Lignosulfonate-phenolic resin based carbon aerogel microsphere as well as preparation method and application thereof

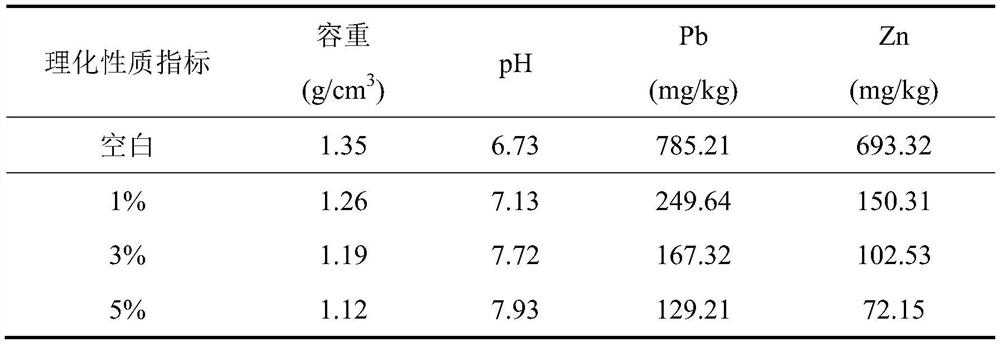

A technology of lignosulfonate and phenolic resin, applied in application, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of lack of high-performance environmental functional materials, soil heavy metal pollution, etc., achieve low density, use The method is simple and the effect of soil volume increase is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 (control experiment)

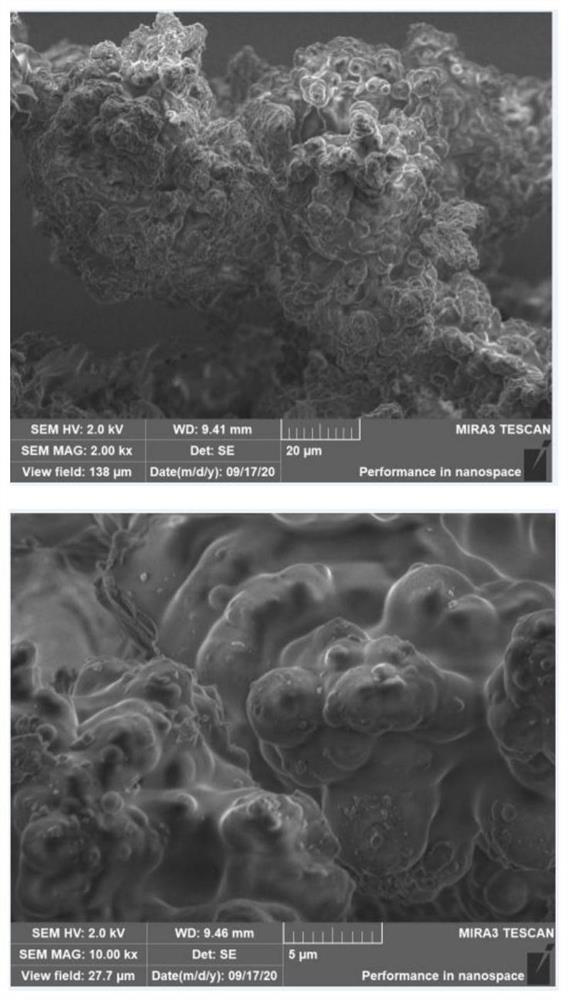

[0038] In a 250mL three-necked flask, add 12.98g of resorcinol, 4g of hexamethylenetetramine, 18.97ml of formaldehyde, add deionized water to make the volume to 40ml, stir evenly, pour 120ml of peanut oil, and use 300r / min continue to stir and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 100 minutes. After the reaction, brown solid particles appeared. After filtration, the yellow solid was taken out and aged at 80°C for 5 days. After aging, the residual peanut oil on the surface was washed away, and after vacuum drying, it was heated in a tube furnace at 800°C for 4 hours under a nitrogen atmosphere. After cooling, the black solid was taken out to obtain carbon airgel microspheres without imprinting. The carbonization yield of the carbon airgel is: 53.5%, the average particle size is 120μm, and the specific surface area is 470m 2 / ...

