Method for separating and refining isobomyl acetate

A technology of isobornyl acetate and refined ester, which is applied in the field of chemical technology, can solve the problems of reducing the yield of isobornyl acetate, increasing by-products, and increasing the circulation volume, etc., so as to improve selectivity, catalyst life, and product The effect of stable quality and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

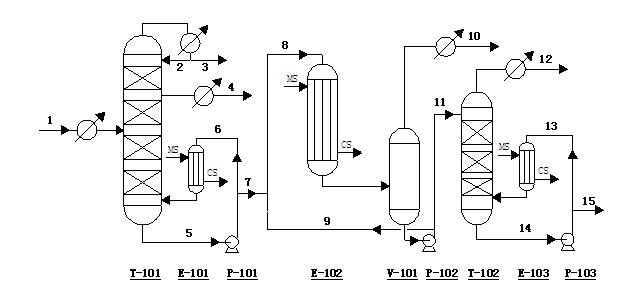

[0024] Composition in the feed crude ester (1) is water: 0.6%, acetic acid: 9.7%; Camphene: 11.5%; Isobornyl acetate: 73.6%; Miscellaneous ester: 3.6% heavy oil: 1%, crude ester rectification tower T-101 The theoretical plate number is 30 grades, the feed is at the 15th grade, the membrane acid (5) taken out from the side line is at the 8th grade, the vacuum at the top of the tower is -0.093MPa, the reflux ratio is 6, and the acid water (3 ) consists of: water: 7.6%, acetic acid 92.1%, amphene 0.3%; the membrane acid (4) extracted from the side line consists of water: 0.9%, acetic acid: 25.9%, amphene: 71.7%, isoborneol acetate Esters: 1.3%, miscellaneous esters: 0.4%; the crude ester (7) extracted from the tower kettle is composed of: isobornyl acetate: 94.1%, miscellaneous esters: 4.6%, heavy oil: 1.3%.

[0025] The crude ester in the tower kettle is sent to the whitening process, and the evaporator E-102 The vacuum degree of the evaporator is controlled at -0.095MPa, the ...

Embodiment 2

[0028] The separation device of embodiment 2 is the same as that of embodiment 1, and the only difference is that the feed composition and operating conditions have changed.

[0029] When amphene esterification conversion ratio was low, the composition in the feed crude ester (1) was water: 0.4%, acetic acid: 13.0%; Amphene: 15.4%; Isobornyl acetate: 67.4%; Miscellaneous ester: 3.0% heavy oil: 0.8%, crude ester rectification tower T-101 The vacuum at the top of the tower is-0.093MPa, and the reflux ratio is 7, and the acid water (3) produced at the top of the tower consists of: water: 4.6%, 95.2% acetic acid, 0.3% camphene; the membrane acid (4) produced by the side line ) is composed of water: 0.6%, acetic acid: 32.0%, camphene: 67.5%, and the crude ester (7) extracted from the tower kettle is composed of: isobornyl acetate: 94.7%, miscellaneous ester: 4.2%, heavy oil: 1.1% %.

[0030] The crude ester in the tower kettle is sent to the whitening process, and the evaporator ...

Embodiment 3

[0034] The crude ester enters the crude ester rectification tower T-101 , the top temperature of the rectification tower is controlled at 40°C, the vacuum at the top of the tower is controlled at -0.093MPa, the temperature of the bottom of the tower is controlled at 140°C, and the reboiler E-101 The temperature is controlled at 140°C, and the tower bottom liquid (7) is sent to the refined ester evaporator E-102 Perform whitening operation, E-102 The temperature is controlled at 130°C, E-102 The vacuum degree is controlled at -0.095MPa, from E-102The vapor-liquid mixture that comes out enters the refined ester vapor-liquid separation tank V-101 to separate, V-101 A part (11) is sent to the refined ester stripper T-102 Separation of heavy components, T-102 The temperature at the top of the tower is controlled at 130°C, and the temperature at the bottom of the tower is controlled at 140°C. T-102 The vacuum at the top of the tower is controlled at -0.098MPa.

[0035] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com