Method for producing pig iron and phosphate using ferro-phosphorus

A technology of ferrophosphorus and pig iron, applied in phosphoric acid, phosphorus oxyacids, etc., which can solve problems such as high reaction temperature, uncontinuous production process, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

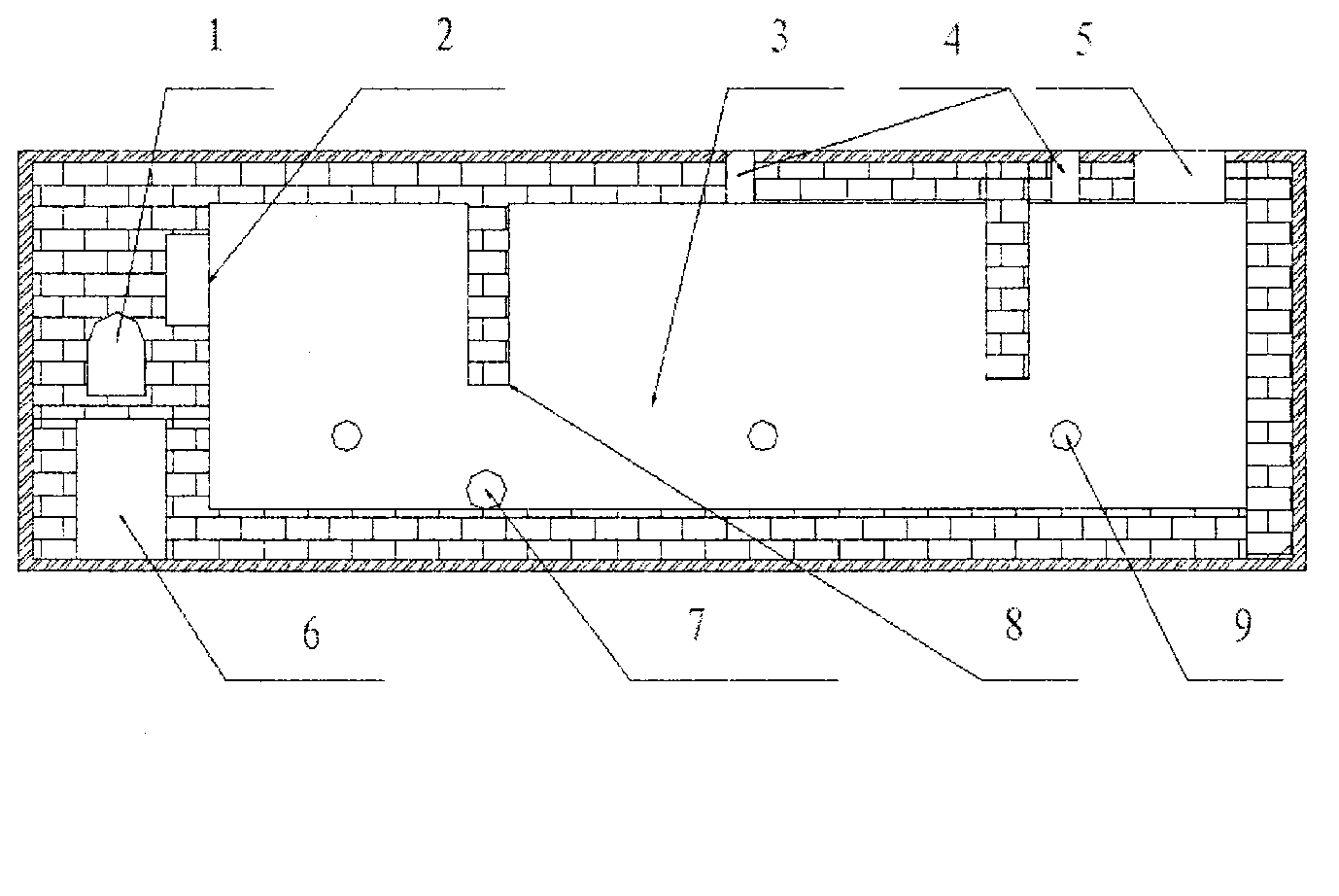

[0011] Add a match (or spray diesel oil, coal powder, etc.) through the fuel inlet mark 1 of the reverberatory furnace and ignite the fire, turn on the induced draft fan, let the air naturally enter the furnace from the furnace door and ash pit, accelerate combustion, and the burning flame starts from mark 2 Enter the marked 3 reaction furnace to heat the ferrophosphorus. After the combustion is normal, you can continue to add lump coal (or inject diesel oil, coal powder) from mark 1 to accelerate combustion. When the iron phosphorus in the furnace starts to melt, gradually blow hot air or oxygen-enriched air into the iron phosphorus in the furnace through the mark 9 to oxidize the phosphorus element. With large air blowing volume, the optimum reaction temperature in the reverberatory furnace is kept at 1300-1600°C. After the furnace temperature is normal, continuously add ferrophosphorus into the furnace and blow in hot air or oxygen-enriched air for rapid blowing oxidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com