Embodiment 2

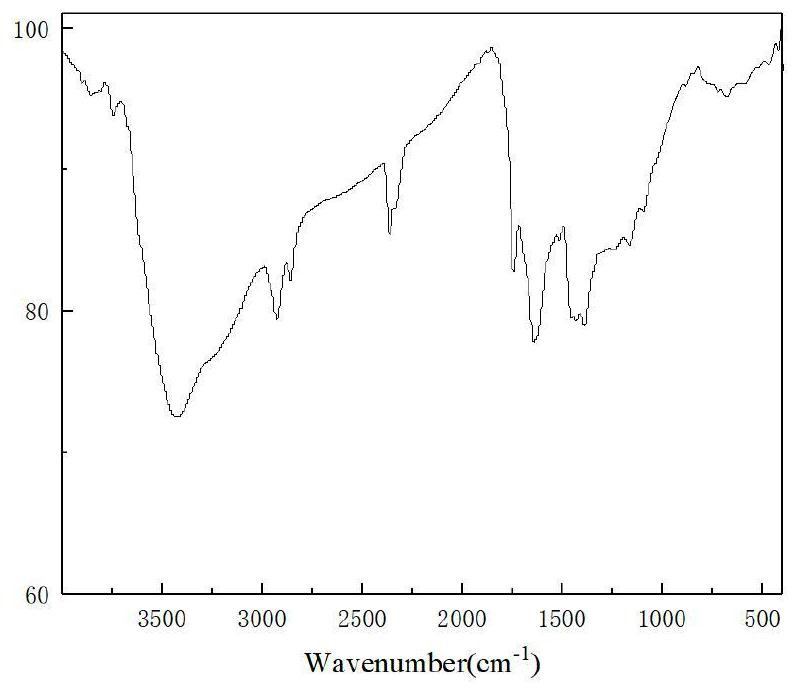

[0040] In a 250mL three-necked flask, add 8.98g of resorcinol, 4.02g of sodium lignosulfonate, 4g of hexamethylenetetramine, and 18.97ml of formaldehyde, add deionized water to make it 40ml, and stir evenly. Pour in 120ml of peanut oil, continue stirring at 450r / min, and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 100 minutes. After the reaction, brown solid particles appeared. After filtration, the yellow solid was taken out and aged at 80°C for 5 days. After aging, wash off the residual peanut oil on the surface. After vacuum drying, heat in a tube furnace at 300°C for 4 hours in a nitrogen atmosphere. After cooling, take out the black solid and wash it with pure water until the pH is constant. glue microspheres. The carbonization yield of the carbon airgel is: 51.3%, the average particle size is 78μm, and the specific surface area is 615m 2 / g, average pore diameter: 131...

Embodiment 3

[0043] In a 250mL three-necked flask, add 9.02g of resorcinol, 3.98g of zinc lignosulfonate, 2g of hexamethylenetetramine, 18.97ml of formaldehyde, add deionized water to make it 40ml, and stir evenly. Pour in 120ml peanut oil, continue stirring at 600r / min, and start heating. When the reaction reaches the set temperature, start timing. The reaction was carried out at a reaction temperature of 80° C. for 100 minutes. After the reaction, brown solid particles appeared. After filtration, the yellow solid was taken out and aged at 80°C for 5 days. After aging, wash off the residual peanut oil on the surface. After vacuum drying, heat in a tube furnace at 800°C for 4 hours under a nitrogen atmosphere. After cooling, take out the black solid, wash with 1mol / L hydrochloric acid three times to remove zinc ions, and then wash with pure water until the pH is constant. That is, carbon airgel microspheres with zinc ion imprinting are obtained. The carbonization yield of the carbon air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com