Manufacturing method for forming recycled fabric into plastic-containing pellets, and plastic-containing pellet

A manufacturing method and technology of plastic granules, applied in the field of plastic granules, can solve problems such as waste and harm to the earth's ecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

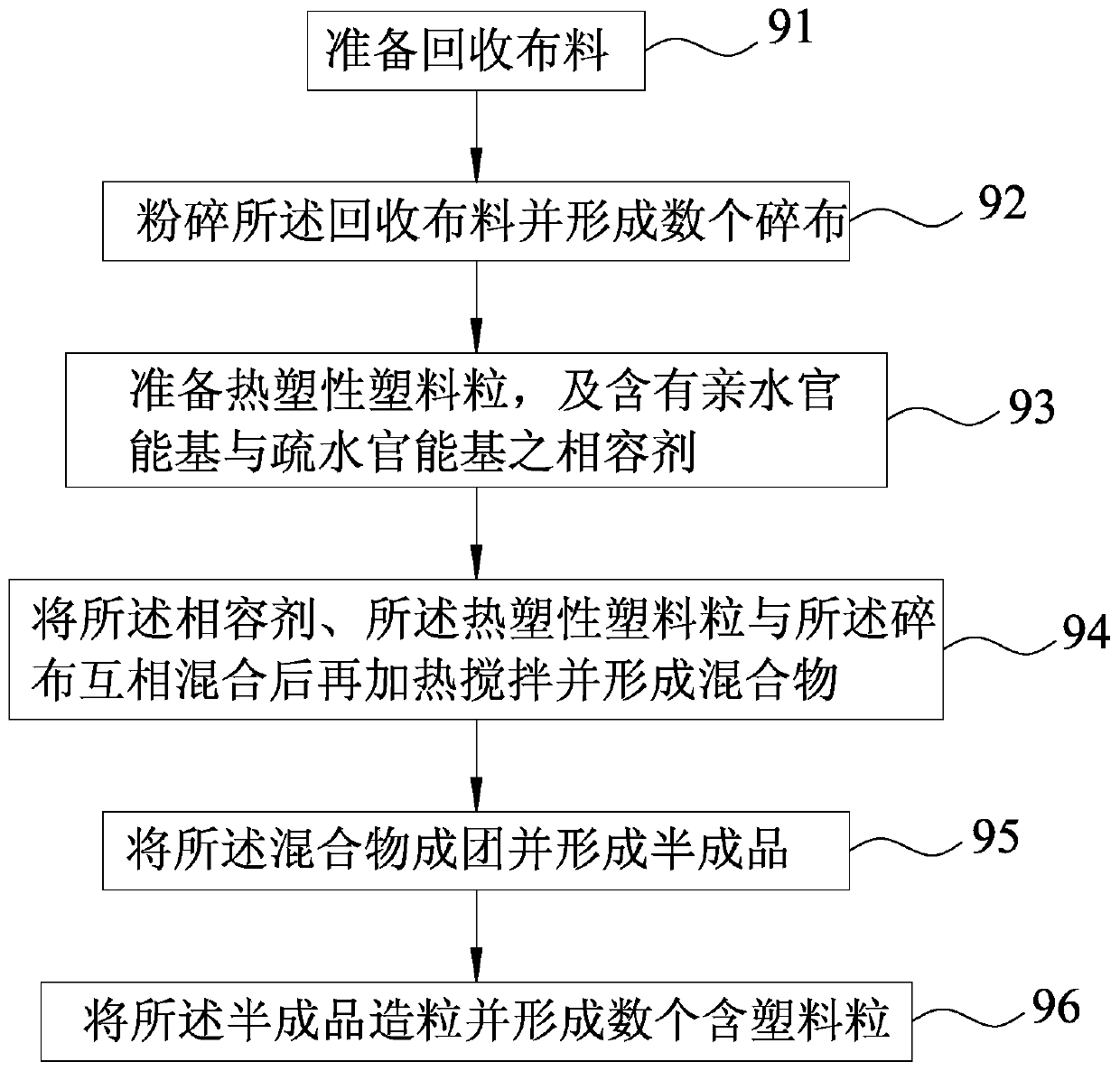

[0030] refer to figure 1 , the present invention makes recycled cloth into a first embodiment of the manufacturing method containing plastic granules, comprising the following steps:

[0031] Step 91: Prepare recycled fabrics, the recycled fabrics come from textile waste made of fabrics such as clothes, towels, bedding, bed sheets, hats, and bags. In the first embodiment, the recycled fabric contains pure cotton. It can be understood that, in other variations, the recycled fabric can also contain both pure cotton and artificial fibers.

[0032] Step 92: Putting the recycled cloth into a cloth shredder to crush the recycled cloth and form several 10 cm 2 The following rags. Preferably, the area of each rag is 2cm 2 to 4cm 2 .

[0033] Step 93: Prepare thermoplastic pellets and a compatibilizer containing hydrophilic functional groups and hydrophobic functional groups. The material of the thermoplastic pellets is selected from the following group: polyethylene (polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com