Method for denitrifying rare earth ore wastewater by using supported microalgae

A rare earth ore, load-type technology, applied in mining wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of no carbon source in wastewater, long process flow, waste of resources, etc., and achieve total nitrogen and ammonia nitrogen removal capacity. High, simple process operation equipment, the effect of improving the nitrogen removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Contrast experiment with or without corn cob carrier

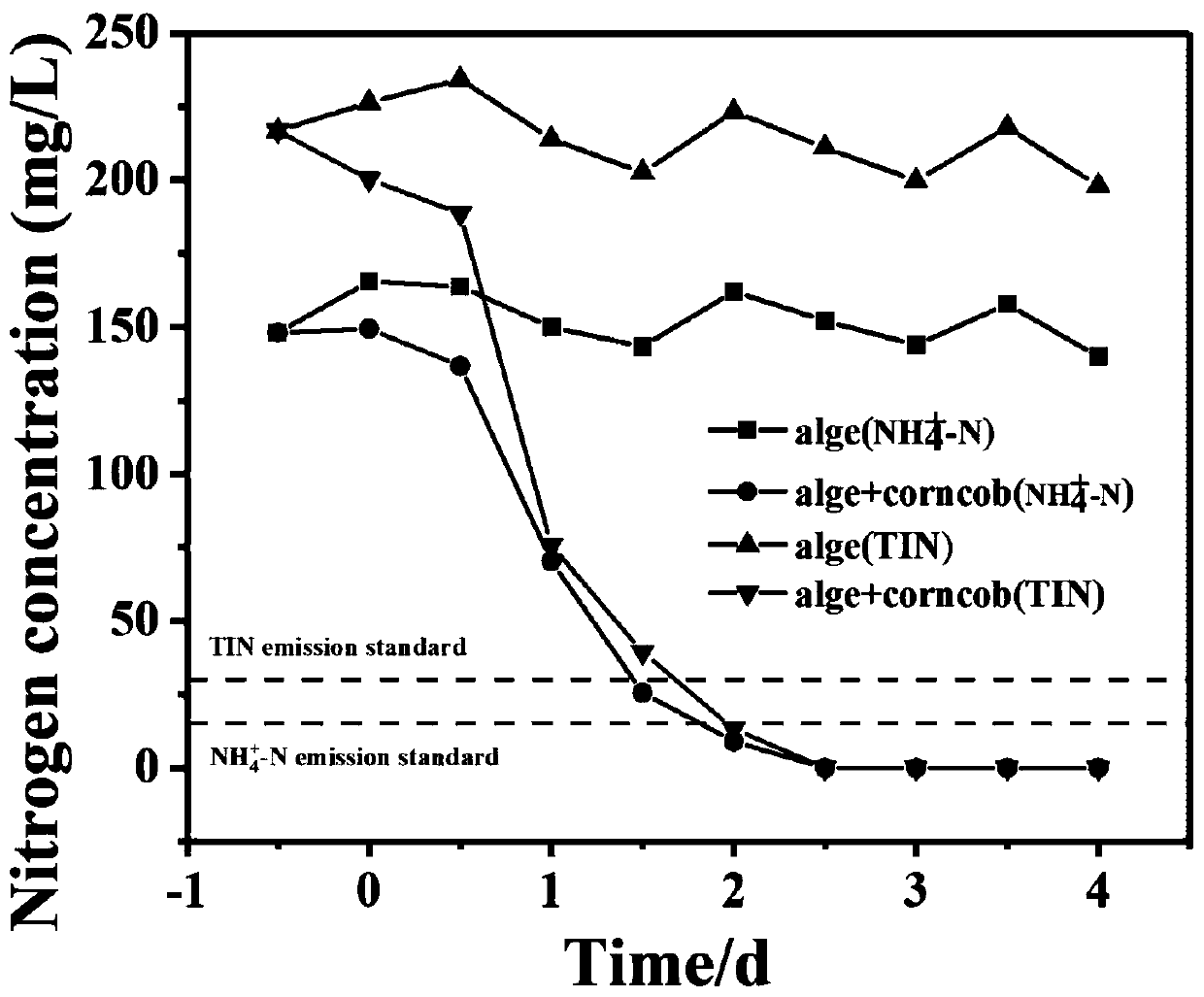

[0051]Two groups of experiments, the first group of experiments only added the screened specific microalgae (Scenedes), and the second group added corn cob carrier (corncob) while adding Scenedesmus. The initial algae density of the experiment was 1g / L, and the amount of corncob carrier added in the second group of experiments was 20g / L. figure 1 Microalgae-loaded pictures for corncobs, figure 2 is the graph of total nitrogen and ammonia nitrogen changing with time, from figure 2 It can be observed that the addition of corn cob can effectively improve the removal efficiency of ammonia nitrogen and total nitrogen, and the removal rate of total nitrogen is from 4.7 mg·L without corn cob carrier. -1 d -1 Increased to 86.7mg·L -1 d -1 , and the removal capacity of ammonia nitrogen reaches 83.3mg·L -1 d -1 .

