High PH treatment of pulp in a bleach sequence to produce pulp having low D.P. and low copper number for use in lyocell manufacture

a technology of lyocell and high ph treatment, which is applied in the direction of pulping with inorganic bases, non-fibrous pulp addition, papermaking, etc., can solve the problems of high purification cost of “alpha pulp” and unsuitable for use in lyocell manufacturing, and achieve high ph and reduce the degree of polymerization of pulp. , the effect of reducing the degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

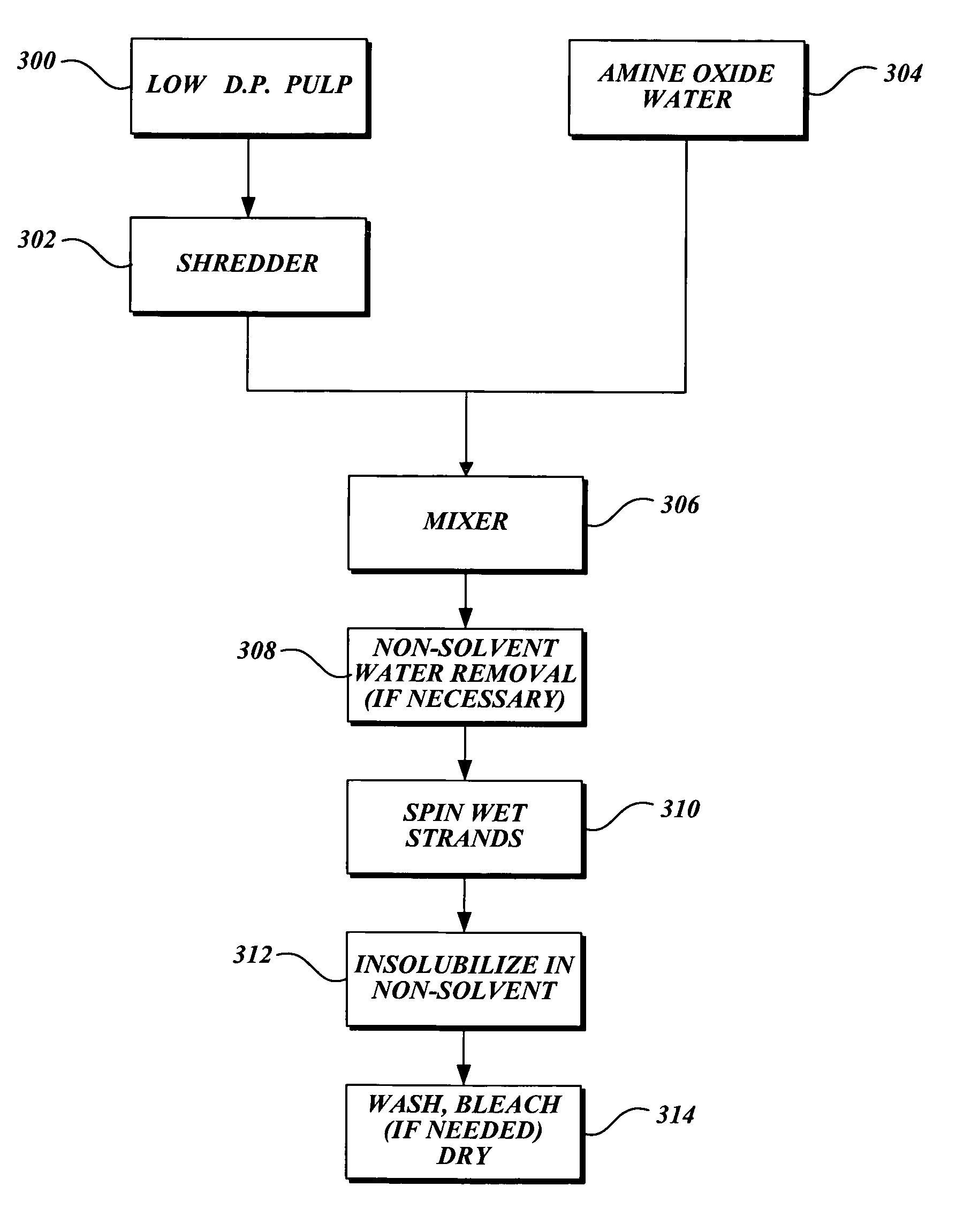

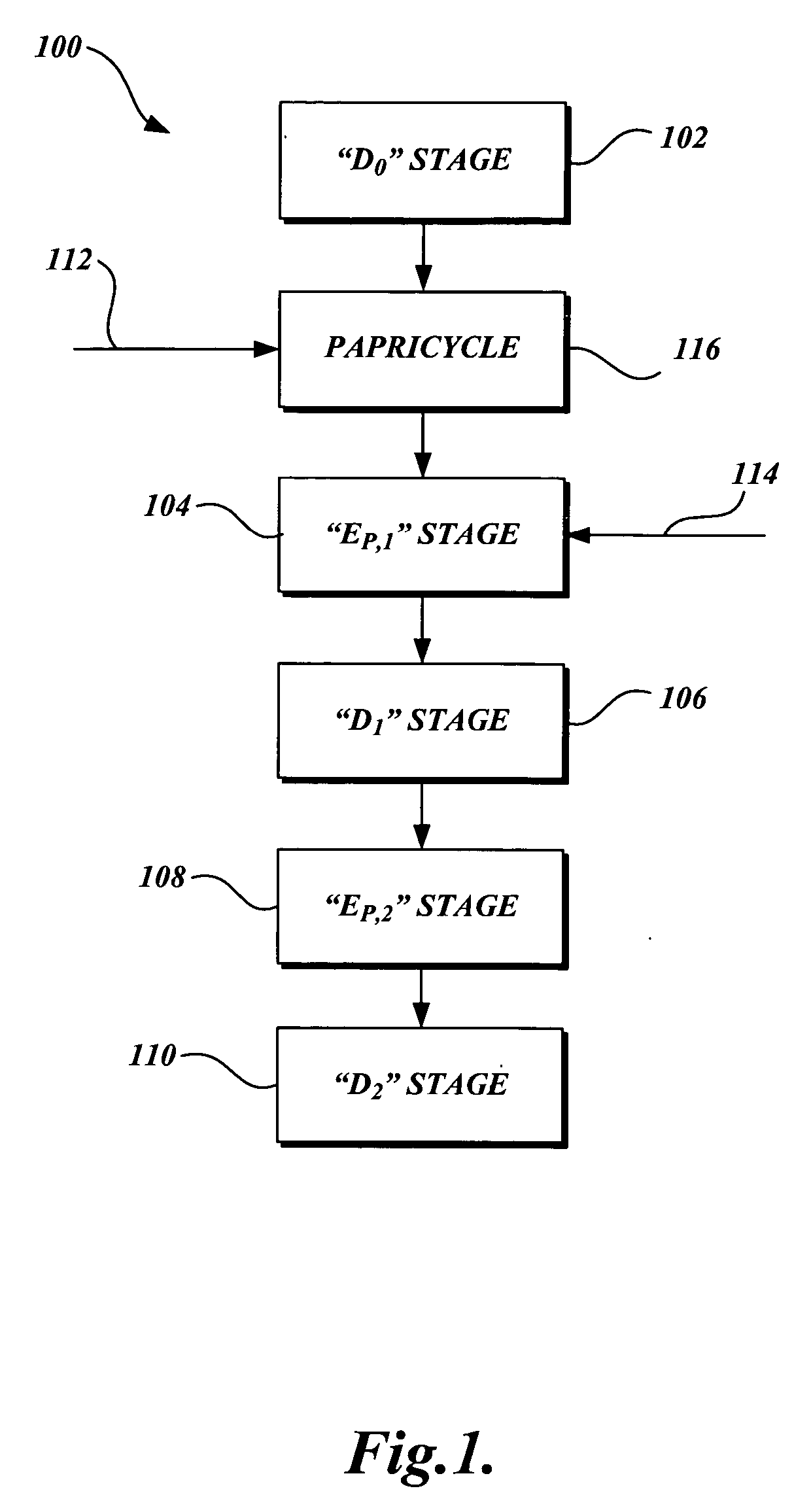

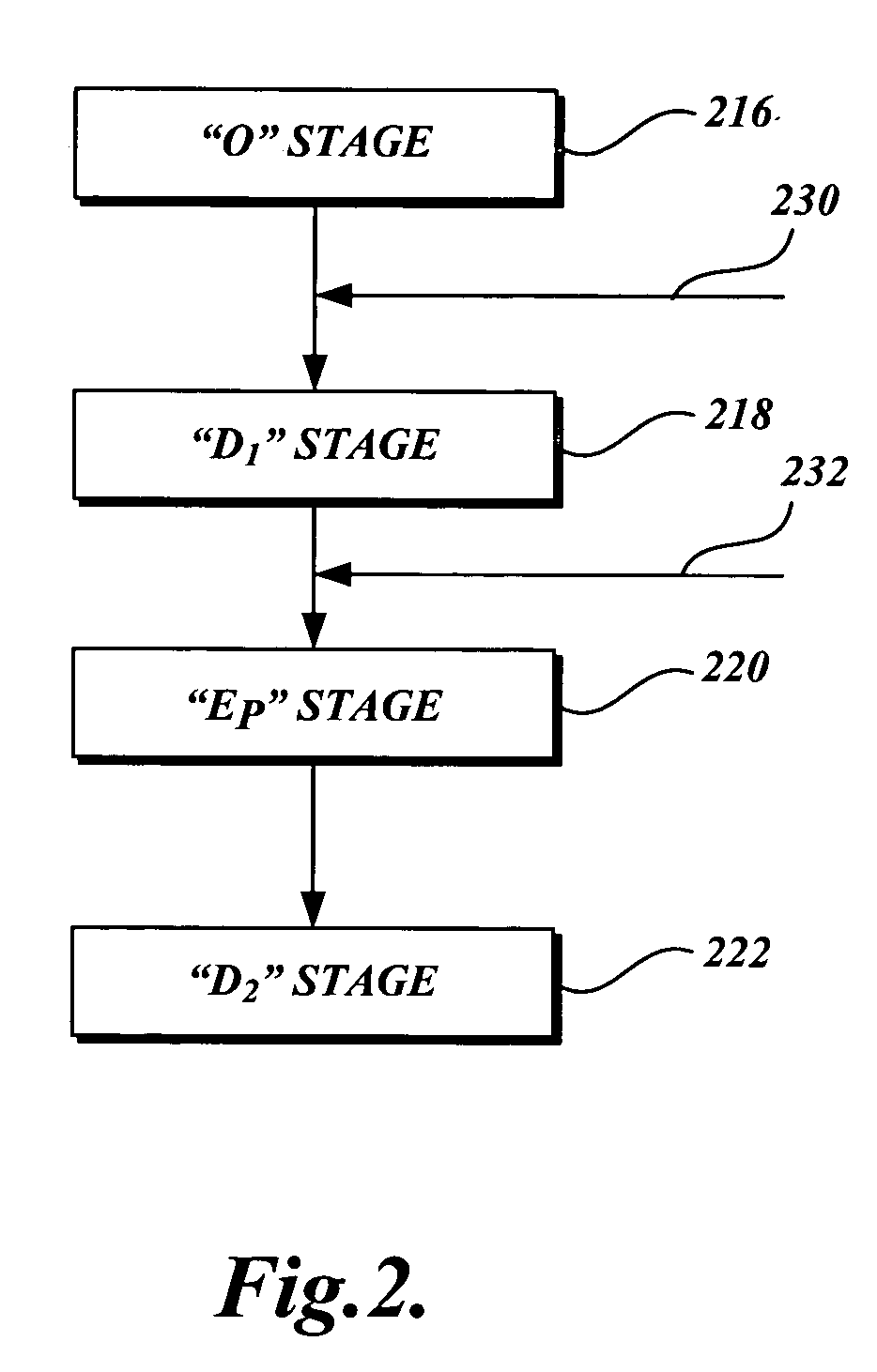

Method used

Image

Examples

example a

Reduction of Degree of Polymerization at High PH with a Catalyst

