Industrial organic waste gas treatment method and device based on oxyhydrogen gas combustion

A technology for organic waste gas and waste gas treatment, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of narrow catalyst application range, large volume of the whole set, easy poisoning of catalyst, etc., to speed up the oxidation reaction and solve the problem of easy poisoning. , the effect of small air coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

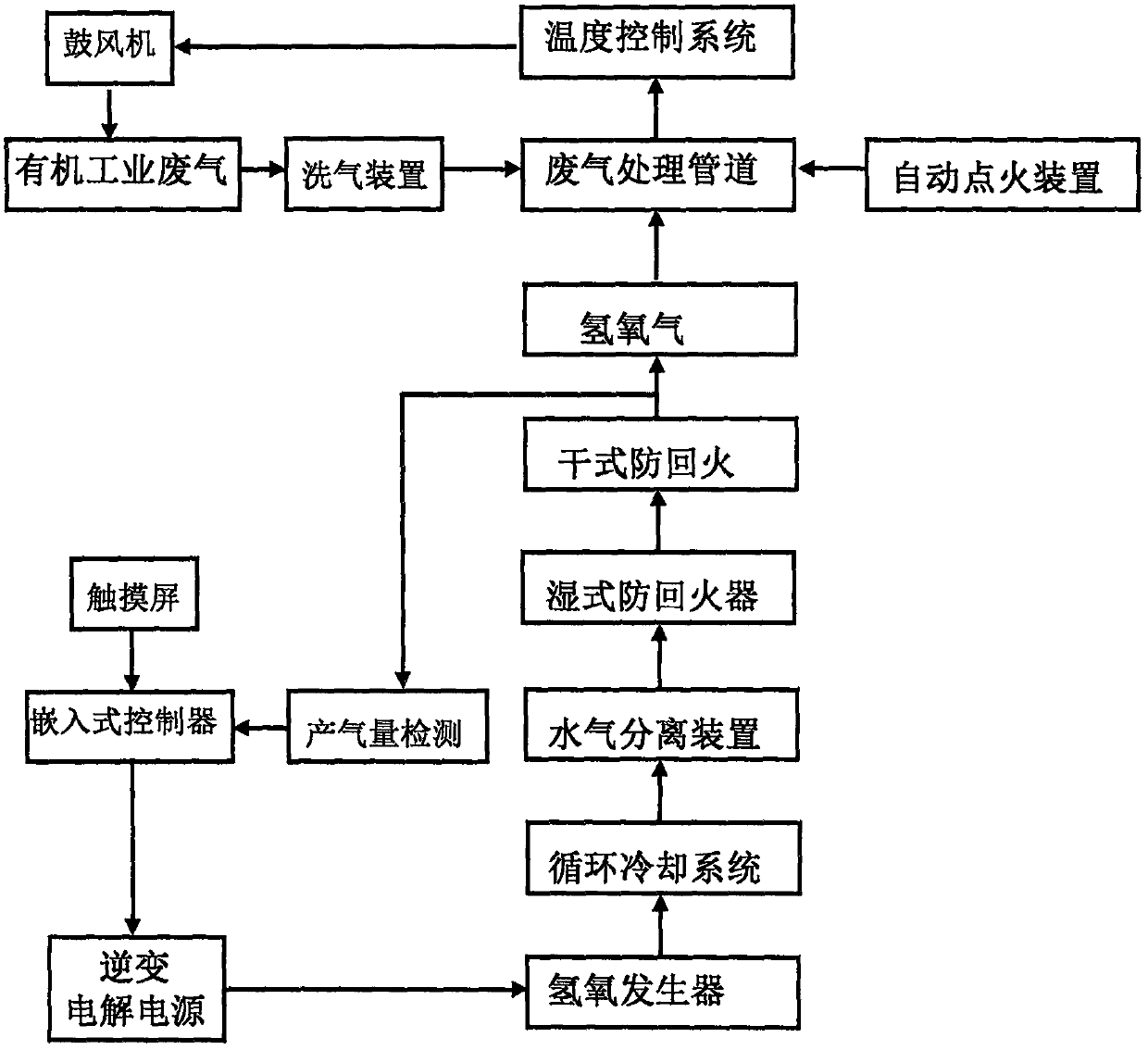

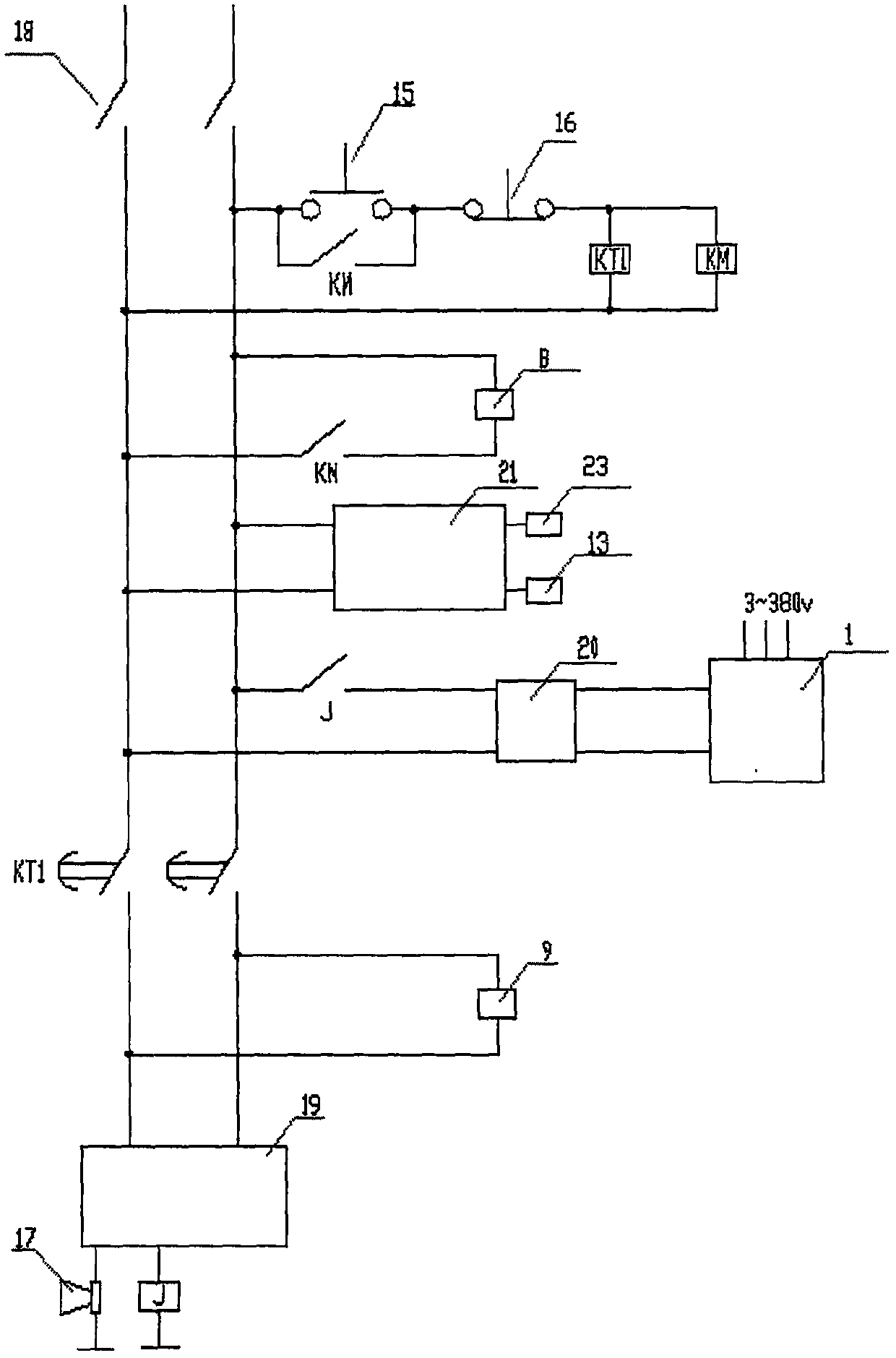

