Carbon aerogel material, preparation method thereof, and application of carbon aerogel material as heavy metal contaminated soil remediation material

A carbon aerogel and metal technology, applied in the field of ecological environment management, can solve the problems of lack of high-performance environmental functional materials, heavy metal pollution, etc., and achieve the effect of low density, less addition, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

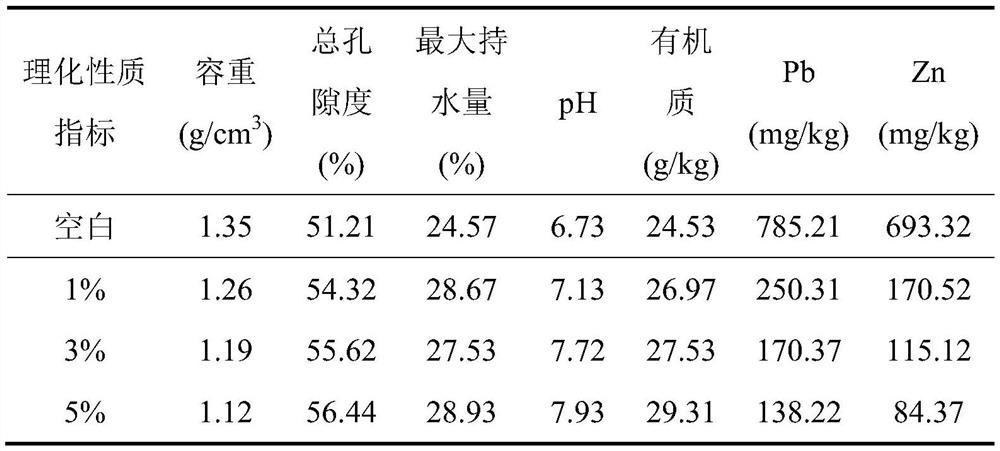

Examples

Embodiment 1

[0033] In a 250mL beaker, add 25g of novolac resin, 5g of diethylenetriamine, 0.6g of solid anhydrous aluminum trichloride and 100ml of ethanol, stir vigorously, pour into a hydrothermal reaction kettle, and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 4 days. After the reaction, a yellow solid appeared, and the yellow solid was taken out and dried in vacuum for 24 hours. Under a nitrogen atmosphere, heat in a tube furnace at 800°C for 4 hours, take out the black solid after cooling, grind it and pass it through a 60-mesh sieve, wash the finely sieved solid with dilute hydrochloric acid to remove metal salts, and then wash it with pure water to the washing liquid When the pH is constant, the carbon airgel material with aluminum trichloride imprint is obtained. The carbonization yield of the carbon airgel is: 53.5%, and the specific surface area is 660m 2 / g, average pore diam...

Embodiment 2

[0035] In a 250mL beaker, add 25g of novolac resin, 5g of hexamethylenetetramine, 0.61g of solid zinc chloride and 100ml of ethanol, stir vigorously, pour into the hydrothermal reaction kettle, and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 6 days. After the reaction, a yellow solid appeared, and the yellow solid was taken out and freeze-dried. Under nitrogen atmosphere, heat in a tube furnace at 600°C for 6 hours, take out the black solid after cooling, pass through a 60-mesh sieve after grinding, wash the sieved solid with dilute hydrochloric acid and dilute nitric acid to remove metal salts, and then wash with pure water Until the pH of the washing solution is constant, a carbon airgel material with zinc chloride imprints is obtained. The carbonization yield of the carbon airgel is: 55.24%, and the specific surface area is 968m 2 / g, average pore diameter: 786nm, pore vo...

Embodiment 3

[0036] Embodiment 3 (the comparative example that does not add metal chloride salt)

[0037] In a 250mL beaker, add 25g of novolac resin, 5g of hexamethylenetetramine and 100ml of ethanol, stir vigorously, pour into the hydrothermal reaction kettle, and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 6 days. After the reaction, a yellow solid appeared, and the yellow solid was taken out and freeze-dried. Under a nitrogen atmosphere, heat in a tube furnace at 600°C for 6 hours, and take out the black solid after cooling to obtain the carbon airgel material. The carbonization yield of the carbon airgel is: 51.57%, and the specific surface area is 413m 2 / g, average pore diameter: 452nm, pore volume: 2.11cm 3 / g. This example shows that when no metal chloride salt is used as a template, the obtained carbon aerogel has a low specific surface area and an undeveloped pore structure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com