Method for improving precise control of refining worker over molten steel temperature

A technology of molten steel temperature and molten steel, applied in the direction of improving process efficiency, etc., can solve the problems of large temperature drop fluctuations, affecting temperature control effect, high temperature continuous casting speed reduction, etc., to improve temperature control level, improve control pass rate, and ensure continuous casting The effect of constant casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

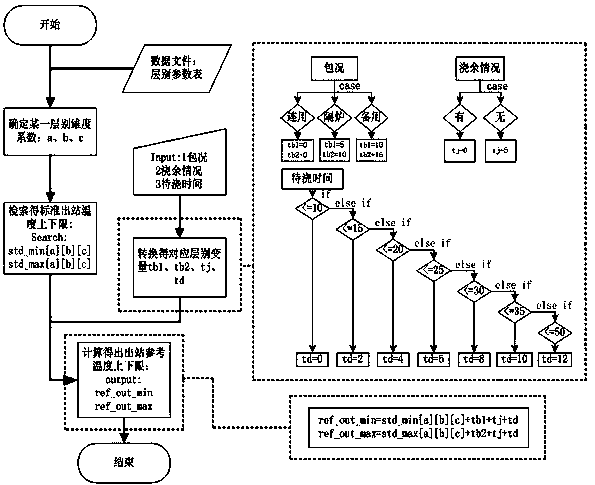

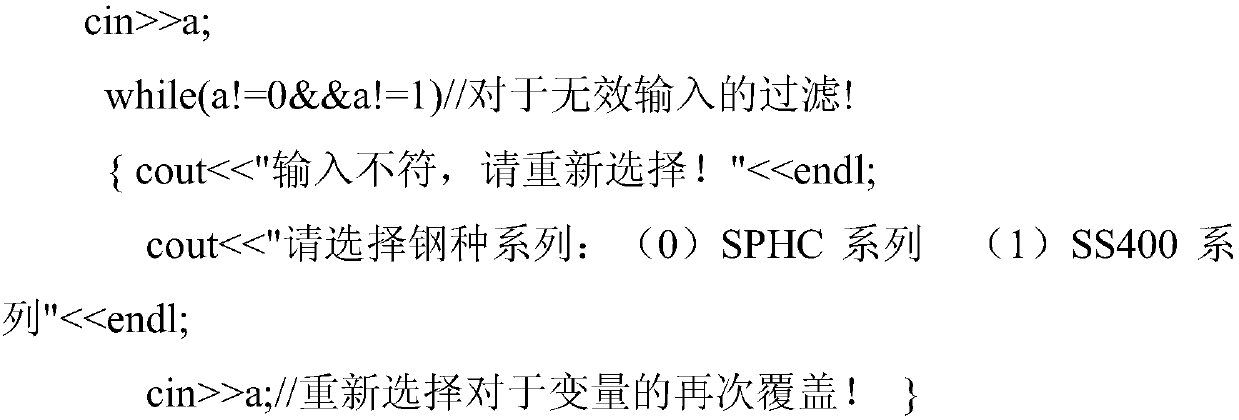

[0011] A method to improve the precision control of molten steel temperature by refiners, through the automatic temperature calculation model to realize the automatic calculation of the exit temperature of LF refined molten steel; the establishment process of the model: according to the three levels of steel type, continuous casting machine and continuous casting Based on the upper and lower limits of the standard out-of-station temperature, combined with the refiner’s input of three sets of parameters according to the actual production situation, the condition of the ladle, the recovery of pouring waste and the waiting time of the molten steel, they are converted into variables of the corresponding layer, and finally the LF finish is calculated. The upper and lower limits of the outgoing temperature of molten steel; refiners only need to perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com