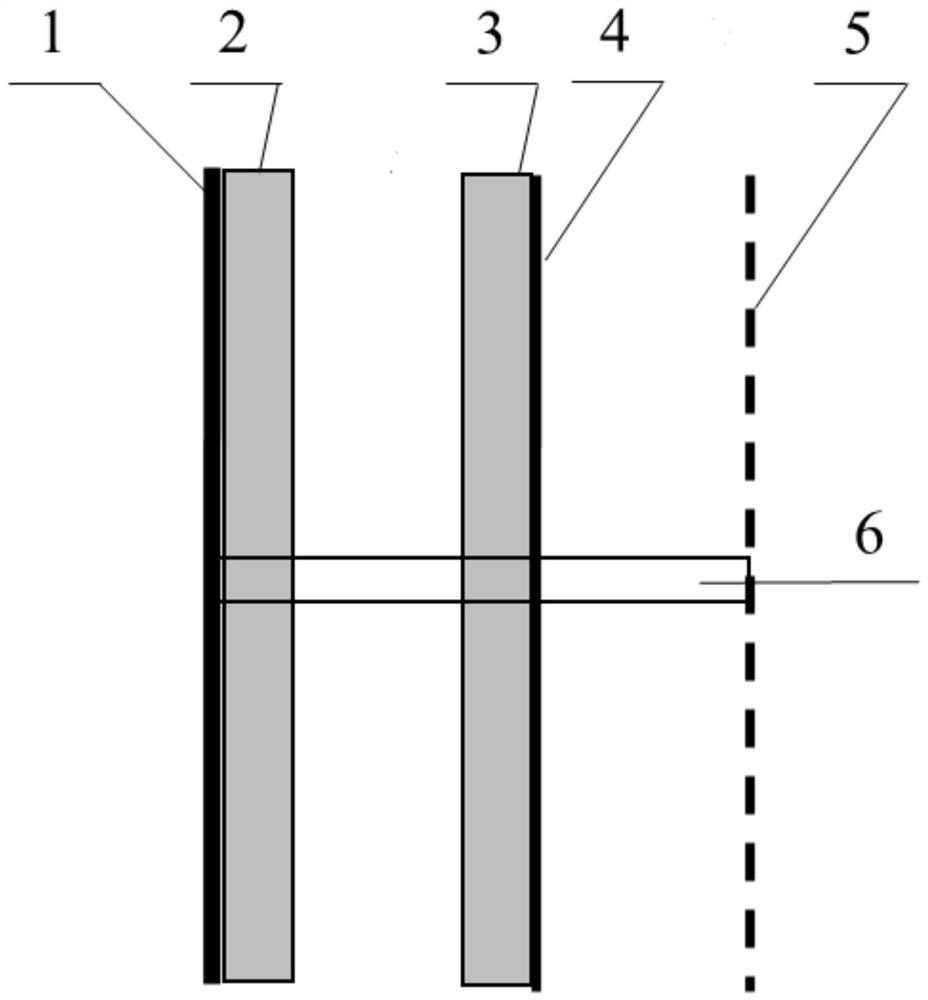

[0029] This embodiment provides a high temperature resistant sound insulation board, the structure of which is as follows figure 1 As shown, it includes a keel frame 6 and a carbon steel plate 1 passing through the keel frame 6 in turn, a first aluminum silicate fiber board 2, a second aluminum silicate fiber board 3, an aluminum foil 4 and a micro-perforated plate 5. The first silicon A first cavity is formed between the alumina fiber board 2 and the second aluminum silicate fiber board 3 , and a second cavity is formed between the aluminum foil 4 and the micro-perforated plate 5 .

[0030] Wherein, the spacing between the first aluminum silicate fiber board 2 and the second aluminum silicate fiber board 3 is 180 mm; the spacing between the aluminum foil 4 and the micro-perforated plate 5 is 80 mm; the first aluminum silicate fiber board 2, the second silicic acid Aluminum fiber board 3 has a thickness of 100mm and an area density of 100g / m 2 , the fiber diameter is 70 μm; t...

Embodiment 2

[0032] This embodiment provides a high-temperature-resistant sound insulation board, which includes a keel frame and carbon steel plates passing through the keel frame 6 in sequence, a first aluminum silicate fiber board, a second aluminum silicate fiber board, aluminum foil and a micro-perforated board. A first cavity is formed between an aluminum silicate fiber board and a second aluminum silicate fiber board, and a second cavity is formed between the aluminum foil and the micro-perforated plate.

[0033] Among them, the distance between the first aluminum silicate fiberboard and the second aluminum silicate fiberboard is 20mm; the distance between the aluminum foil and the micro-perforated plate is 80mm; the thickness of the first aluminum silicate fiberboard and the second aluminum silicate fiberboard is 50mm , surface density is 100g / m 2 , the fiber diameter is 70 μm; the micro-perforated plate is an aluminum plate with a thickness of 0.8 mm, a hole diameter of 0.8 mm, a ...

Embodiment 3

[0035] This embodiment provides a high-temperature-resistant sound insulation board, which includes a keel frame, carbon steel plates passing through the keel frame, a first aluminum silicate fiber board, a second aluminum silicate fiber board, aluminum foil, and a micro-perforated board. A first cavity is formed between the aluminum silicate fiber board and the second aluminum silicate fiber board, and a second cavity is formed between the aluminum foil and the micro-perforated plate.

[0036] Among them, the distance between the first aluminum silicate fiberboard and the second aluminum silicate fiberboard is 180mm; the distance between the aluminum foil and the micro-perforated plate is 20mm; the thickness of the first aluminum silicate fiberboard and the second aluminum silicate fiber is 150mm , surface density is 100g / m 2 , the fiber diameter is 70 μm; the micro-perforated plate is an aluminum plate with a thickness of 0.8 mm, a hole diameter of 0.8 mm, a hole spacing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com