Multiple combination oil soluble demulsifier

A demulsifier and compound oil technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of poor broad spectrum, high cost, high oil content in dehydrated water, and achieve good dehydration effect, low cost and broad spectrum. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] 2. Preparation of polyether with higher fatty alcohol as initiator

[0024] In the autoclave, add starter higher aliphatic alcohol, 0.1% catalyst potassium hydroxide, under the conditions of temperature 130-150°C and pressure 2-4MPa, ethylene oxide, propylene oxide, ethylene oxide alkane, the mol ratio of the front and back of ethylene oxide is 1:3. After heat preservation for 4-6 hours, cool, filter, and refine to obtain polyether with higher fatty alcohol as the initiator. Then, the polyether with higher fatty alcohol as the initiator is reacted with stearic esterification for 4 hours under the condition of catalyst p-toluenesulfonic acid at a temperature of 120-130°C and a pressure of 0.1MPa, wherein the higher fatty alcohol The molar ratio of polyether and stearic acid as the initiator is 1.1:1.

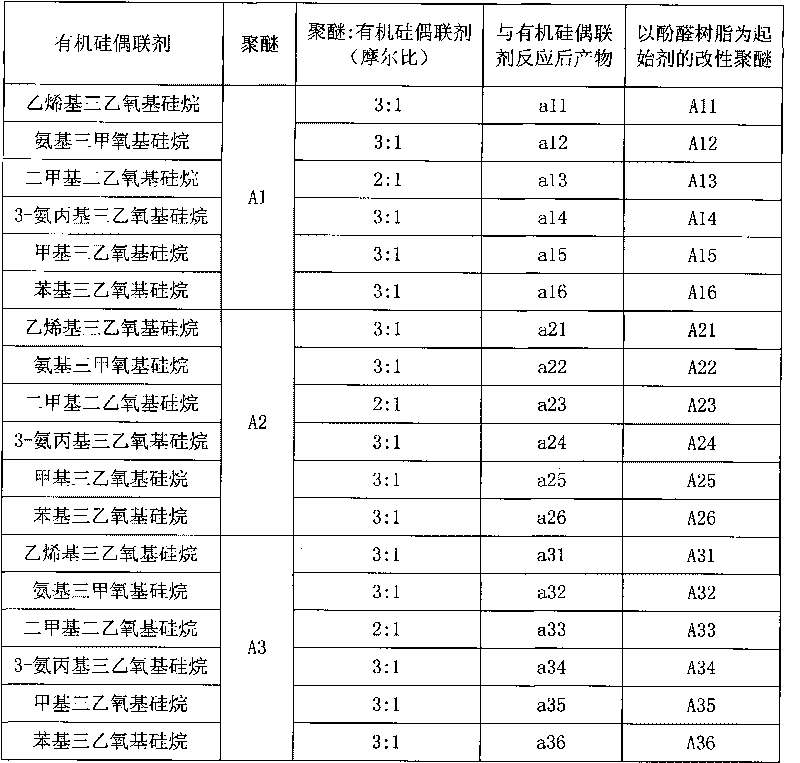

[0025] Table 3 Preparation of Polyether B1~B3 with Higher Fatty Alcohol as Initiator

[0026] initiator

[0027] Table 4 Preparation of modified polyether B11...