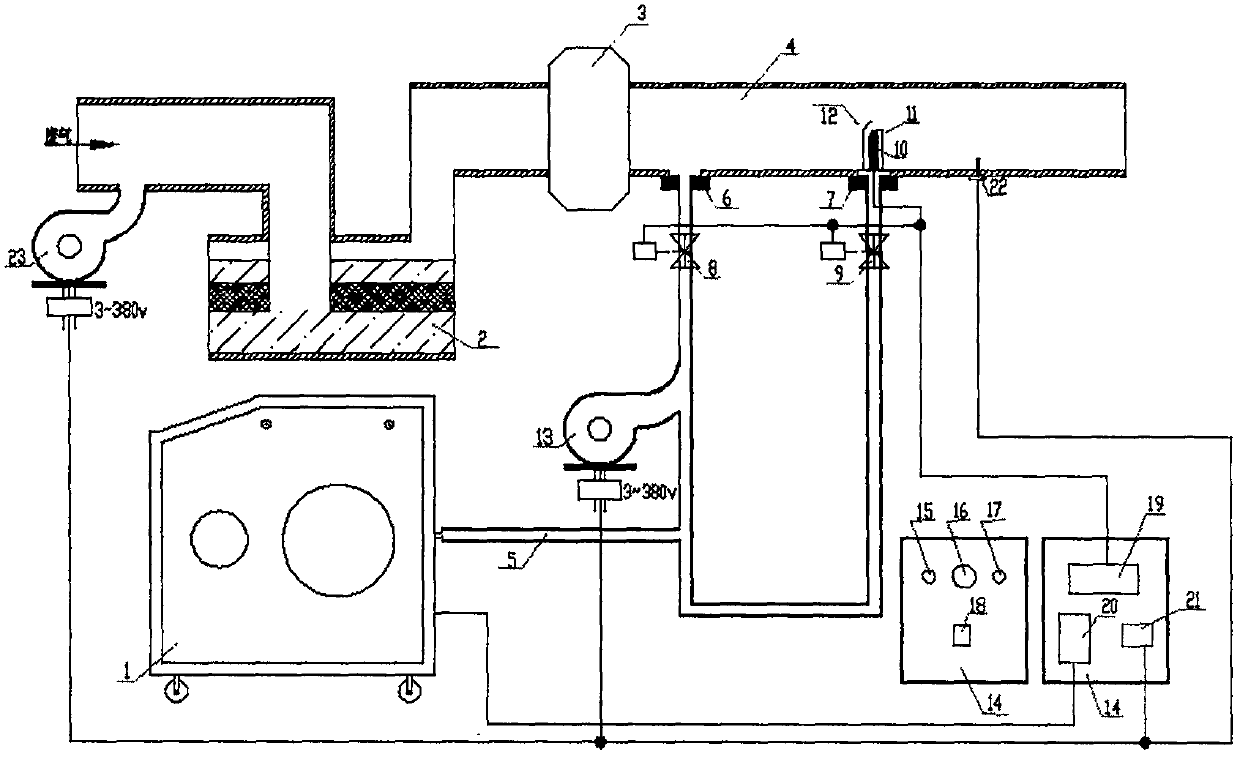

[0028] Such as image 3 As shown, an industrial organic waste gas treatment device based on hydrogen-oxygen combustion of the present invention includes a water electrolysis hydrogen-oxygen system, a three-way pipeline and a connecting flange, an automatic igniter, a hydrogen-oxygen blowing system, and a temperature detection system for waste gas treatment pipelines. Interlocking control circuit with control system, combustion and water electrolysis hydrogen oxygen system.

[0029] The water electrolysis hydrogen and oxygen system 1 enters the exhaust gas treatment pipeline 4 through the gas washing and liquid sealing device 2 and the dry backfire preventer 3, and is connected with the exhaust gas treatment pipeline through the three-way pipeline 5 and flanges 6 and 7. The catalyst output pipe end and the ignition fuel end of the three-way pipeline are equipped with electromagnetic valves 8 and 9 respectively, and a burner 10, an arc needle 11 and a successful ignition detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com