Method for regenerating waste lubricating oil by combining solvent extraction with composite metal oxide adsorbent

A technology of adsorbent regeneration and composite metal, which is applied in the direction of lubricating compositions, etc., to achieve the effects of high yield, high oil yield and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

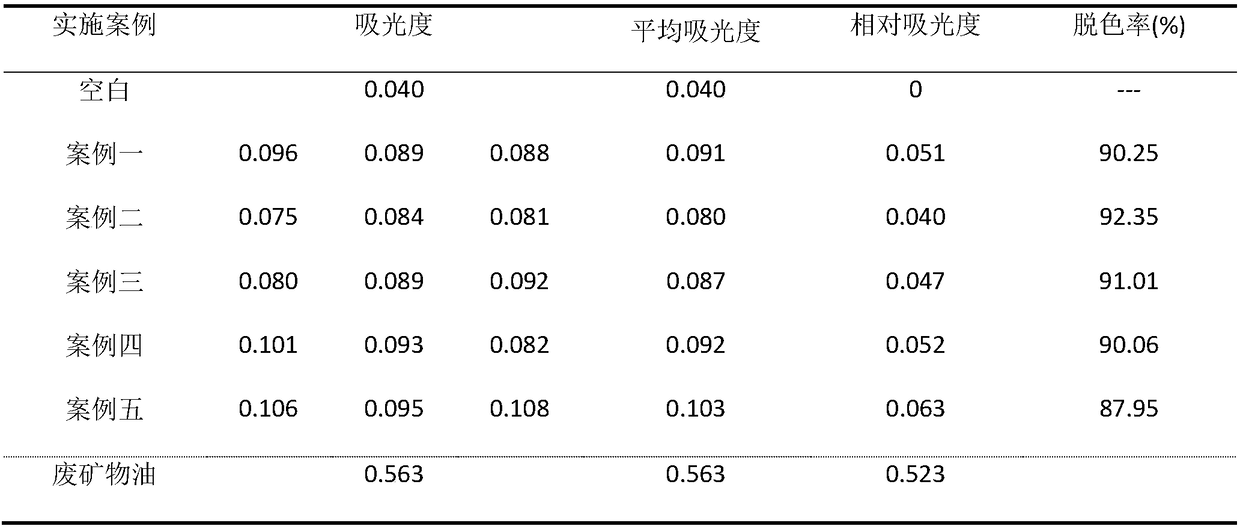

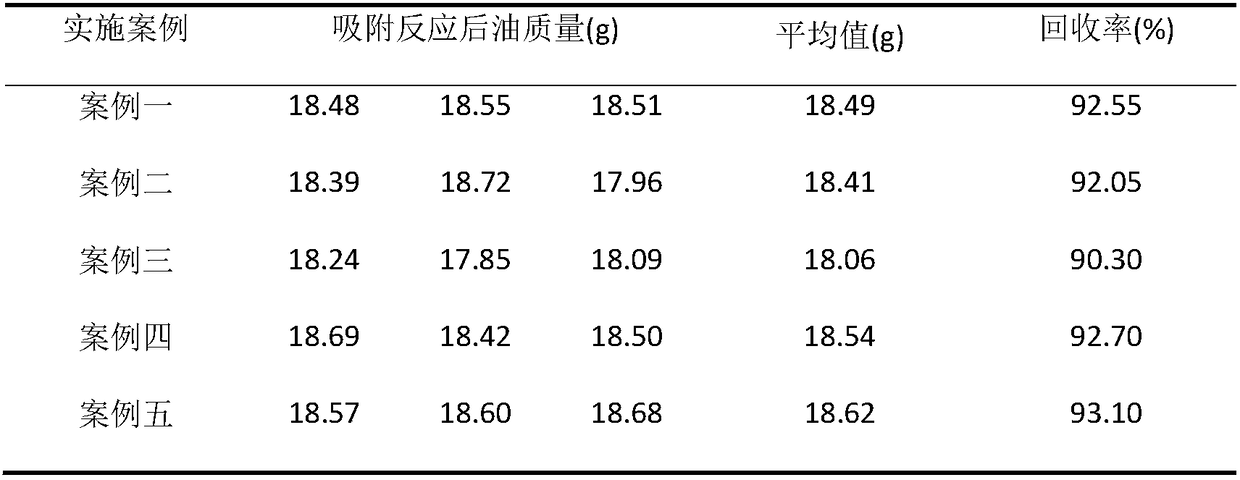

Examples

Embodiment 1

[0025] In this embodiment, a method for regenerating waste lubricating oil by solvent extraction combined with a composite metal oxide adsorbent comprises the following steps:

[0026] a. Weigh 60mmol of anhydrous CaCl respectively 2 , 5mmol of FeCl 3 ·6H 2 O and 25mmol of AlCl 3 ·6H 2 O, dissolved in 50 mL without CO 2 Prepare a mixed salt solution in water, and at the same time weigh 160mmol of NaOH and dissolve it in 100mL deionized water to prepare a mixed alkali solution. Under normal temperature conditions, under the action of magnetic stirring, slowly add the mixed salt solution to the NaOH solution. After stirring for 2 hours, Carry out static aging, after aging for 4 hours, take out suction filtration, wash with water 2 to 3 times, dry at 105°C to obtain ternary metal hydroxide, and then calcinate the ternary metal hydroxide at 750°C for 3 hours , and then grind and crush the calcined product to obtain a composite metal oxide decolorizer, which is used as a compo...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

[0034] In this embodiment, a method for regenerating waste lubricating oil by solvent extraction combined with a composite metal oxide adsorbent comprises the following steps:

[0035] a. Weigh 60mmol of anhydrous CaCl respectively 2 , 5mmol of FeCl 3 ·6H 2 O and 25mmol of AlCl 3 ·6H 2 O, dissolved in 50 mL without CO 2 Mixed salt solution was prepared in water. At the same time, 160 mmol of NaOH was dissolved in 100 mL of deionized water to prepare a mixed alkali solution. Under normal temperature conditions, under the action of magnetic stirring, the mixed salt solution was slowly added to the NaOH solution. After stirring for 5 hours, Carry out static aging, after aging for 4 hours, take out suction filtration, wash with water 2 to 3 times, dry at 105°C to obtain ternary metal hydroxide, and then calcinate the ternary metal hydroxide at 750°C for 3 hours , and then grind and crush the ...

Embodiment 3

[0042] This embodiment is basically the same as the previous embodiment, and the special features are:

[0043] In this embodiment, a method for regenerating waste lubricating oil by solvent extraction combined with a composite metal oxide adsorbent comprises the following steps:

[0044] a. Weigh 60mmol of anhydrous CaCl respectively 2 , 5mmol of FeCl 3 ·6H 2 O and 25mmol of AlCl 3 ·6H 2 O, dissolved in 50 mL without CO 2 Mixed salt solution was prepared in water. At the same time, 160 mmol of NaOH was dissolved in 100 mL of deionized water to prepare a mixed alkali solution. Under normal temperature conditions, under the action of magnetic stirring, the mixed salt solution was slowly added to the NaOH solution. After stirring for 4 hours, Carry out static aging, after aging for 4 hours, take out suction filtration, wash with water 2 to 3 times, dry at 105°C to obtain ternary metal hydroxide, and then calcinate the ternary metal hydroxide at 750°C for 3 hours , and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com