Easy compact asphalt mixing material and preparation method of easy compact asphalt mixing material

A kind of asphalt mixture, dense technology, applied in the field of asphalt mixture, can solve the problems such as the control temperature does not meet the actual requirements, the effect of cooling effect, complex production process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

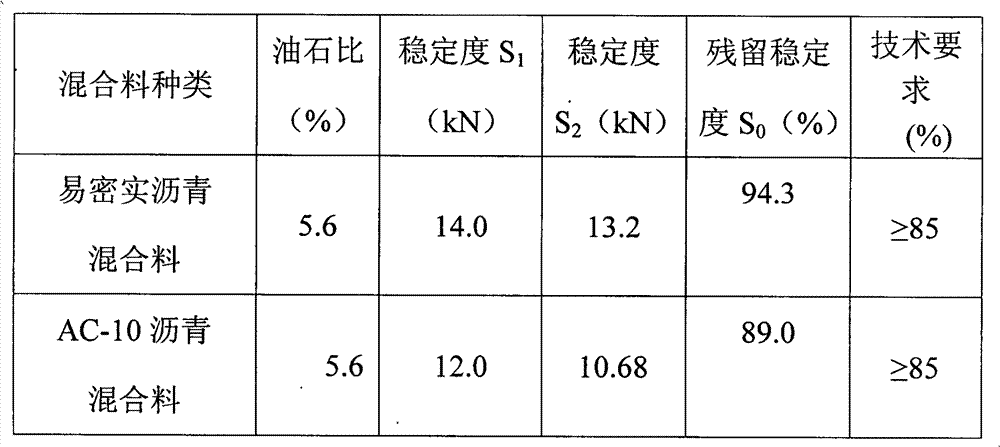

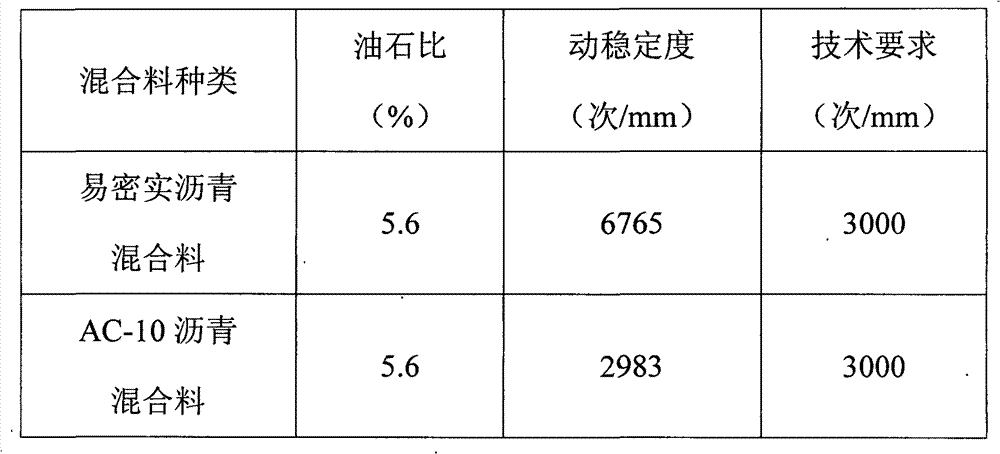

[0025] The present invention will be described in detail below according to the embodiments.

[0026] According to the ratio of basalt 8-11mm gravel: basalt 5-8mm gravel: basalt machine-made sand: limestone powder = 54:14:27:5, see Table 1 for details;

[0027] The above-mentioned mineral materials are calculated in 100 parts, and other components are prepared according to the ratio of 5.6 parts of SBS modified asphalt, 0.2 part of polyester fiber, and 0.3 part of compacting agent;

[0028] According to the above formula, through the ACP-T4000 mixer, heat the mineral material to 155°C, and put it into the mixing tank together with the polyester fiber for 6 seconds; heat the modified asphalt to 170°C, and spray it into the mixing tank; 3 Seconds later, spray the compacting agent and stir for 13 seconds; add mineral powder and continue to stir for 40 seconds, and control the temperature out of the vat to 145°C. Easy to compact asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com