Technology for treating and purifying copper electrolyte by vortex electrolysis

A swirl electrolysis and technical processing technology, which is applied in the direction of photographic technology, electrolysis process, electrolysis components, etc., can solve the problems of low current density and current efficiency, large amount of black copper plates and black copper slag, poor selectivity of metal precipitation, etc. , to achieve the effect of reducing the amount of black copper plates and black copper slag, mobilizing funds and increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

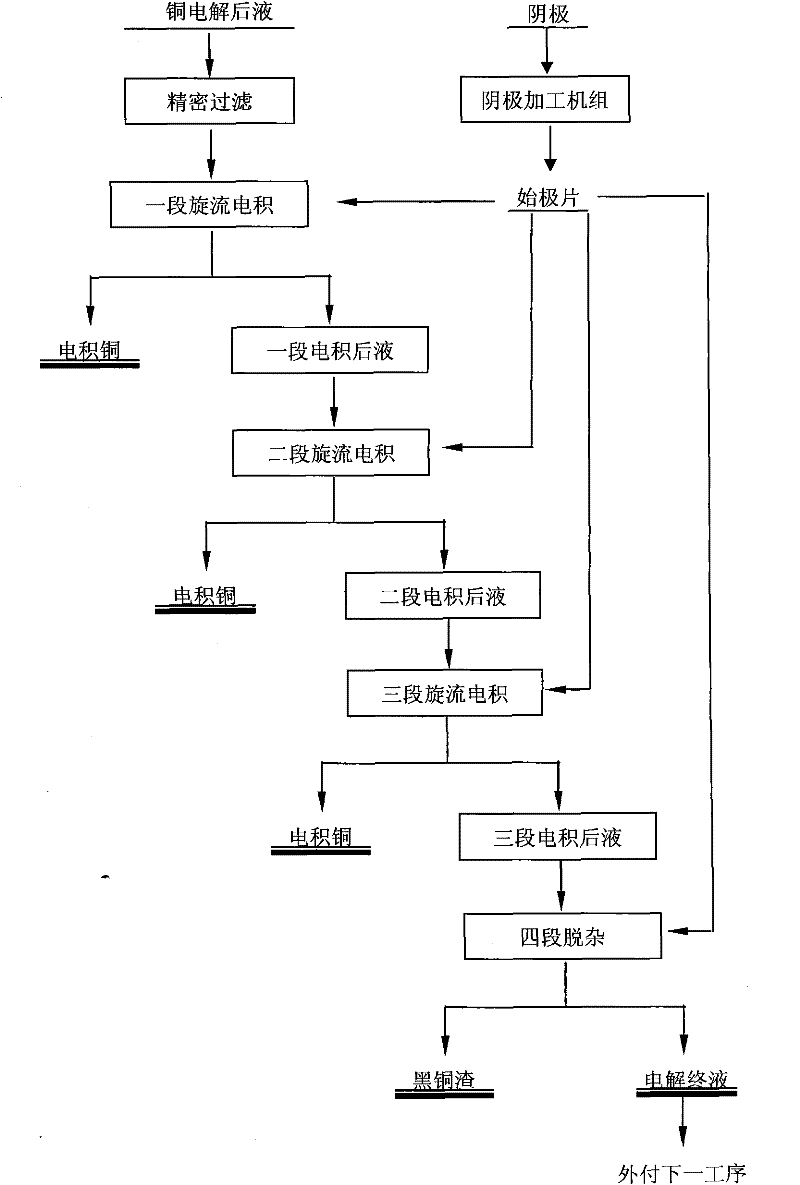

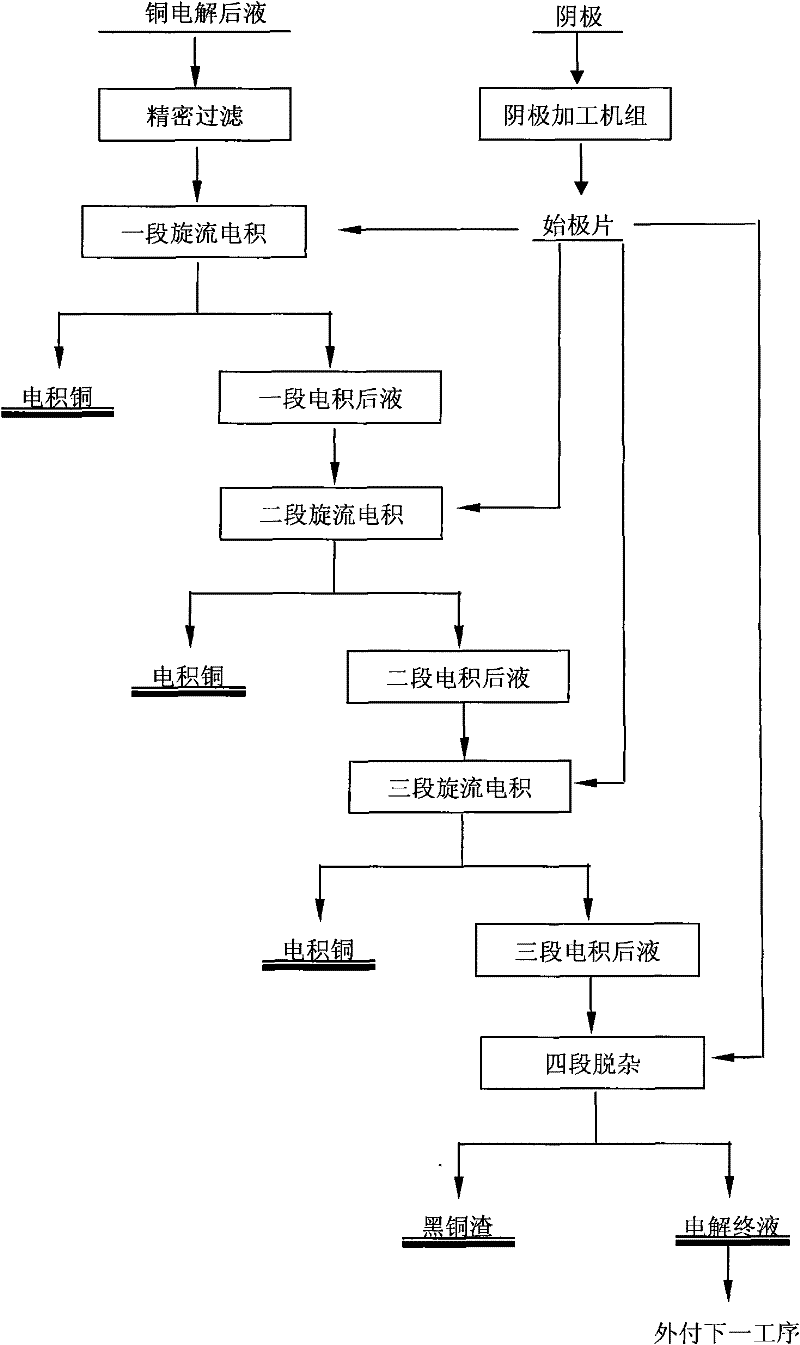

[0018] refer to figure 1 , the specific implementation method adopts the following technical scheme: its treatment process is: 1. The copper electrolyte that needs to be purified is filtered through precision; 2. Enter the swirl electrolysis system to produce standard cathode copper; 3. After three sections of swirl electrolysis Finally, when the copper content in the solution is 2-4g / L, the solution enters the impurity removal stage of the swirling electrolytic powder; 4. The powder swirling electrolytic cell removes arsenic, antimony, bismuth and other impurities to meet the purification requirements; 5. After pressing After filtering, the filter cake forms a small amount of black copper slag with low copper content, and the filtrate enters the next process.

[0019] The specific operation steps of this embodiment are:

[0020] 1. Precision filtration: Due to the copper electrolyte that needs to be purified, some solid fine particles such as floating anode slime and some so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com