Waste heat utilization steel strip heat treatment system

A heat treatment system and steel strip technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as energy waste, deterioration of factory production environment, etc., and achieve the effect of reducing production costs and heating energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

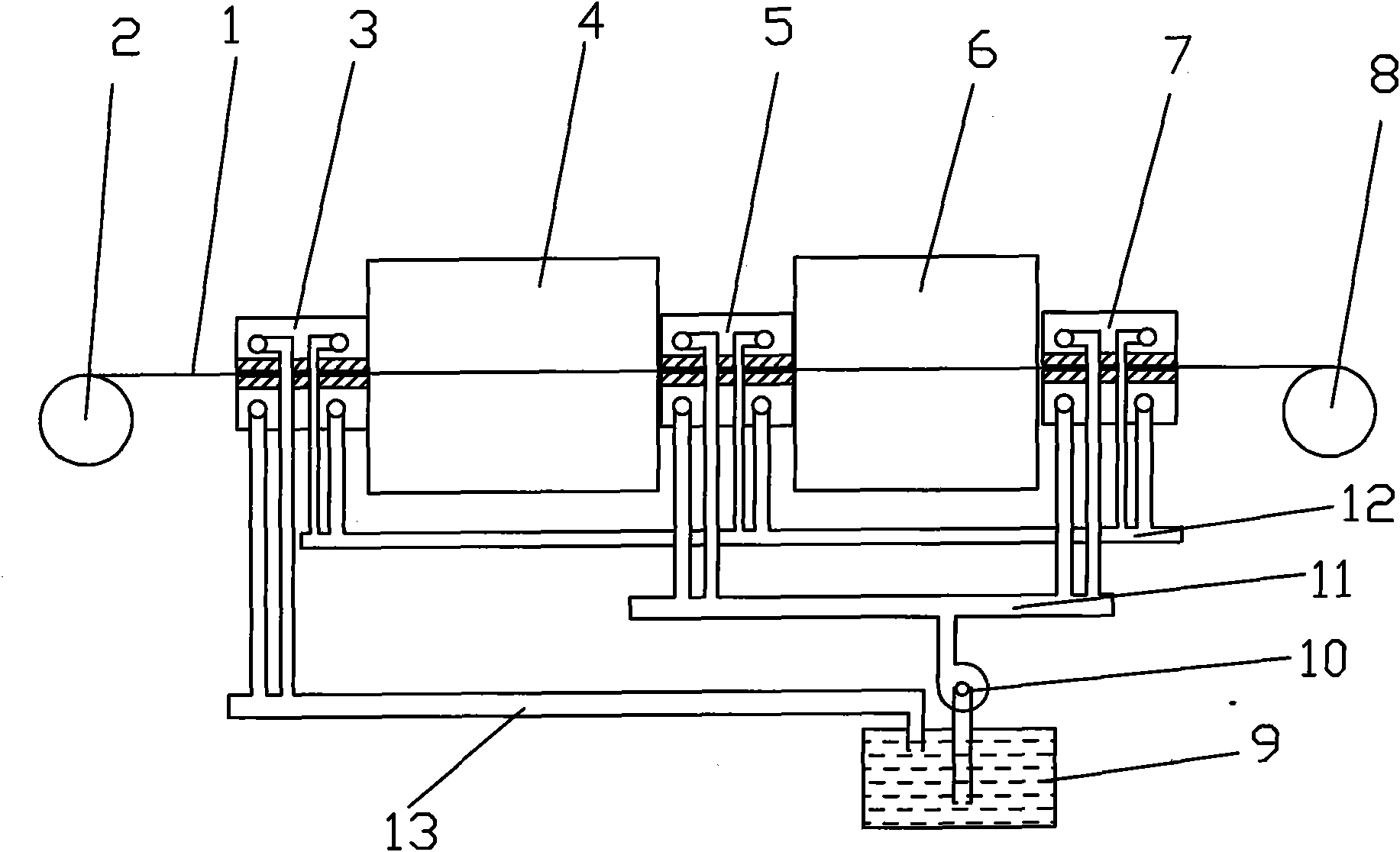

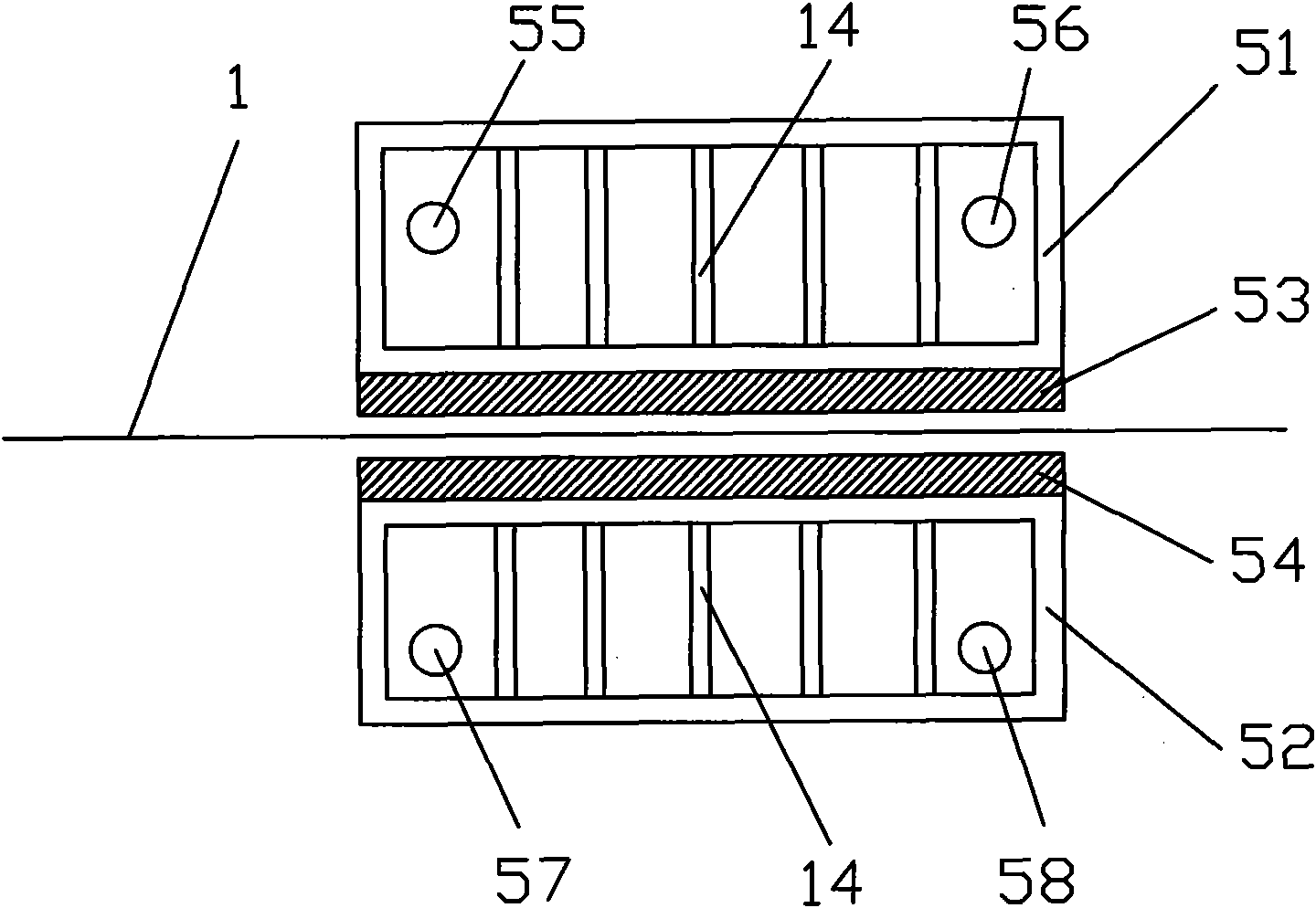

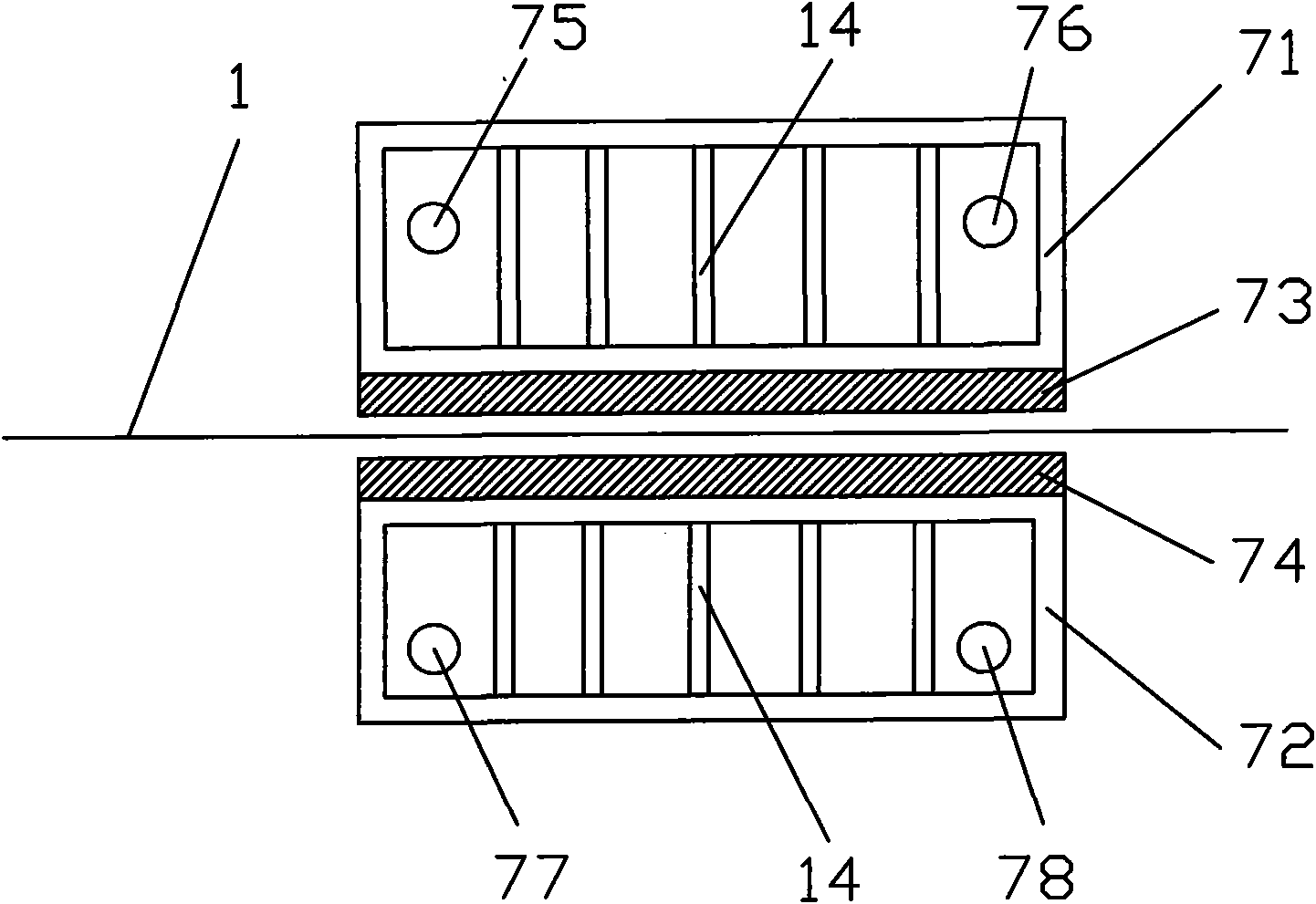

[0017] Such as Figure 1 to Figure 4 As shown, a steel strip heat treatment system utilizing waste heat includes a curling wheel 2, a winding wheel 8, a steel strip 1 arranged between the curling wheel 2 and the winding wheel 8, and the curling wheel 2 and the winding wheel A heating furnace 4 and a tempering furnace 6 corresponding to the steel strip 1 are sequentially arranged between the wheels 8, a quenching pressing plate 5 is arranged between the heating furnace 4 and the tempering furnace 6, and a waste heat recovery pressing plate is arranged at the rear of the tempering furnace 6 7. A waste heat utilization press plate 3 corresponding to the quenching press plate 5 and the waste heat recovery press plate 7 is provided at the front of the heating furnace 4 . The quenching press plate 5 includes a first upper water tank 51 and a first lower water tank 52 arranged on both sides of the steel strip 1, the bottom of the first upper water tank 51 is provided with a first upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com