Zero-heat carrier powdered coal low-temperature dry distillation carbonization method

A pulverized coal, low-temperature technology, applied in the field of coal dry distillation, can solve the problems of uneven transmission of heat and temperature to materials, difficulty in separation of powder and coke, and small space between materials, and achieve the effect of safe use, simple process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

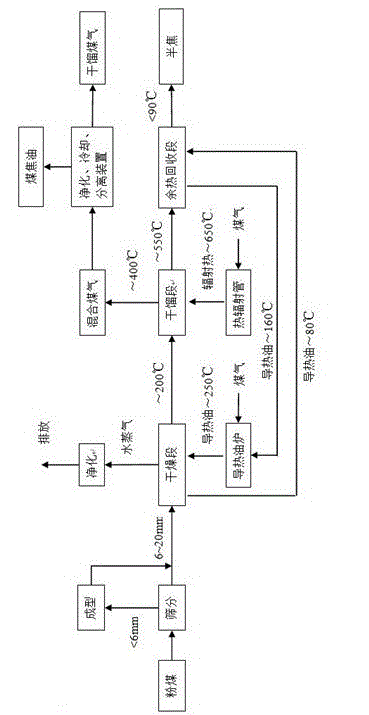

[0020] A low-temperature dry distillation method for pulverized coal without heat carrier. The method is carried out in a closed walking furnace, and the process sections of the walking furnace are separated by sealing devices to avoid the mutual influence of gases in each section and ensure that the The stability of the working temperature and the dry distillation gas concentration are not affected by the exhaust gas in the drying section.

[0021] The walking furnace is divided into a drying section, a dry distillation section and a waste heat recovery section. The heat transfer oil in the heat transfer oil furnace dries the pulverized coal and recovers waste heat, and the gas radiant tube performs dry distillation of the pulverized coal.

[0022] like figure 1 As shown, the concrete steps of this heat carrier-free pulverized coal low-temperature dry distillation method are as follows:

[0023] Step 1, screening; screen the pulverized coal directly from the coal mine with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com