Method for preparing furfural by inorganic salt-adopted composite catalysis of xylose in homogeneous system

A technology for composite catalysis of xylose and inorganic salts, which is applied in the field of inorganic salt composite catalysis of xylose to prepare furfural, preparation of xylose, and preparation of furfural by catalysis of xylose, achieving high catalytic efficiency, avoiding equipment corrosion, and high synergistic catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 1g of xylose in the mixed system of water and dimethyl sulfoxide, where the volumes of water and DMSO are 15mL respectively, and then add SnCl 4 / LiCl compound salt, the molar ratio of compound salt to xylose is 0.5:1, wherein SnCl 4 and LiCl are 0.93g and 0.03g respectively, SnCl 4 The mole fraction of the total amount of inorganic salts is 0.8. React at 130°C for 360min.

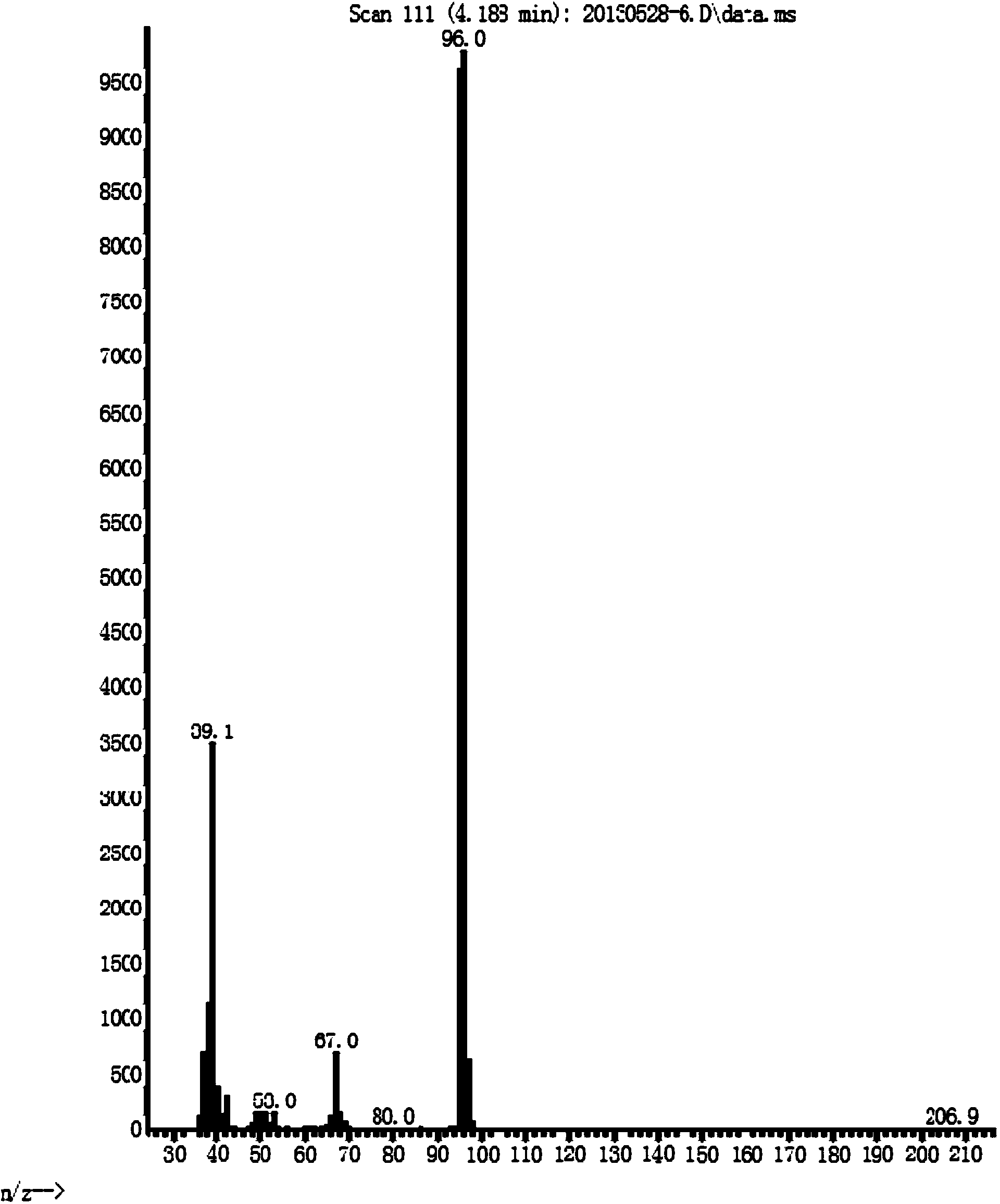

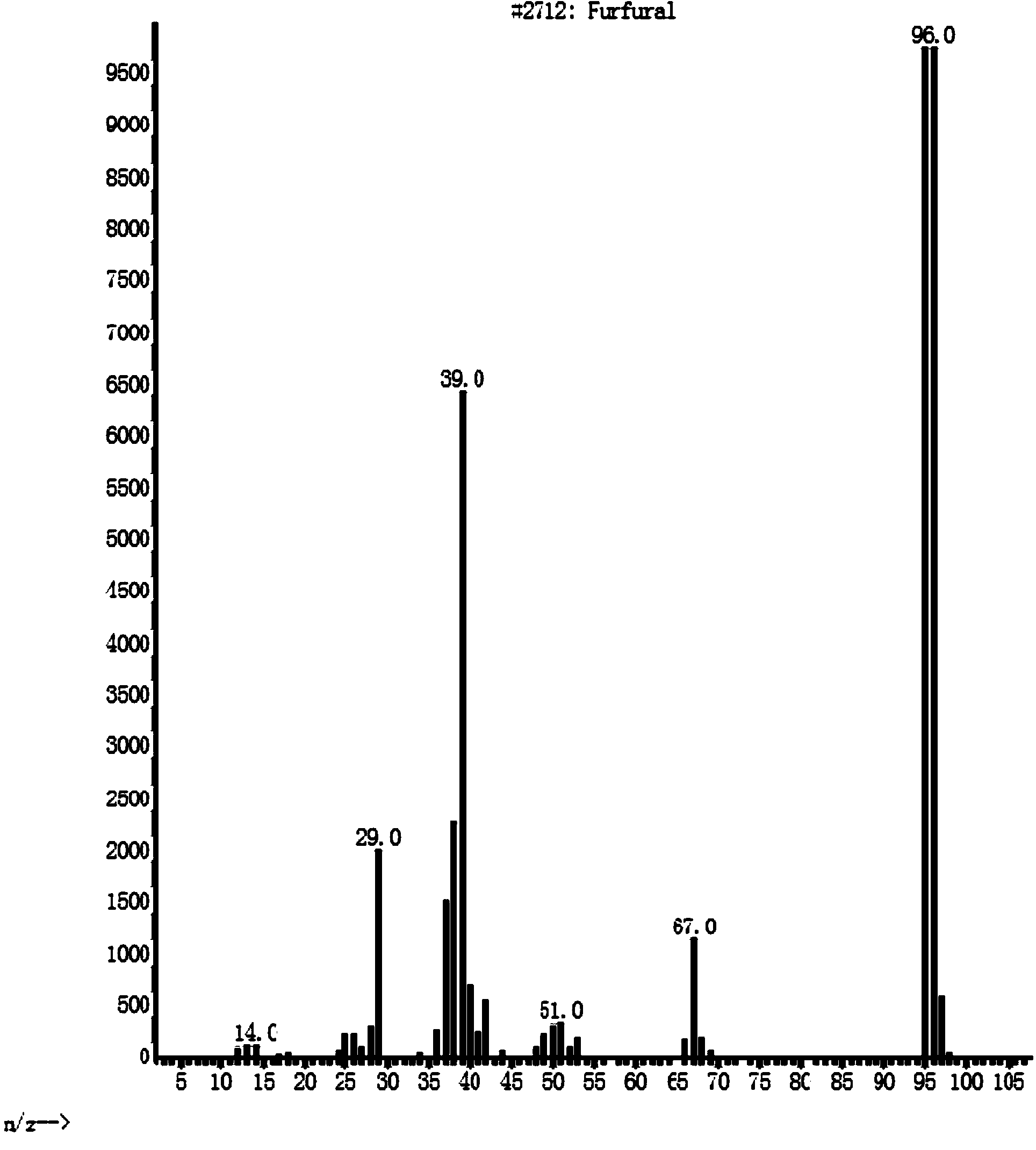

[0024] (2) After the reaction, cool naturally, and extract the reaction solution with a large amount of dichloromethane multiple times, and add a small amount of water to wash it several times to remove DMSO in the organic phase. After the organic phase obtained by extraction was washed with saturated brine, dichloromethane was distilled from the organic phase under normal pressure and the temperature was controlled at 40° C. to obtain furfural. figure 1 , 2 The figure obtained by testing the catalytic product with a gas chromatography-mass spectrometer, wherein figure 1 is the mas...

Embodiment 2

[0030] (1) Dissolve 1g of xylose in the mixed system of water and dimethyl sulfoxide (the volume of water is 12.0mL and the volume of DMSO is 8.0mL), and then add the compound inorganic salt AlCl 3 / KCl, the molar ratio of compound salt to xylose is 0.25:1; AlCl 3 The masses of AlCl and KCl are 0.20g and 0.06g respectively, AlCl 3 The mole fraction of the total amount of inorganic salts is 0.5. React at 160°C for 30 minutes.

