Double-layer coiled tube sand pumping device and double-layer coiled tube sand pumping technology

A oil pipe and double-layer technology, which is applied in the field of double-layer coiled tubing sand pumping devices, can solve the problems of formation damage, limited sand discharge efficiency, easy sand deposition, etc., and achieve small formation damage, high sand discharge efficiency, and high sand discharge efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

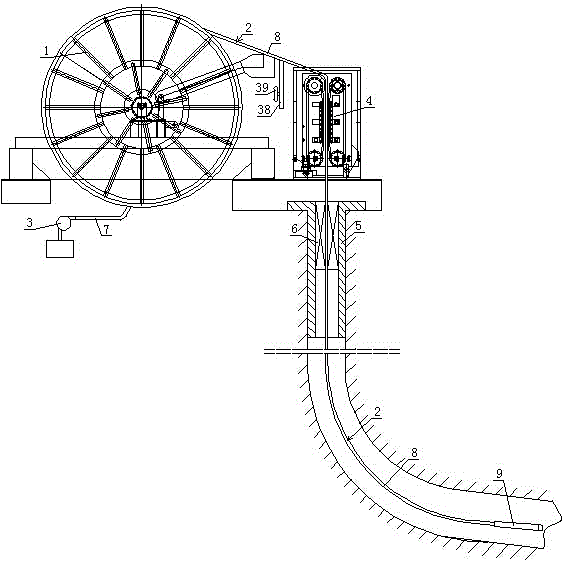

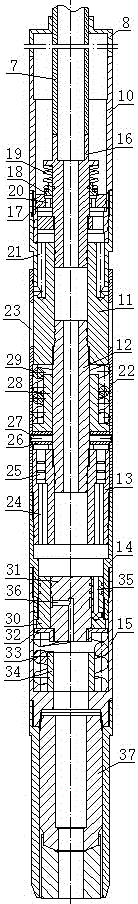

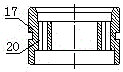

[0025] Such as Figure 1 to Figure 11 As shown, the double-layer coiled tubing sand pumping device of the embodiment of the present invention includes a coiled tubing drum 1, a motor and a reducer (not shown) as a driving device, a coiled tubing 2, a water pump 3, an injection head 4, and a wellhead The wellbore 5 and blowout preventer 6; the coiled tubing 2 includes an inner pipe 7 and an outer pipe 8, an annular space is formed between the inner pipe 7 and the outer pipe 8, and the rear end of the annular space is closed by the outer pipe 8 covering the inner pipe 7, The front end of the coiled tubing 2 is provided with a plugging nozzle 9, and the plugging nozzle 9 includes an upper connection pipe 10, a conduit 11, a connecting pipe 12, a transition pipe 13, a sleeve pipe 14 and a nozzle seat, each of which is provided with an inner hole and is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com