Copper-containing waste etching solution treatment method and etching solution regeneration method

A treatment method and a waste liquid treatment technology, which are applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of inability to recycle hydrogen peroxide and chemical etchant, and the inability to effectively recycle chemical etchant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

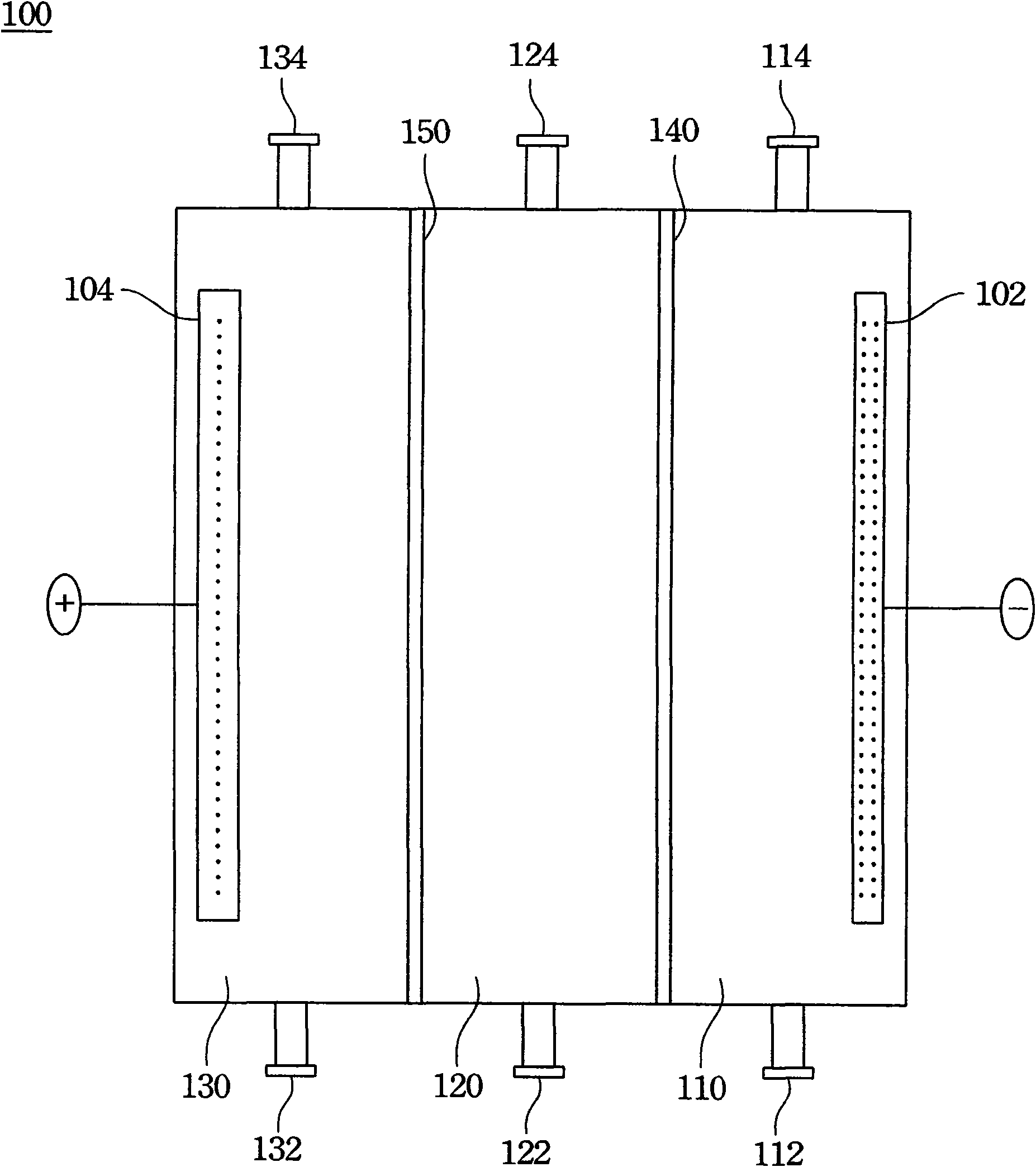

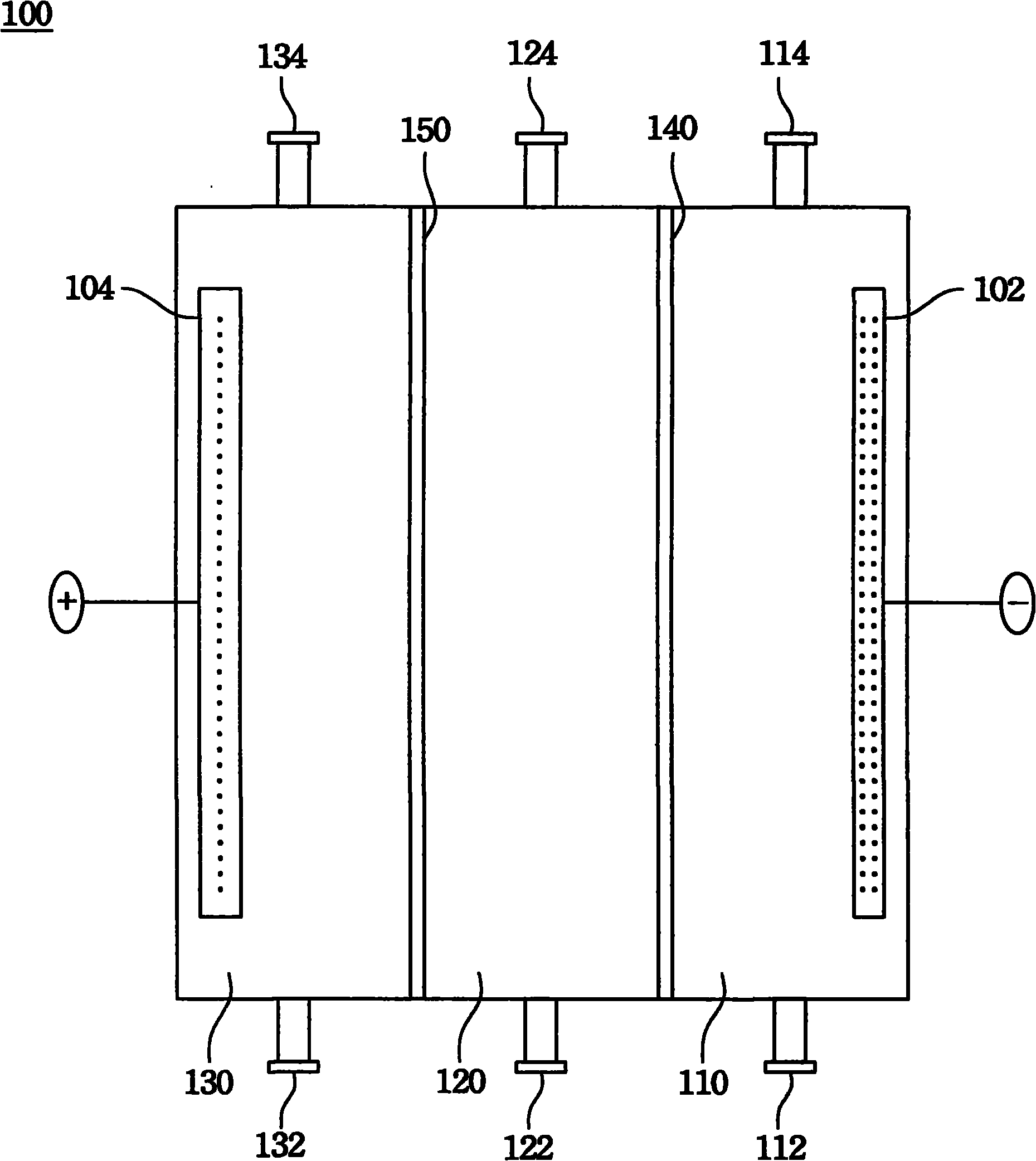

[0051] Embodiments and specific examples of the present invention are described below with reference to the accompanying drawings, in which like reference numerals refer to like parts throughout.

[0052] In various embodiments of the present invention, a treatment method for copper-containing etching waste liquid is proposed. Generally speaking, the waste copper-containing etching solution contains at least copper ions, ammonium ions, hydrogen peroxide and other chemical substances contained in the original etching solution. The treatment method proposed by the present invention can not only obtain copper with economic value, but also various products produced in the reaction process also have the value of recycling and reuse. In addition, the above treatment method can better retain most of the chemical composition of the original etching solution in the waste etching solution, so that it can be recycled and used to avoid unnecessary waste.

[0053] One embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com