[0046] Once dried pulp (NB416 fluff pulp available from the Weyerhaeuser Co. of Federal Way, Wash.) now having a consistency of 10% was mixed with 1.5% NaOH (based on pulp weight) and 1.5% H2O2 (based on pulp weight) in a container and bleached at 90° C. for one hour in a lab. A catalyst was added to increase the reduction of degree of polymerization of cellulose. A control sample has a degree of polymerization of 1310. The results are summarized in Table 1.

TABLE 1CATALYSTS FOR H2O2 BLEACHING OF PULPCatalyst inD.P. (postD.P. dropPulpCatalystwater (ppm)treatment)(%)NB416-dryNone1310NB416-dryWater / H2O2 / NaOHnone116511NB416-dryFeCl2.4H2O13.6101523NB416-dryFeCl3.6H2O11.289432NB416-dryMnCl2.3H2O13.512415NB416-dryMnCl211.212425

example b

Reduction of Degree of Polymerization at High PH with a Catalyst

[0047] Never dried pulp from the Weyerhaeuser Company's Kamloops mill from the D1 stage having a consistency of 10% was mixed with NaOH and H2O2 in a container and bleached 90° C. for one hour in a lab. Sodium hydroxide was added at the rate of 1.5%, and hydrogen peroxide was added at the rate of 1.5%, where percent is based on the weight of the pulp, unless otherwise indicated. A catalyst was added to catalyze the reduction of degree of polymerization of cellulose. The pH was greater than 8. A control sample has a degree of polymerization of 939. Some of the samples were washed with deionized (DI) water prior to bleaching. The results are summarized in Table 2.

TABLE 2CATALYST EFFECTIVENESS FORBLEACHING OF MILL SAMPLESCatalystD.P. / copperin waternumber (postD.P. dropPulpCatalyst(ppm)treatment)(%)Kamloops D1None939Kamloops D1Water / H2O2 / NaOH078117Kamloops D1Double H2O20698 / 0.826Kamloops D1FeCl3.6H2O13694 / 0.826Kamloops D...

example c

Reduction of Degree of Polymerization at High PH with a Catalyst

[0049] Never dried pulp (centrifuged Kamloops D1 pulp) having a consistency of 10% was mixed with 1.0% NaOH (based on pulp weight) and 2.0% H2O2 (based on pulp weight) in a container and bleached at 88° C. for one hour in a lab. The pH was greater than 8. A catalyst was added to increase the reduction of degree of polymerization of cellulose. A control sample has a degree of polymerization of 939. The transition metals Ca and Mg that are normally present in the mill are simulated by adding water containing low concentrations of these elemental transition metals. The results are summarized in Table 3.

TABLE 3MILL WATER IMPACT ON BLEACHINGD.P. / copperCatalystnumberCu / Fein water(post-in finalPulpCatalyst(ppm)treatment)CommentproductKamloops D1None939Kamloops D1Water / H2O2 / NaOH07891.0% H2O2 on10pulpKamloops D1Water / H2O2 / NaOH0711 / 0.86 / 4Kamloops D1Water / H2O2 / NaOHWater*93913 ppm Ca / 3 ppm Mg / 0.3 ppm Mn inwaterKamloops D1CuSO365...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com