Temperature controlling valve

A technology for temperature control valves and valves, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as higher manufacturing process requirements, lower reliability of heating devices and valves, failure and damage of valves and heating devices, etc., to achieve High reliability and stability, eliminate secondary pollution, and save heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

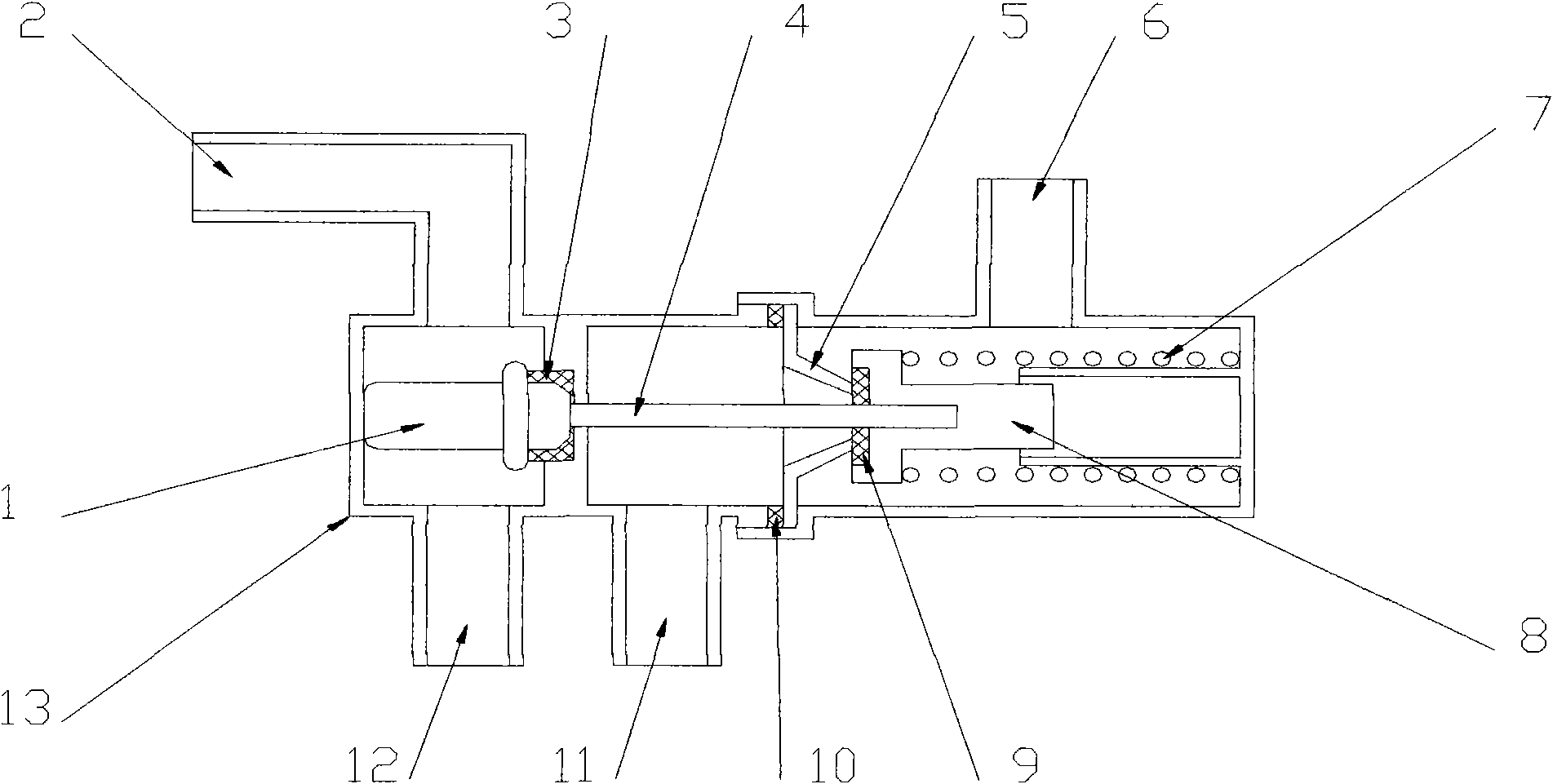

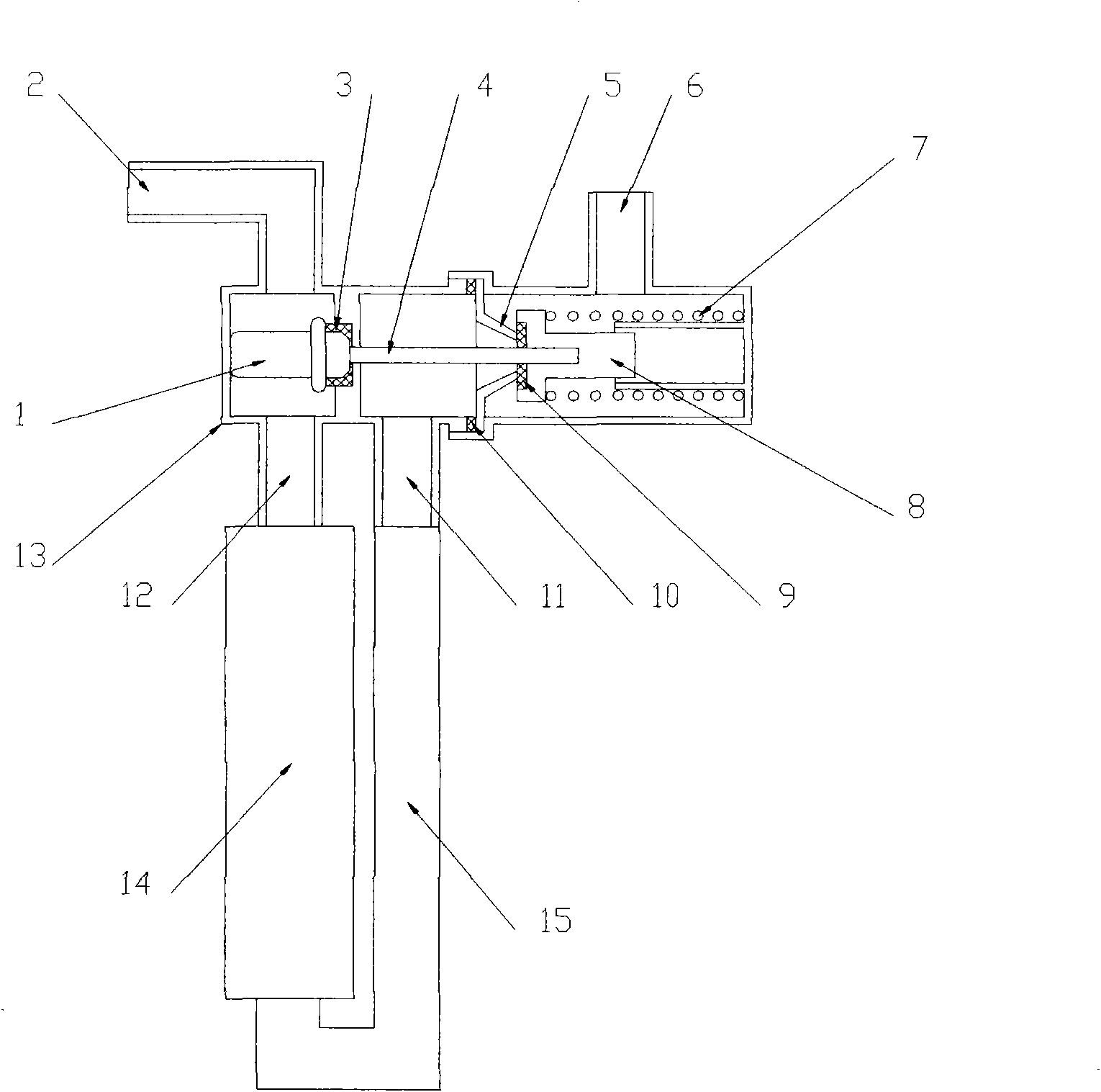

[0012] combined with figure 1 And attached figure 2 Be specific.

[0013] In the figure, 1 is the thermal element temperature sensing body, 2 is the hot water outlet, 3 is the sealing ring, 4 is the power rod of the thermal element, 5 is the valve seat, 6 is the cold water inlet, 7 is the compression spring, and 8 is the valve. Core, 9, valve core gasket, 10, valve seat gasket, 11, cold water outlet, 12, hot water inlet, 13, valve body, 14, heating device, 15, connecting water pipe.

[0014] When the heating device 14 is heated, the temperature of the water in the heating device is heated, and the thermal element temperature sensing body 1 feels that when the temperature of the hot water rises to the temperature of the opening valve set by the temperature control valve, the thermal element power rod 4 The action pushes the valve core 8 and the valve core gasket 9 away from the valve seat 5, and the valve is opened. At this time, cold water enters the valve body 13 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com