A high-quality paper web papermaking process

A papermaking process and high-quality technology, applied in textiles and papermaking, papermaking, papermaking and other directions, can solve the problems of no disclosure of papermaking machinery or papermaking system papermaking process, reduced paper quality, and different thicknesses, etc., to avoid clogging, improve Quality, improve retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

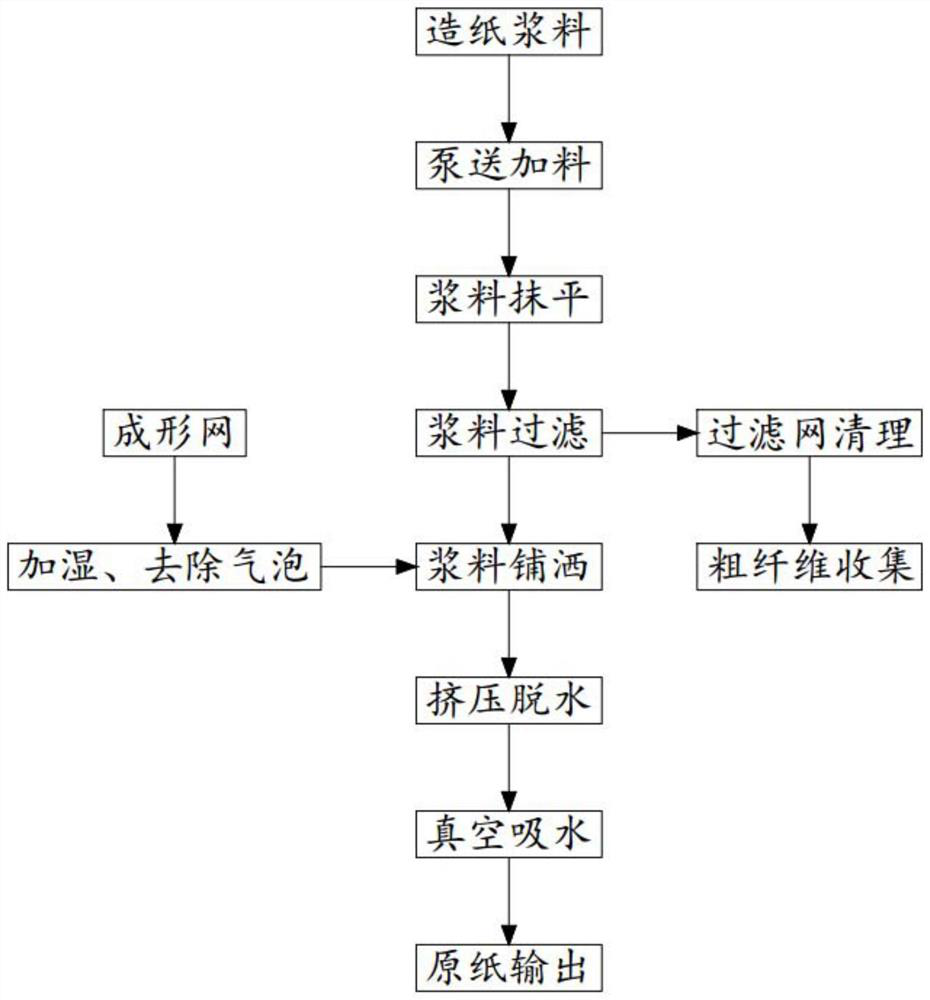

[0044] like figure 1 As shown, a high-quality paper web papermaking process, including:

[0045] Step 1, the feeding process, the papermaking slurry is pumped from the slurry tank 411 to several feeding pipes 412 by the feeding pump 413, and sprayed on the filter area 31 of the filter screen 3 by the feeding pipe 412;

[0046] Step 2, smoothing process, the papermaking slurry reaching the filter area 31 is rolled and smeared by the smoothing roller 422 rolling back and forth along the chute 4211;

[0047] Step 3, the filtering process, the papermaking slurry smoothed by the smoothing roller 422 passes through the filter area 31 of the filter screen 3, and the papermaking slurry is filtered by the filter area 31 and sprinkled on the forming wire 2;

[0048] Step 4, water squeezing process, the papermaking slurry sprinkled on the forming wire 2 is driven by the forming wire 2 to the water squeezing station at the rear side of the filter area 31, and the dewatering motor 52 driv...