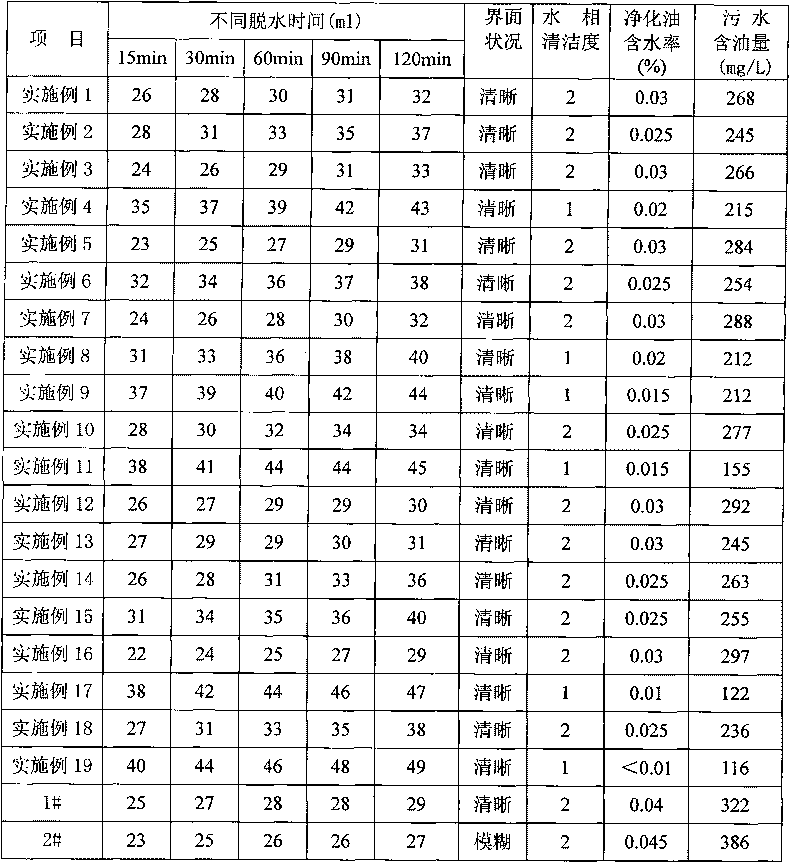

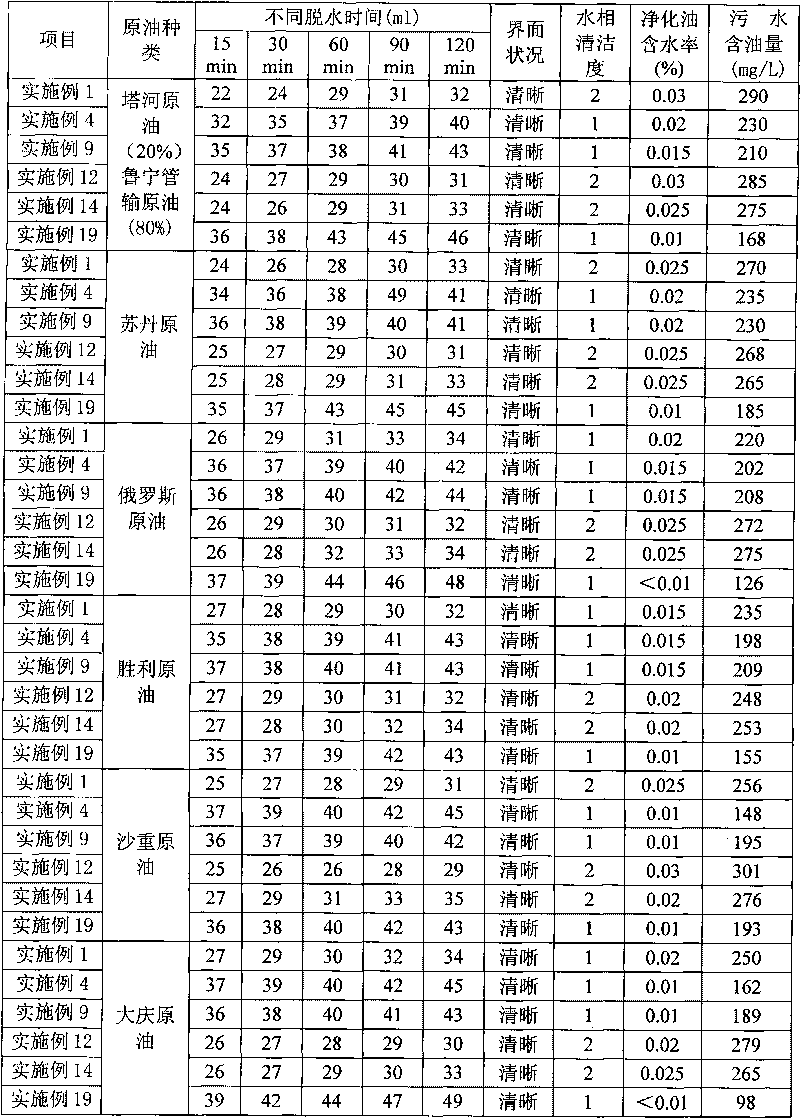

Embodiment 1

[0032] 40g demulsifier: 27g A11, 13g B11; 8g fluorine-containing surfactant: sodium perfluorononenyloxybenzenesulfonate; 52g solvent: C10 heavy aromatic hydrocarbon.

Embodiment 2

[0034] 36g demulsifier: 22g A12, 14g B12; 10g fluorine-containing surfactant component: sodium perfluorononenyloxybenzenesulfonate; 54g solvent: C10 heavy aromatic hydrocarbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com