Technique of alkaline process for producing sodium methoxide/sodium ethylate

A technology of sodium ethoxide and alkali method, applied in the field of alkali production of methyl ethylate/sodium ethoxide, can solve the problems of inconvenient automatic production, low production efficiency, long production cycle and the like, and achieve the effects of shortening production cycle, high production efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

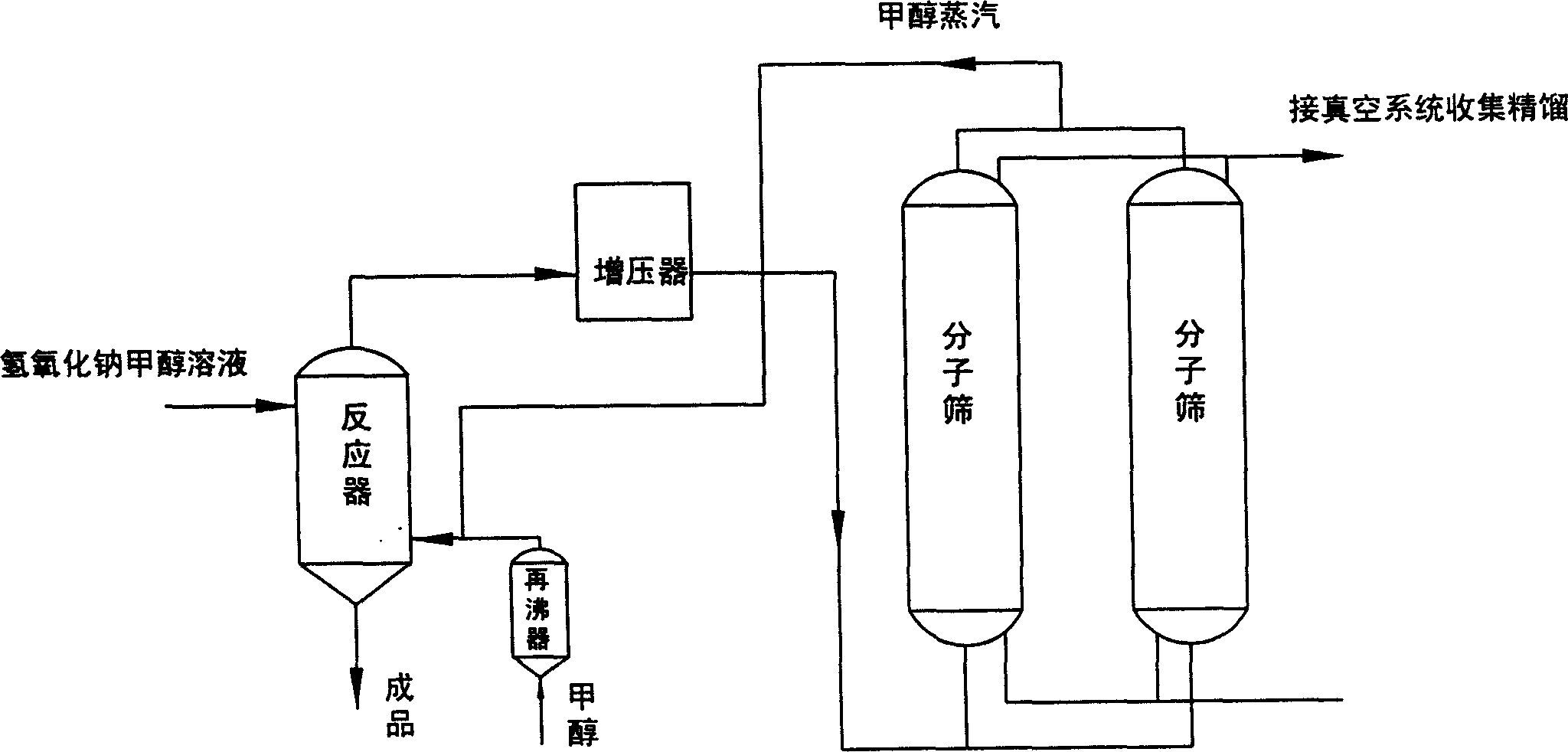

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0015] In the process of producing sodium methoxide by the alkaline method of the present invention, the methanol vapor produced by the reboiler carries the dehydrated methanol gas and 50-80% sodium hydroxide methanol solution into the reactor continuously, and the water-containing methanol vapor produced by the reaction is After being pressurized to about 0.17Mpa by the supercharger, it enters from the bottom of the molecular sieve I for dehydration. In the molecular sieve I, water is absorbed by the micropores of the molecular sieve (containing about 25% methanol), and methanol with a content of more than 99.8% is obtained from the top of the molecular sieve I The gas returns to the reactor to continue to participate in the reaction; when the adsorption of molecular sieve I is close to saturation, switch to molecular sieve II to continue the adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com