Material preparation process for preparing dissolving pulp by modifying bleached needle leave wood and broadleaf wood composite pulp

A technology for compounding pulp and hardwood is applied in the field of viscose chemical fiber raw material-pulp preparation. Good control and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

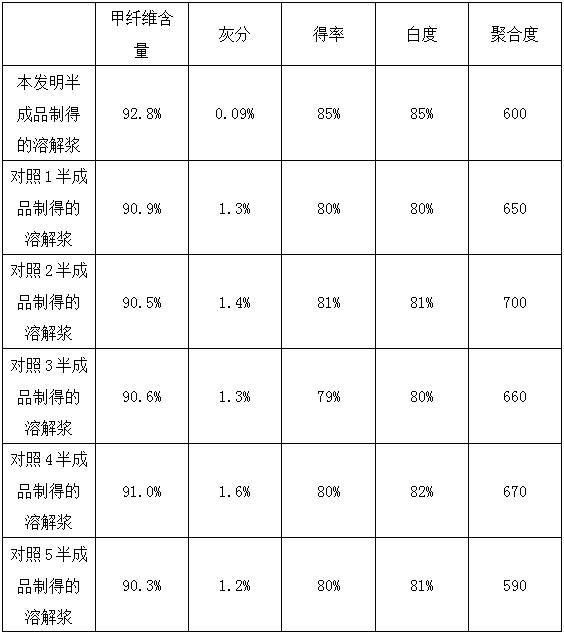

Examples

Embodiment 1

[0060] A material preparation process for preparing dissolving pulp by modifying bleached coniferous wood and hardwood composite pulp, comprising the following process steps:

[0061] A. Raw material preparation

[0062] According to the ratio of the total weight of bleached softwood pulp and bleached hardwood pulp to the volume of the digester: 100kg: 1m 3 Raw material preparation, select bleached softwood pulp and bleached hardwood pulp;

[0063] B. Dispersion and pulping

[0064] Bleached softwood pulp and bleached hardwood pulp are dispersed and processed into pulp boards, and then bleached softwood pulp boards and bleached hardwood pulp boards are mixed with sodium hydroxide solution for pulping to obtain bleached softwood pulp and bleached hardwood pulp. The mixture of paper pulp and sodium hydroxide solution is the pulp porridge, and the next step of impregnation treatment is carried out. The pulp concentration of the pulp porridge obtained through the pulping treatme...

Embodiment 2

[0073] A material preparation process for preparing dissolving pulp by modifying bleached coniferous wood and hardwood composite pulp, comprising the following process steps:

[0074] A. Raw material preparation

[0075] According to the ratio of the total weight of bleached softwood pulp and bleached hardwood pulp to the volume of the digester: 250kg: 1m 3 Raw material preparation, select bleached softwood pulp and bleached hardwood pulp;

[0076] B. Dispersion and pulping

[0077] Bleached softwood pulp and bleached hardwood pulp are dispersed and processed into pulp boards, and then bleached softwood pulp boards and bleached hardwood pulp boards are mixed with sodium hydroxide solution for pulping to obtain bleached softwood pulp and bleached hardwood pulp. The mixture of paper pulp and sodium hydroxide solution is the pulp porridge, and the next step of impregnation treatment is carried out, and the pulp concentration of the pulp porridge obtained through the pulping tre...

Embodiment 3

[0086] A material preparation process for preparing dissolving pulp by modifying bleached coniferous wood and hardwood composite pulp, comprising the following process steps:

[0087] A. Raw material preparation

[0088] According to the ratio of the total weight of bleached softwood pulp and bleached hardwood pulp to the volume of the digester: 175kg: 1m 3 Raw material preparation, select bleached softwood pulp and bleached hardwood pulp;

[0089] B. Dispersion and pulping

[0090] Bleached softwood pulp and bleached hardwood pulp are dispersed and processed into pulp boards, and then bleached softwood pulp boards and bleached hardwood pulp boards are mixed with sodium hydroxide solution for pulping to obtain bleached softwood pulp and bleached hardwood pulp. The mixture of paper pulp and sodium hydroxide solution is pulp porridge, and then the next step of impregnation treatment, the pulp concentration of the pulp porridge obtained through pulping treatment is 4%;

[0091...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com