Embodiment 2

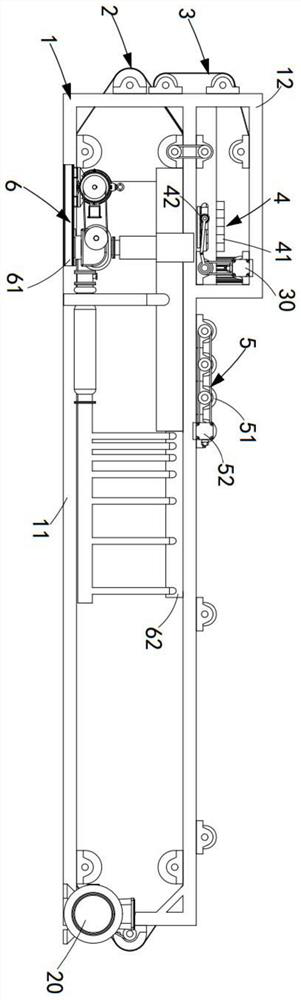

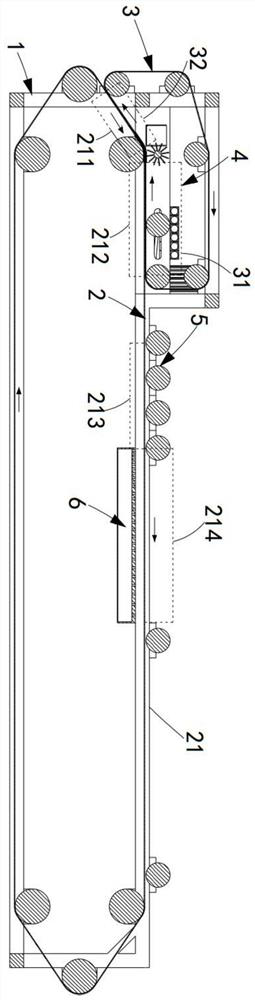

[0065] Such as figure 2 and image 3 As shown, a high-quality paper web papermaking system includes a frame 1, the frame 1 is L-shaped, it includes a first installation part 11 arranged horizontally and a second installation part 12 arranged vertically, and also includes:

[0066] The forming wire 2, the forming wire 2 is arranged horizontally around the first installation part 11, and forms an endless wire ring, which is uniformly distributed meshes, and its upper area forms a papermaking area 21;

[0067] The filter screen 3, the filter screen 3 is horizontally arranged on the second installation part 12, and forms an endless mesh ring, which is located above the input end of the papermaking area 21, and it is uniformly distributed. The mesh number of the net 3 is larger than the mesh number of the forming screen 2, and the conveying direction of the lower end area of the filter mesh 3 is opposite to the conveying direction of the papermaking area 21;

[0068] A feeding...

Embodiment approach

[0103] Such as figure 2 As shown, as a preferred embodiment, the dehydration device 5 includes:

[0104] A plurality of dehydration rollers 51, both ends of the dehydration rollers 51 are installed on the first mounting part 11 in rotation, they are equidistantly arranged above the dehydration zone 213 along the conveying direction of the dehydration zone 213, and along the The conveying direction of the dehydration zone 213, the vertical distance between the dehydration roller 51 and the dehydration zone 213 changes from large to small; and

[0105] A dehydration motor 52 , the dehydration motor 52 is arranged on one side of the first installation part 11 , and it is connected to any one of the dehydration rollers 51 in transmission, and drives the other dehydration rollers 51 to rotate through a belt transmission.

[0106] It should be noted that, in the process of squeezing and dehydrating the slurry by the dewatering roller 51, due to the gradual decrease of the moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com