Method and system for automatically controlling textile dyeing

An automatic control and fabric dyeing technology, which is applied in textiles and papermaking, textile processing machine accessories, textile material processing, etc., can solve the problems of inability to integrate automatic material distribution system, lack of unified control, complicated processes, etc., to avoid Artificial instability, automatic control, and more stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

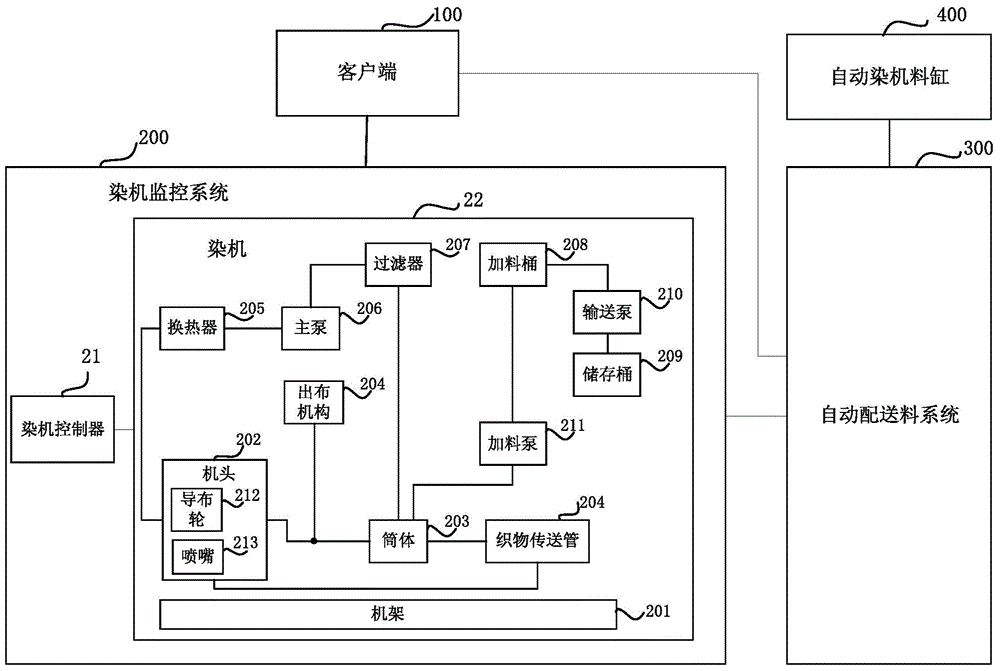

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

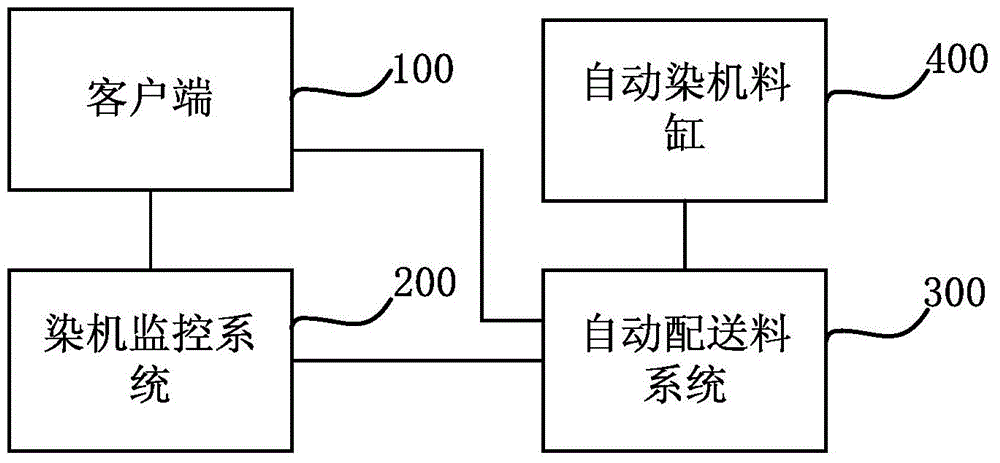

[0034] see figure 1 , is a structural schematic diagram of an embodiment of the automatic control system for fabric dyeing provided by the present invention.

[0035] The fabric dyeing automatic control system provided in this embodiment includes: a client terminal 100 , a dyeing machine monitoring system 200 , an automatic material distribution system 300 and an automatic dyeing machine tank 400 .

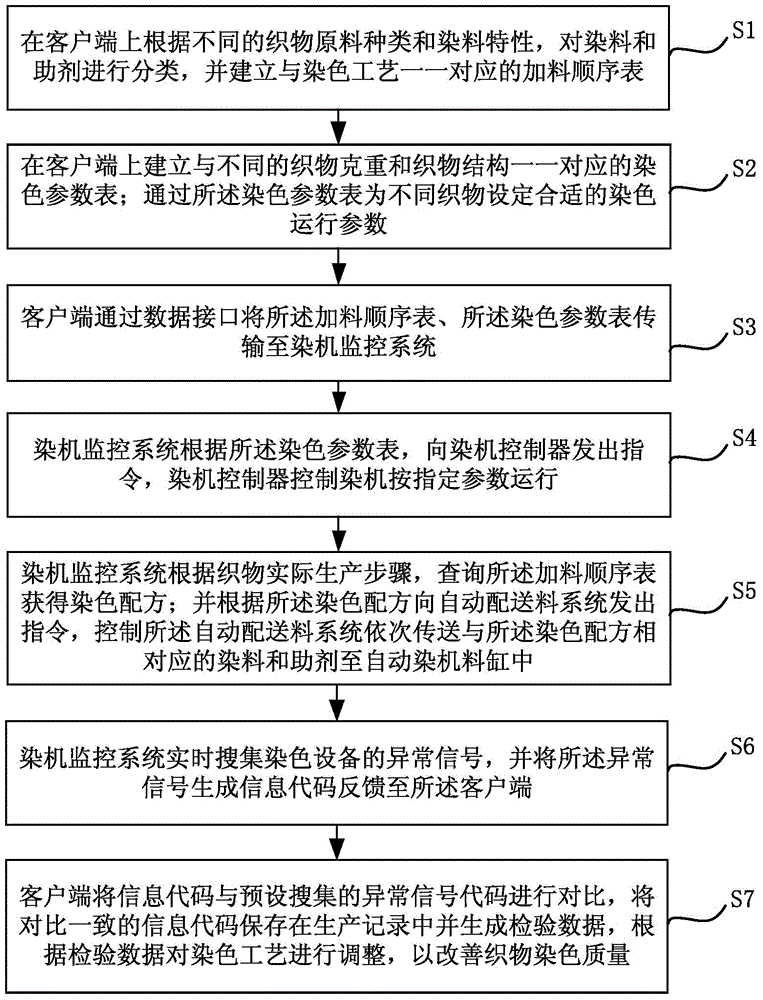

[0036] Wherein, the client 100 has a feeding sequence table corresponding to the dyeing process; the feeding sequence table sets the type of dyes and auxiliaries and the feeding sequence for each dyeing process, and automatically sets the feeding sequence number. The client 100 is also provided with a dyeing parameter table corresponding to different fabric weights and fabric str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com