Photo-thermal shape memory functional material as well as preparation method and application thereof

A functional material and photothermal technology, applied in shading screens, building components, buildings, etc., can solve the problems of complex device process and high cost, and achieve the effect of simple preparation process, fast polymerization reaction speed and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

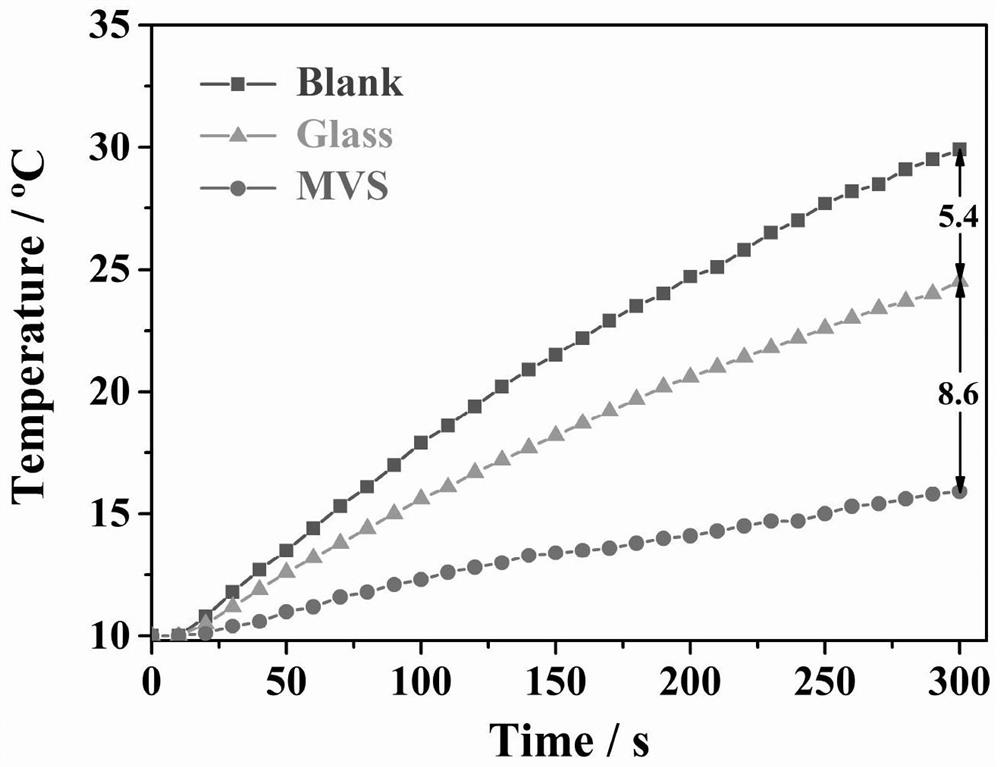

Examples

preparation example Construction

[0033] The invention provides a preparation method of a photothermal shape memory functional material, and provides a preparation method of a photothermal shape memory functional material, comprising the following steps:

[0034] Step 1, adding monomeric substances methyl methacrylate, butyl acrylate, sodium lauryl sulfate and Triton X-100 into distilled water, stirring at a speed of 100rpm-1000rpm to mix the solution evenly, and obtain a single body water;

[0035] Step 2, adding the photothermal material and 3-(methacryloyloxy)propyltrimethoxysilane into distilled water to form an aqueous solution, and stirring at a speed of 100 rpm to 1000 rpm to mix the solution evenly to obtain an aqueous solution of the photothermal material;

[0036] Step 3, adding the photothermal material aqueous solution into the monomer aqueous solution to form an emulsion, and shearing for 1 to 60 minutes with a high-speed dispersing shear;

[0037] Step 4, preparing an aqueous ammonium persulfate...

Embodiment 1

[0050]Prepare monomer solution: Take 15g of methyl methacrylate, 12g of butyl acrylate, 0.6g of sodium lauryl sulfate and 0.6g of Triton X-100, dissolve in 60ml of distilled water, and stir magnetically at room temperature;

[0051] Prepare an aqueous solution of carbon nanotubes: add 1.7g of carbon nanotube powder and 1.5g of 3-(methacryloyloxy)propyltrimethoxysilane to 10ml of distilled water, and stir at 750rpm for 30 minutes until fully dissolved Finally, it is added to the monomer solution to form an emulsion, which is sheared by a high-speed shear for 5 minutes;

[0052] Preparation of ammonium persulfate solution: 0.12 g of ammonium persulfate was dissolved in 15 ml of distilled water;

[0053] Take a quarter of the emulsion and a quarter of the ammonium persulfate solution in a four-necked flask, and start pre-polymerization for 30 minutes at a water bath temperature of 80°C and a mechanical stirring of 400rpm;

[0054] After the remaining emulsion was sheared at high...

Embodiment 2

[0058] Prepare monomer solution: take 30g of methyl methacrylate, 20g of butyl acrylate, 1.5g of sodium lauryl sulfate and 1.8g of Triton X-100, dissolve in 100ml of distilled water, and stir magnetically at room temperature;

[0059] Prepare an aqueous solution of vanadium dioxide: 5g of vanadium dioxide powder and 2.5g of 3-(methacryloyloxy)propyltrimethoxysilane are added to 15ml of distilled water, and stirred at 1000rpm for 60 minutes, until fully dissolved , adding it to the monomer solution to form an emulsion, which is sheared by a high-speed shear for 15 minutes;

[0060] Preparation of ammonium persulfate solution: 0.5 g of ammonium persulfate was dissolved in 30 ml of distilled water;

[0061] Take one-third of the emulsion and one-third of the ammonium persulfate solution in a four-necked flask, and start pre-polymerization for 50 minutes under the conditions of a water bath temperature of 60°C and a mechanical stirring of 600rpm;

[0062] After the remaining emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com