High-sulfur cobalt copper ore treatment process with low cost and high leaching rate

A technology of treatment process and leaching rate, applied in the field of treatment technology of high-sulfur cobalt copper ore, can solve the problems of equipment corrosion, high equipment requirements, long leaching period of bioleaching method, etc., and achieve the effect of low cost and low energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

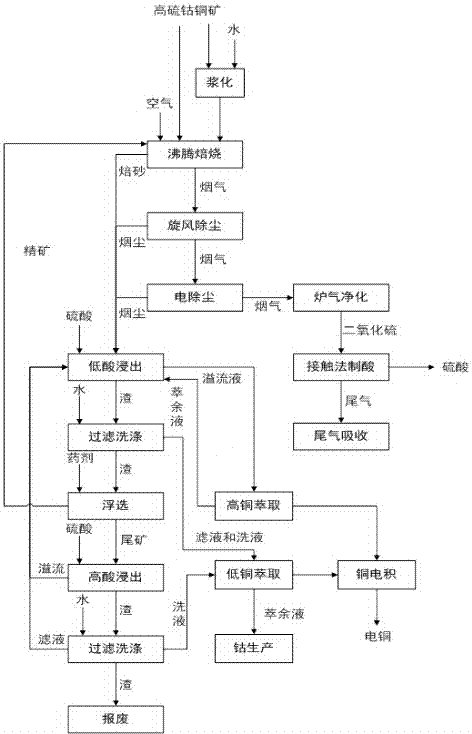

Method used

Image

Examples

Embodiment 1

[0021] The high-sulfur cobalt-copper ore slurry (Co7.5%, Cu17.66%, Fe7.55%, S25.33%) with a solid content of 60% is transported into a 32㎡ conical fluidized furnace at a speed of 13t / h, and oxygen-enriched air is blown 150m³ / min, oxygen concentration 26%, boiling roasting at 520°C, roasting time 14.5h, air velocity 0.23 m / s, air-to-material ratio 1.15m³ / kg; flue gas enters cyclone dust collector for dust removal, flue gas oxygen concentration 8%, sulfur dioxide The concentration is 5.5%, and then go through the electrostatic precipitator for dust removal, and the flue gas furnace gas purification process is followed by contact with legal acid; the calcined sand at the outlet of the fluidized fluidized furnace is mixed with the smoke and dust produced by the cyclone dust collector and the electrostatic precipitator, and the mixture goes to the low acid leaching stirring tank, and the leaching pH 2. The leaching temperature is 70°C, the leaching time is 2 hours, and the liquid-so...

Embodiment 2

[0024] High-sulfur cobalt-copper ore slurry (Co7.7%, Cu17.32%, Fe8.55%, S26.31%) containing 50% solids is transported into a 32㎡ conical fluidized furnace at a speed of 14t / h, and oxygen-enriched air is blown 150 m³ / min, oxygen concentration 26%, boiling roasting at 600°C, roasting time 16h, air velocity 0.25 m / s, air-to-material ratio 1.29 m³ / kg; flue gas enters cyclone dust collector for dust removal, flue gas oxygen concentration 8.5%, sulfur dioxide Concentration of 5.14%, and then go through the electrostatic precipitator for dust removal, flue gas furnace gas purification process and then contact legal acid; the calcined sand at the outlet of the fluidized fluidized furnace is mixed with the smoke and dust produced by the cyclone dust collector and the electrostatic precipitator, and the mixture goes to the low acid leaching stirring tank, and the leaching pH 2. The leaching temperature is 75°C, the leaching time is 2 hours, and the liquid-solid ratio is 12:1. After being...

Embodiment 3

[0027] The high-sulfur cobalt-copper ore slurry (Co7.6%, Cu16.89%, Fe7.85%, S25.79%) with a solid content of 70% is transported into a 32㎡ conical fluidized furnace at a speed of 13t / h, and oxygen-enriched air is blown 150 m³ / min, oxygen concentration 26%, boiling roasting at 680°C, roasting time 12.5h, air velocity 0.27 m / s, air-material ratio 1m³ / kg; flue gas enters cyclone dust collector for dust removal, flue gas oxygen concentration 7.5%, sulfur dioxide Concentration of 6.5%, and then go through the electrostatic precipitator for dust removal, flue gas furnace gas purification process and then contact with legal acid; the calcined sand at the outlet of the fluidized fluidized furnace is mixed with the smoke and dust produced by the cyclone dust collector and the electrostatic precipitator, and the mixture goes to the low-acid leaching stirring tank, and the leaching pH 1.5, leaching temperature 80°C, leaching time 2h, liquid-solid ratio 15:1, after being thickened by a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com