Embodiment 2

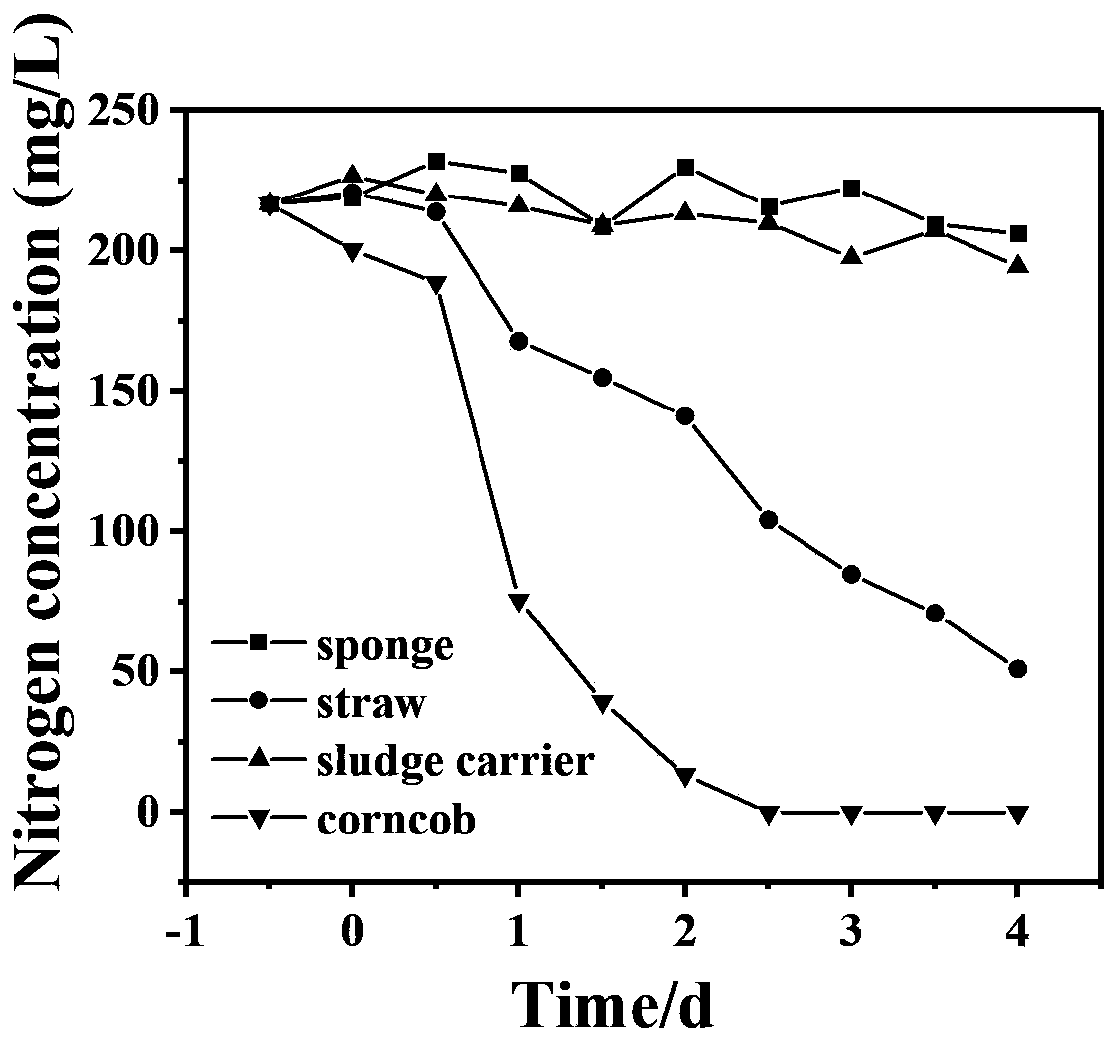

[0052] Embodiment 2: Different carrier comparative experiments

[0053] The initial algae density of the four experiments was 1.0g / L, the carrier of the first group was sponge, the carrier of the second group was straw, the carrier of the third group was a common biofilm carrier, and the carrier of the fourth group was corn core (corncob), the amount of carrier added is 20g / L, image 3 It is a graph showing the change of total nitrogen with time. Depend on image 3 It was evident that the optimal carrier was a corn cob carrier.

[0054] The average value of water quality in Example 1 and Example 2 after three days of corn-loaded microalgae treatment was compared before and after treatment, and the data are shown in Table 2. From Table 2, it can be concluded that within three days, corncob-loaded flocculation microalgae can completely denitrify rare earth mine wastewater, but the residence time of three days makes water acidification and COD exceed the standard during denitr...

Embodiment 3

[0058] After the microalgae pool reaction, although the ammonia nitrogen and total nitrogen in the purified water can reach the standard, the death and renewal of the algae metabolism and the hydrolysis of the corn cob will cause the COD of the water quality to slightly exceed the standard, and the water body will be weakly acidified. Therefore, the traditional activated sludge method is used to further treat the purified water, and the hydraulic retention time is initially optimized. Figure 4 It is the flow chart of the denitrification method of rare earth mine wastewater by loaded microalgae in Example 3. After the raw water of rare earth mine wastewater is treated with quicklime precipitation, a clarification tank is obtained, and then denitrification treatment is carried out through the microalgae pool, and then passed through the traditional active sewage. The mud method is used for post-treatment, followed by disinfection in turn to obtain effluent.

[0059] At the begi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com