Method for innocent treatment of secondary aluminum ash by weakly alkaline water washing

A harmless treatment and weakly alkaline water technology, applied in chemical instruments and methods, inorganic chemistry, sustainable waste treatment, etc., can solve problems such as complex cost, complex cost of equipment, difficult separation, etc., to achieve convenient and stable recycling, The effect of solving overcapacity and meeting usage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The secondary aluminum ash is selected from the aluminum ash of Henan Borun Casting Materials Co., Ltd., and the content of metal aluminum is 15%.

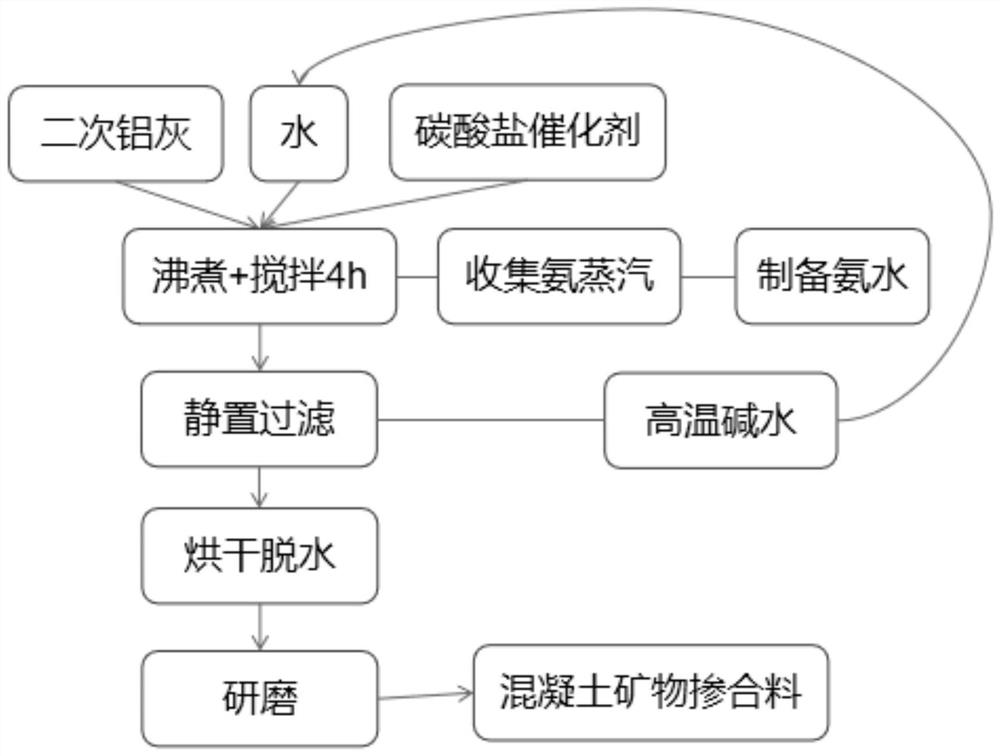

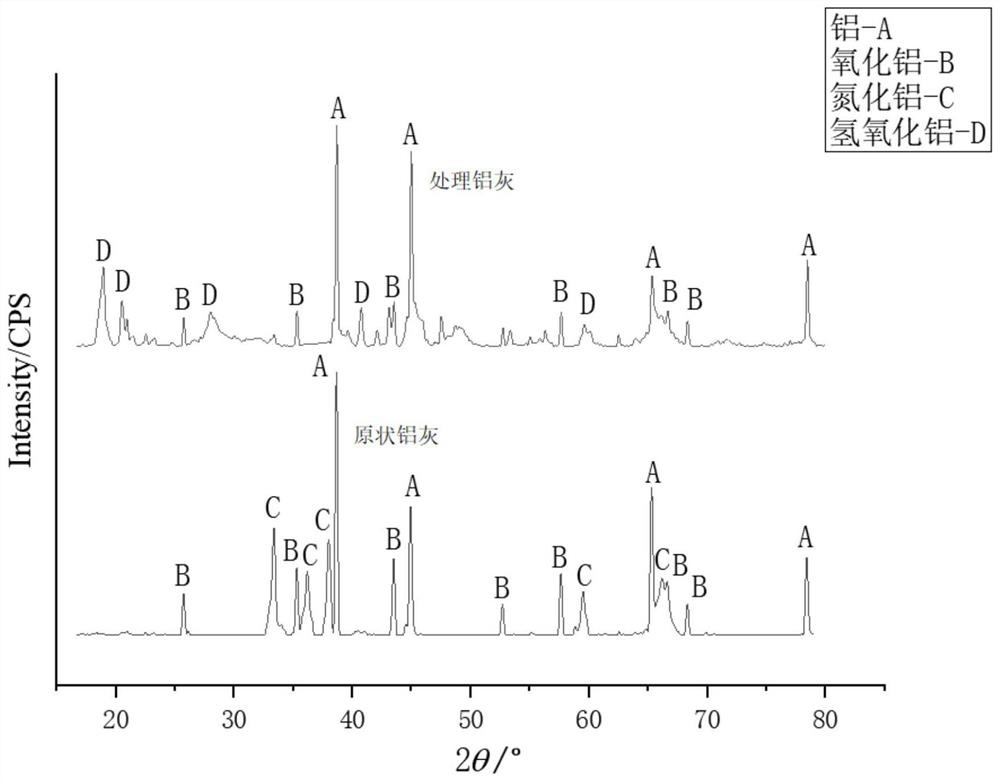

[0049] First heat 70kg of tap water to boiling and the temperature is 90°C, then add 25kg of secondary aluminum ash and 1kg of sodium carbonate into the water for stirring and mixing, the generated high-temperature ammonia vapor is collected through a condenser tube to collect the condensate, and the remaining gas is introduced into a water tank for filtration Then, the solution was kept stirring at a constant speed and kept at a constant temperature for 6 hours; the secondary aluminum ash was precipitated and filtered, and dried and ground. By XRF analysis, the nitrogen removal rate was 98.4%.

[0050] After the reaction, the recovery method of sodium carbonate is:

[0051] Evaporate and crystallize the recycled high-temperature alkaline water to obtain sodium carbonate powder with a small amount of impurities.

Embodiment 2

[0053] The secondary aluminum ash is selected from the aluminum ash of Henan Borun Casting Materials Co., Ltd., and the content of metal aluminum is 15%.

[0054] First, heat 80kg of tap water to boiling and the temperature is 85°C, then add 30kg of secondary aluminum ash and 1kg of sodium carbonate into the water for stirring and mixing, and the generated high-temperature ammonia vapor is collected through a condenser tube to collect the condensate, and the remaining gas is introduced into a water tank for filtration Then, the solution was kept stirring at a constant speed and kept at a constant temperature for 7 hours; the secondary aluminum ash was precipitated and filtered, and dried and ground. By XRF analysis, the nitrogen removal rate was 98%.

Embodiment 3

[0056] The secondary aluminum ash is selected from the aluminum ash of Henan Borun Casting Materials Co., Ltd., and the content of metal aluminum is 15%.

[0057] First heat 40kg of tap water to 80°C, then add 10kg of secondary aluminum ash and 0.5kg of potassium carbonate into the water for stirring and mixing, the generated high-temperature ammonia vapor is collected through the condenser tube to collect the condensate, and the remaining gas is introduced into the water tank for filtration and discharge; The solution was kept stirring at a constant speed and kept at a constant temperature for 8 hours; the secondary aluminum ash was precipitated and filtered, and dried and ground. By XRF analysis, the nitrogen removal rate was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com