Construction method for replacing steelmaking converter flue

A steelmaking converter and construction method technology, applied in the manufacture of converters, etc., can solve problems such as long cycle time, corrosion, and hidden dangers left by safe production, and achieve the effects of reduced replacement costs, simple replacement operations, and shortened construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

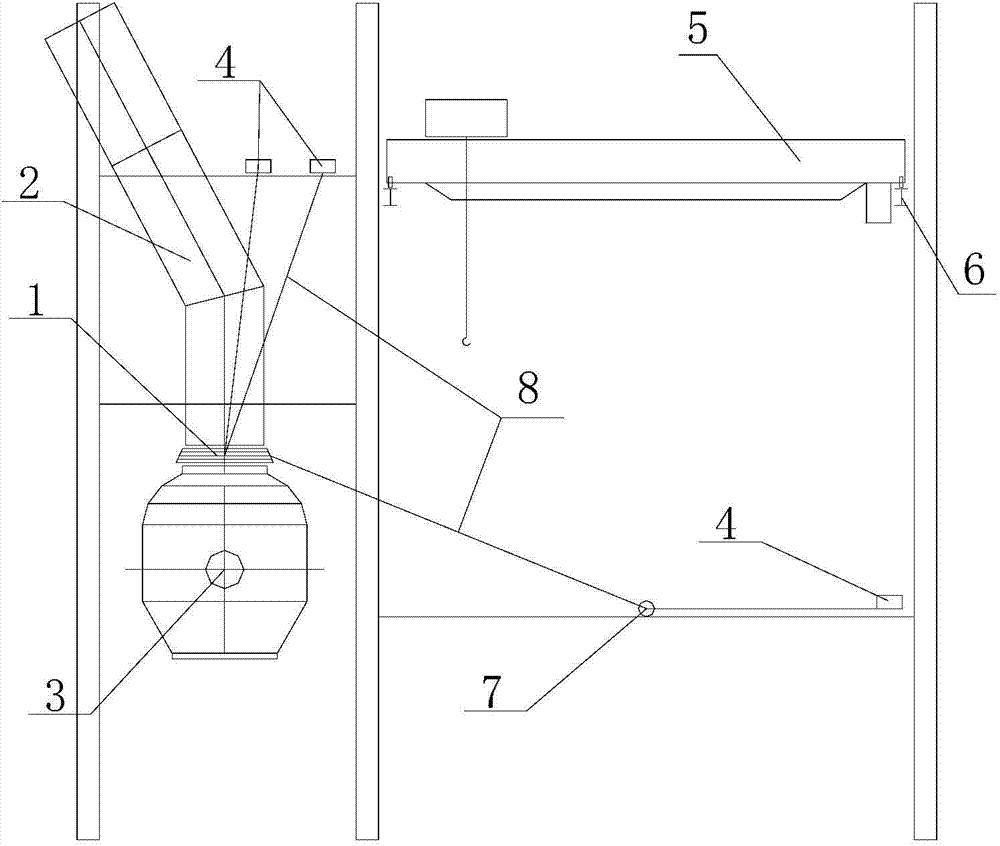

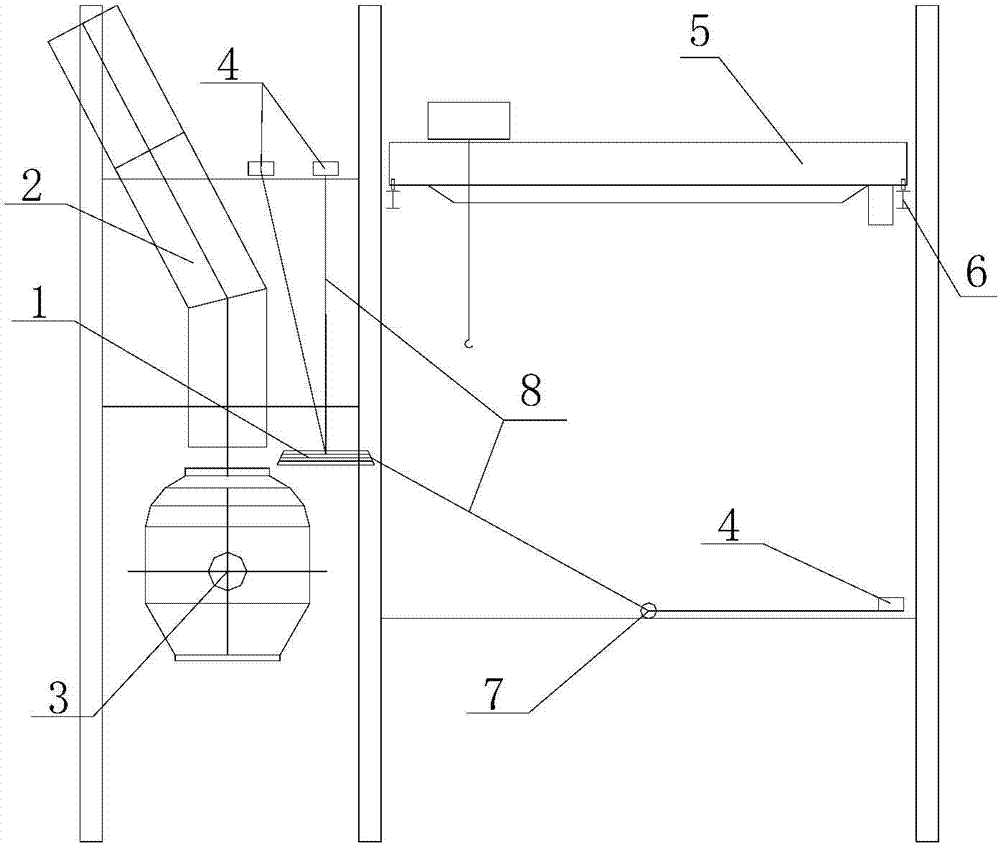

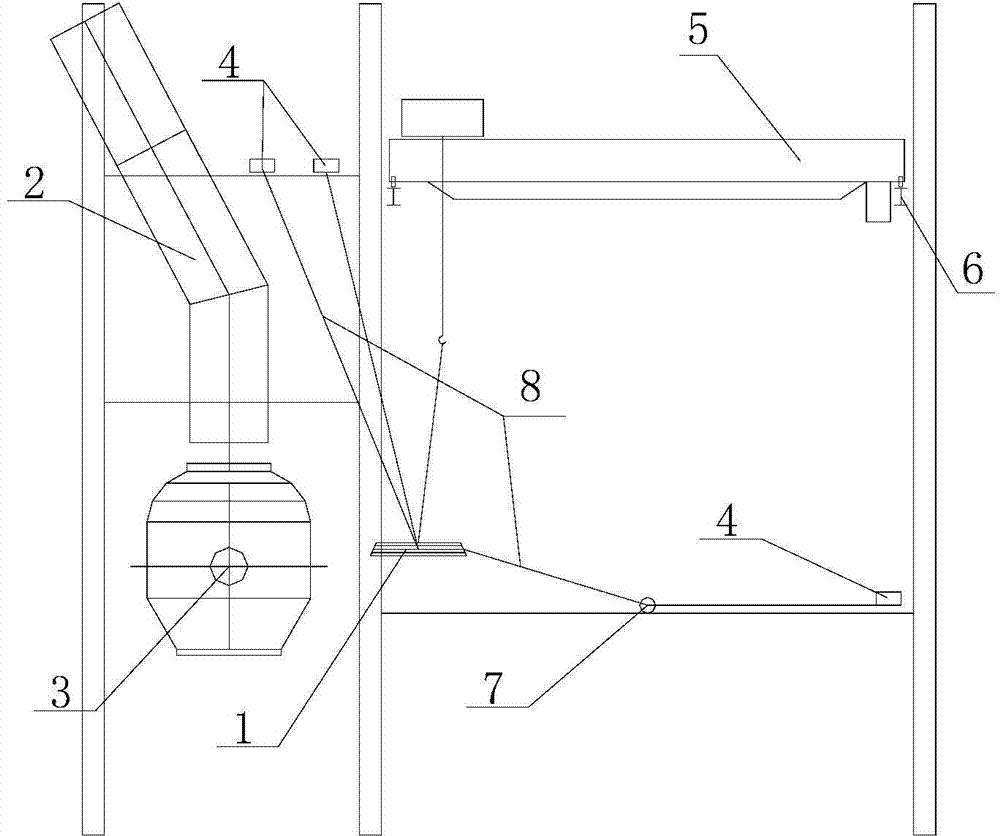

[0019] like Figure 1 to Figure 7 Shown is a construction method for replacing the flue of a steelmaking converter provided by the present invention, which is simple in operation, greatly shortens the construction period, and significantly reduces the replacement cost. Described construction method comprises the following steps,

[0020] First, the group hood 1 of the vaporization flue that needs to be replaced, and the installation center and the elevation of the fixed hood section 2 connected to the group hood 1 are respectively mapped to the fixed foundation outside the steelmaking converter 3; Lifting equipment 4 is respectively installed on the vertical top and the horizontal outside of the group hood 1; then the group hood 1 and the fixed fume hood section 2 are successively cut and separated from the vaporization flue; then through the The hoisting equipment 4 is hoisted and dismantled with the cooperation of the hoisting machinery 5 arranged outside the steelmaking co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com