[0031] (2) After the reaction, cool naturally, and extract the reaction solution with a large amount of dichloromethane multiple times, and add a small amount of water to wash it several times to remove DMSO in the organic phase. After the organic phase obtained by extraction was washed with saturated brine, dichloromethane was distilled from the organic phase under normal pressure and the temperature was controlled at 41° C. to obtain furfural. Judging that reaction product is furfural according to gas chromatography-mass spectrometry measurement res...

Embodiment 3

[0034] (1) Dissolve 1g of xylose in the mixed system of water and dimethyl sulfoxide (the volume of water is 3.33mL and the volume of DMSO is 6.66mL), then add CrCl 3 / NaCl compound salt, the molar ratio of compound salt to xylose is 1:1; CrCl 3 The masses of NaCl and NaCl are 0.36g and 0.31g respectively, CrCl 3 The mole fraction of the total amount of inorganic salts is 0.2. React at 110°C for 600min.

[0035] (2) After the reaction, cool naturally, and extract the reaction solution with a large amount of dichloromethane multiple times, and add a small amount of water to wash it several times to remove DMSO in the organic phase. After the organic phase obtained by extraction was washed with saturated brine, dichloromethane was distilled from the organic phase under normal pressure and controlled at a temperature of 39° C. to obtain furfural. Judging that reaction product is furfural according to gas chromatography-mass spectrometry measurement result, method is with embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com